Repairing method for torpedo ladle lining

A repair method and technology for a mixed iron car, which are applied in the directions of casting molten material containers, manufacturing tools, metal processing equipment, etc. Longevity, improved corrosion resistance, improved compaction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

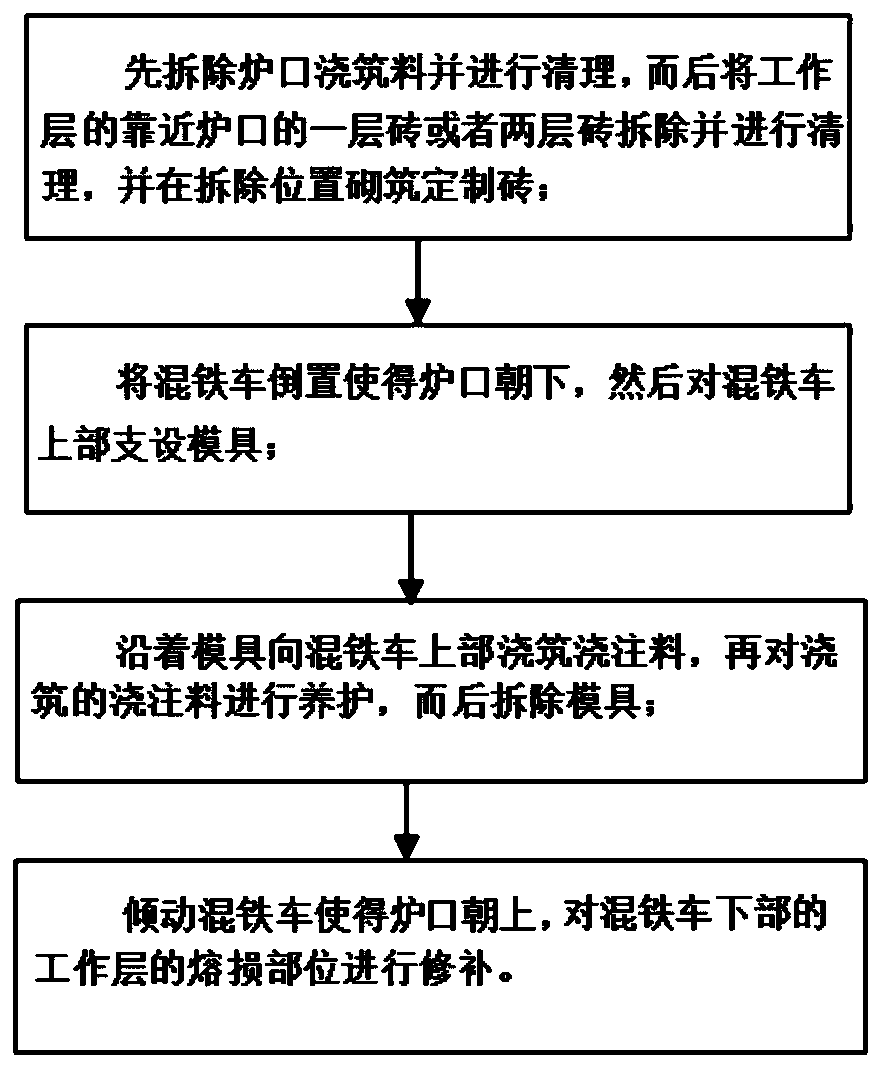

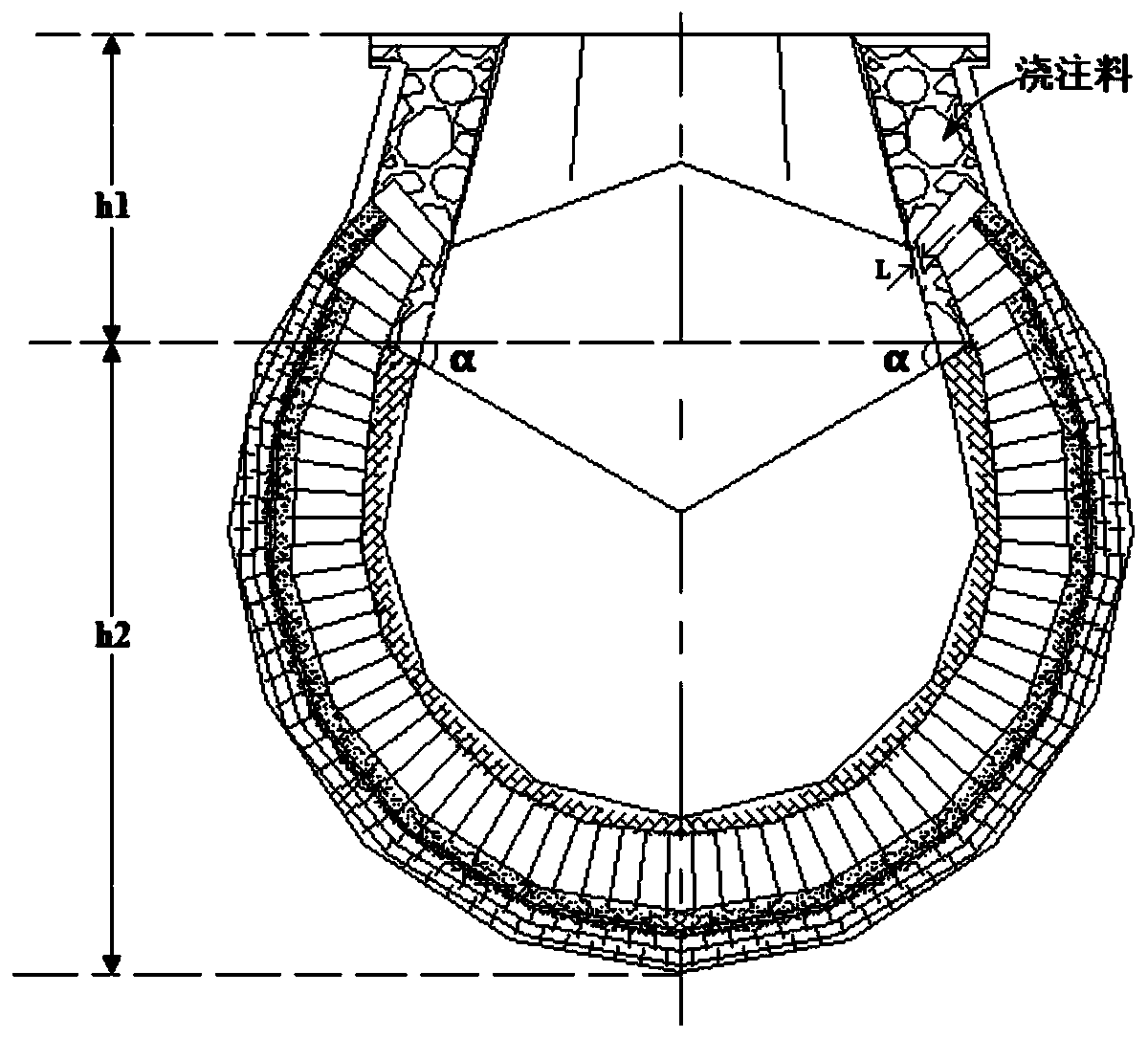

[0029] combine figure 1 As shown, the method for repairing the inner lining of a mixed iron car of the present invention divides the mixed iron car into an upper part and a lower part. ; After that, the furnace mouth of the mixed iron car is turned upward, and the inner lining of the lower part of the mixed iron car is repaired. It is worth noting that in the prior art, the furnace mouth of the mixed iron car is kept upward and poured, resulting in low compactness of the poured castable, which in turn leads to poor quality of the repaired mixed iron car lining; and the present invention By placing the furnace mouth of the mixed iron car facing down and pouring, the compactness of the castable can be improved, and the quality of the inner lining of the mixed iron car can be further improved.

[0030] A kind of method for repairing the lining of mixed iron car of the present invention, concrete steps are as follows:

[0031] (1) Remove the pouring material at the furnace mouth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com