Automatic tank dumping system for torpedo type molten iron vehicle tilting device and technological method thereof

A mixed-rail car and automatic technology, which is applied in the configuration of manufacturing tools, metal processing equipment, indicating equipment/measuring equipment, etc. Influence problems such as large impact, to achieve the effect of preventing personnel safety accidents, improving production safety, and operating safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with the accompanying drawings.

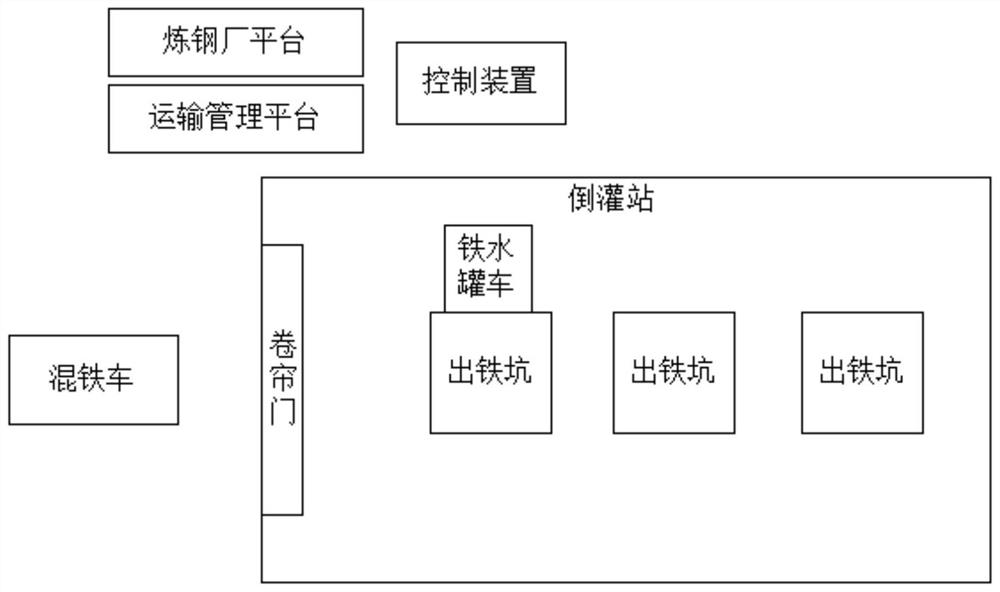

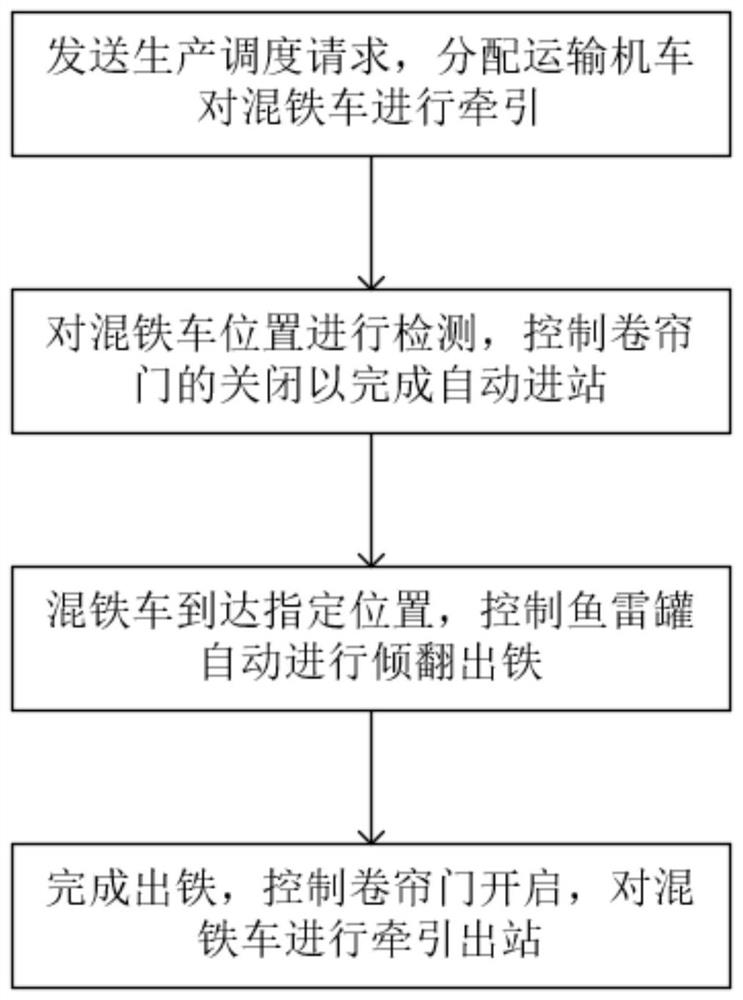

[0039] The ironmaking and steelmaking units of large steel plants in my country are usually arranged separately. The molten iron produced by the blast furnace is generally transported to the steelmaking dumping station by torpedo-type mixed iron truck. Put it into the molten iron tank, and after it is filled with molten iron, the molten iron tank is lifted to the next process by a crane.

[0040] In the conventional design, there are generally 2 to 3 tap pits in the dumping station, and a mixed iron car railway line is set on each side of the tap pit, and a molten iron tank car is installed in each tap pit, and the car is equipped with a weighing machine. The device can accurately measure the weight of molten iron. There is a dust cover above the tap pit to remove dust when pouring molten iron. The tap pit is also equipped with a temperature measurement and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com