Operation method for reducing iron loss of molten iron torpedo ladle

An operation method and technology of torpedo tanks, which are applied in the field of iron consumption reduction of molten iron torpedo tanks, can solve the problems of increased slag in the furnace, increased consumption of steel materials, increased production costs, etc., to reduce the consumption of molten iron, increase production, and stir powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

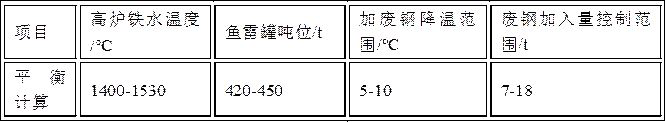

[0020] An operating method for reducing iron consumption of hot metal torpedo tanks. The scrap steel is processed into crushed materials by crushing. The size is required to be within 100×100mm, and the specific gravity of the crushed material pile is >1.60t / m. 3 , Transport the scrap steel to the torpedo tank for the iron level silo, and calculate the amount of scrap added to meet the steelmaking temperature requirements according to the blast furnace hot metal tapping temperature. The blast furnace hot metal temperature / ℃ 1400-1530, torpedo tank tonnage / t 420-450, plus Scrap cooling range / ℃ 5-10, scrap steel addition control range kg / t 7-18, the blast furnace uses a rotating chute to add scrap to the torpedo tank in the early stage of iron conversion, and uses the stirring effect of molten iron in the later stage of the torpedo tank to promote the torpedo Melting of scrap steel in the tank.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com