Device for detecting carbon content of fly ash in coal-fired power generation boiler

A technology for fly ash carbon content and power generation boilers, applied in measuring devices, weighing by removing certain components, instruments, etc., can solve the problems of low measurement accuracy and reliability, and achieve full contact reaction with O2 , Increase the sintering temperature, improve the effect of measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

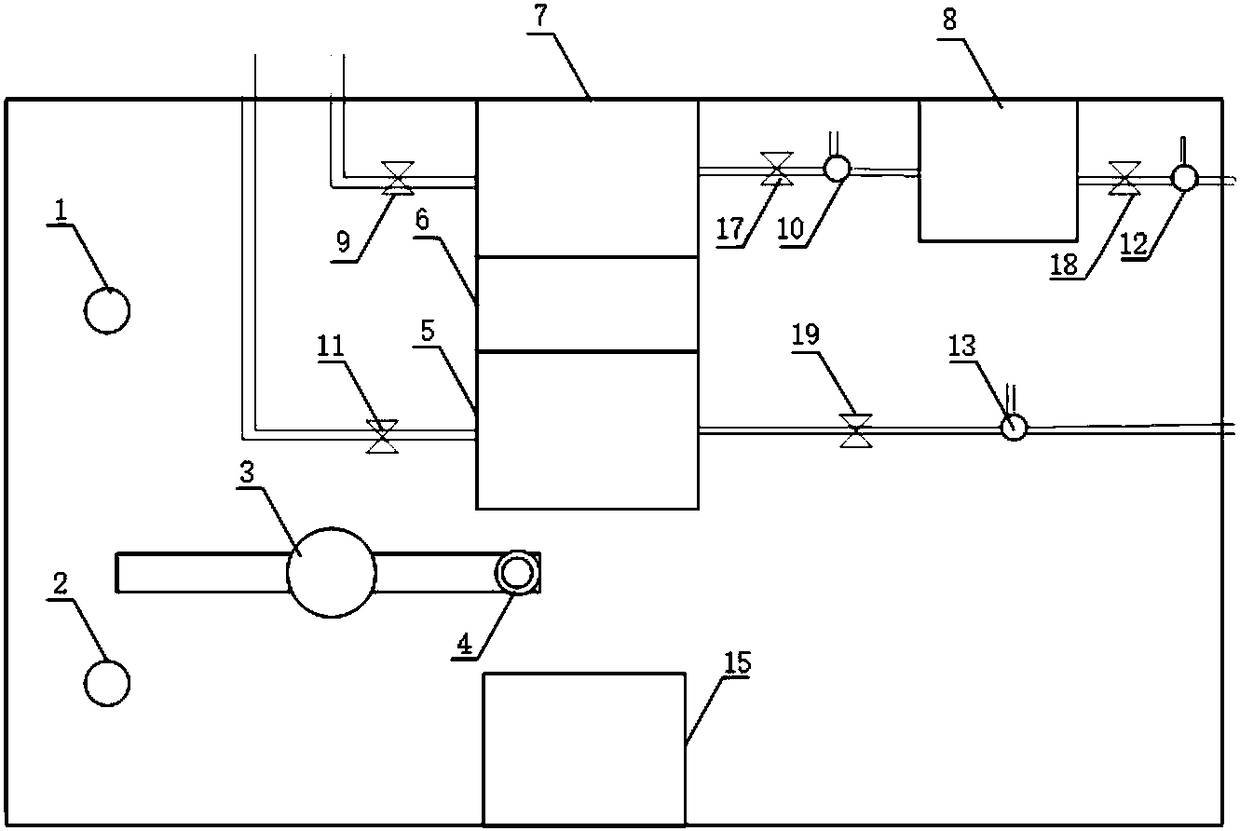

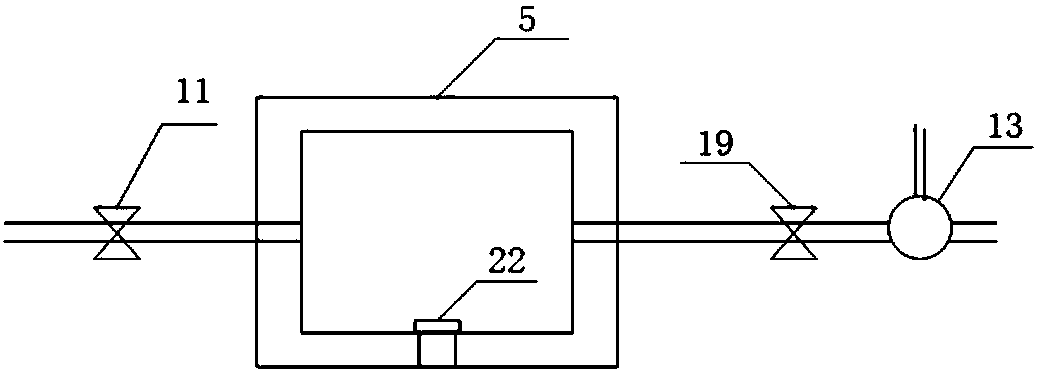

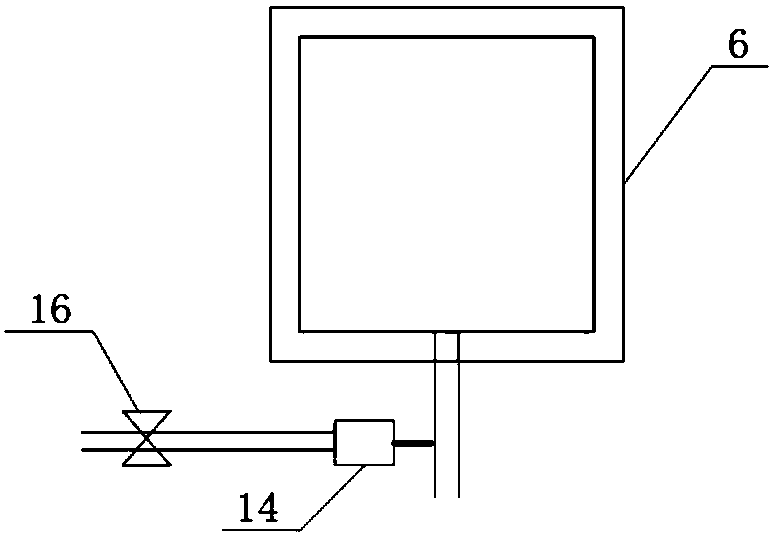

[0043] refer to Figure 1-7 The coal-fired power generation boiler fly ash carbon content detection device of the present embodiment includes: a drying furnace 5, one end of the drying furnace 5 is connected with an inert gas supply mechanism through a pipeline, and the other end of the drying furnace 5 is connected with a vacuum pump-13 through a pipeline Burning furnace 7, one end of burning furnace 7 is connected with oxygen supply mechanism through pipeline, the other end of burning furnace 7 is connected with one end of sealed container 8 through pipeline, and the other end of sealed container 8 is connected with vacuum pump 212 through pipeline ; Burning container 4; lifting rotating tray 3, the lifting rotating tray 3 is used to transport the burning container 4; solid particle container 6, the lower end of the solid particle container 6 is connected with a blanking channel, and the blanking channel is provided with an opening and closing valve ; gas channel; the gas ch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com