Torpedo for extruder

A torpedo head and extruder technology, applied in the field of extruders, can solve the problem of small mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

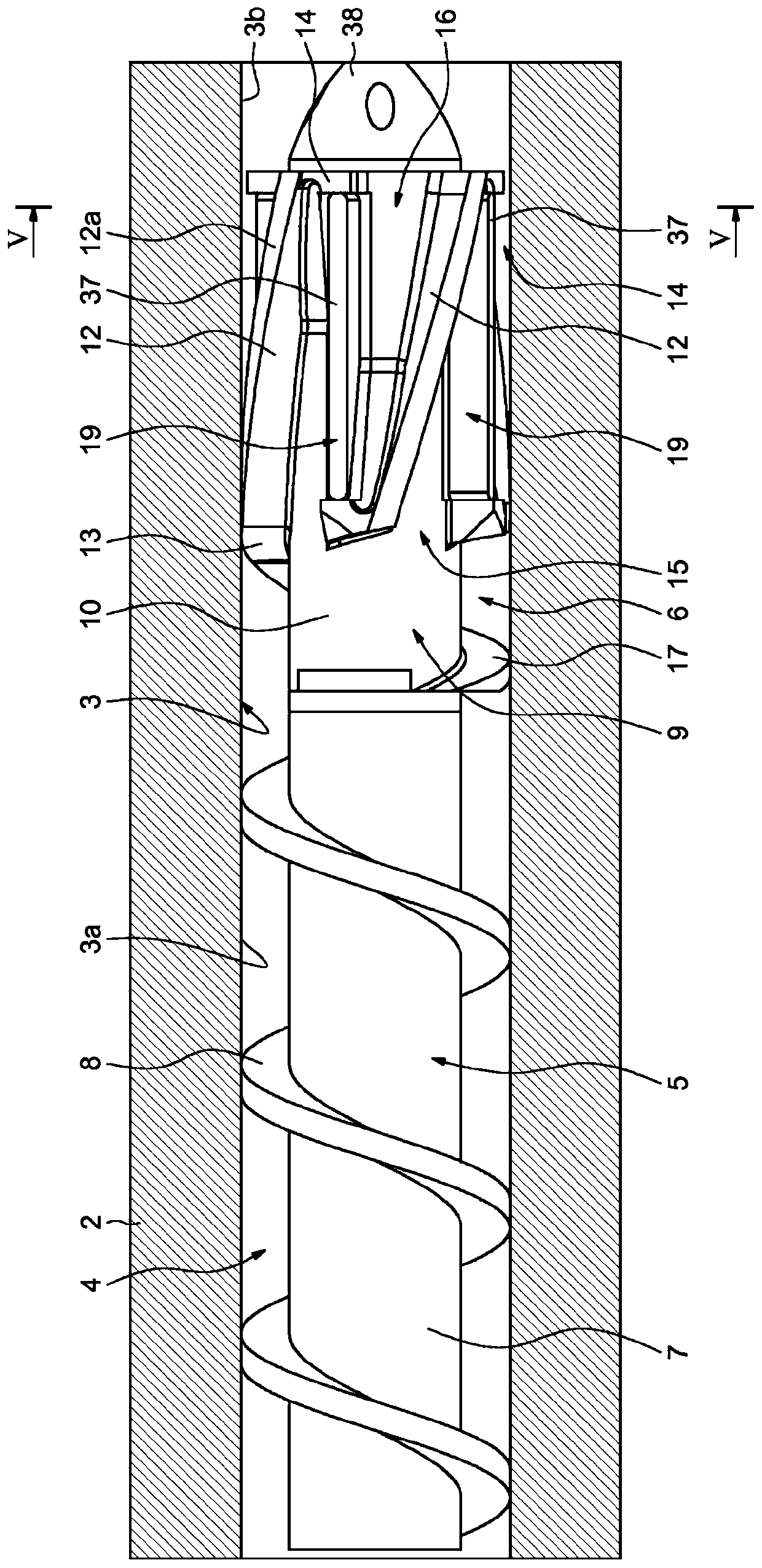

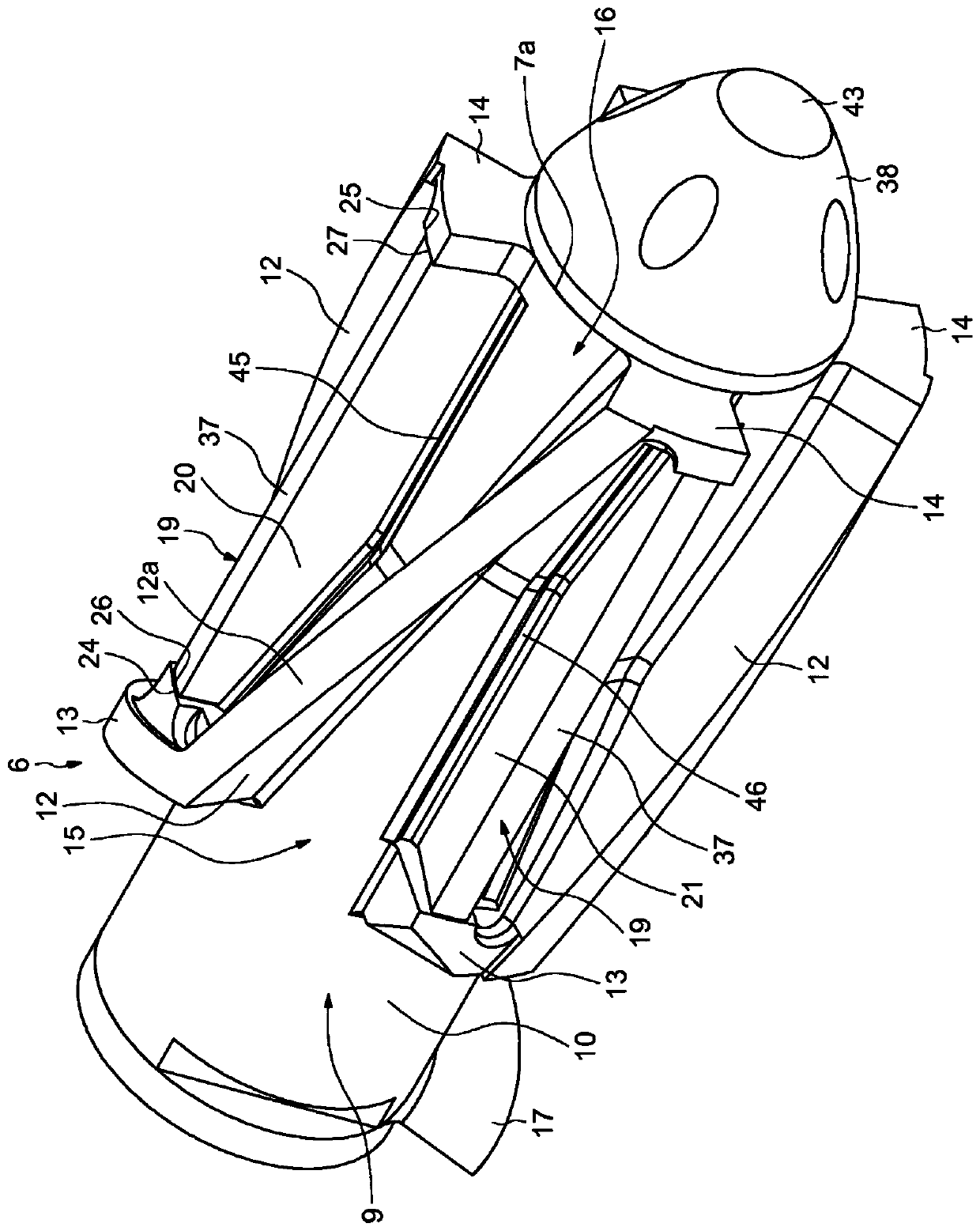

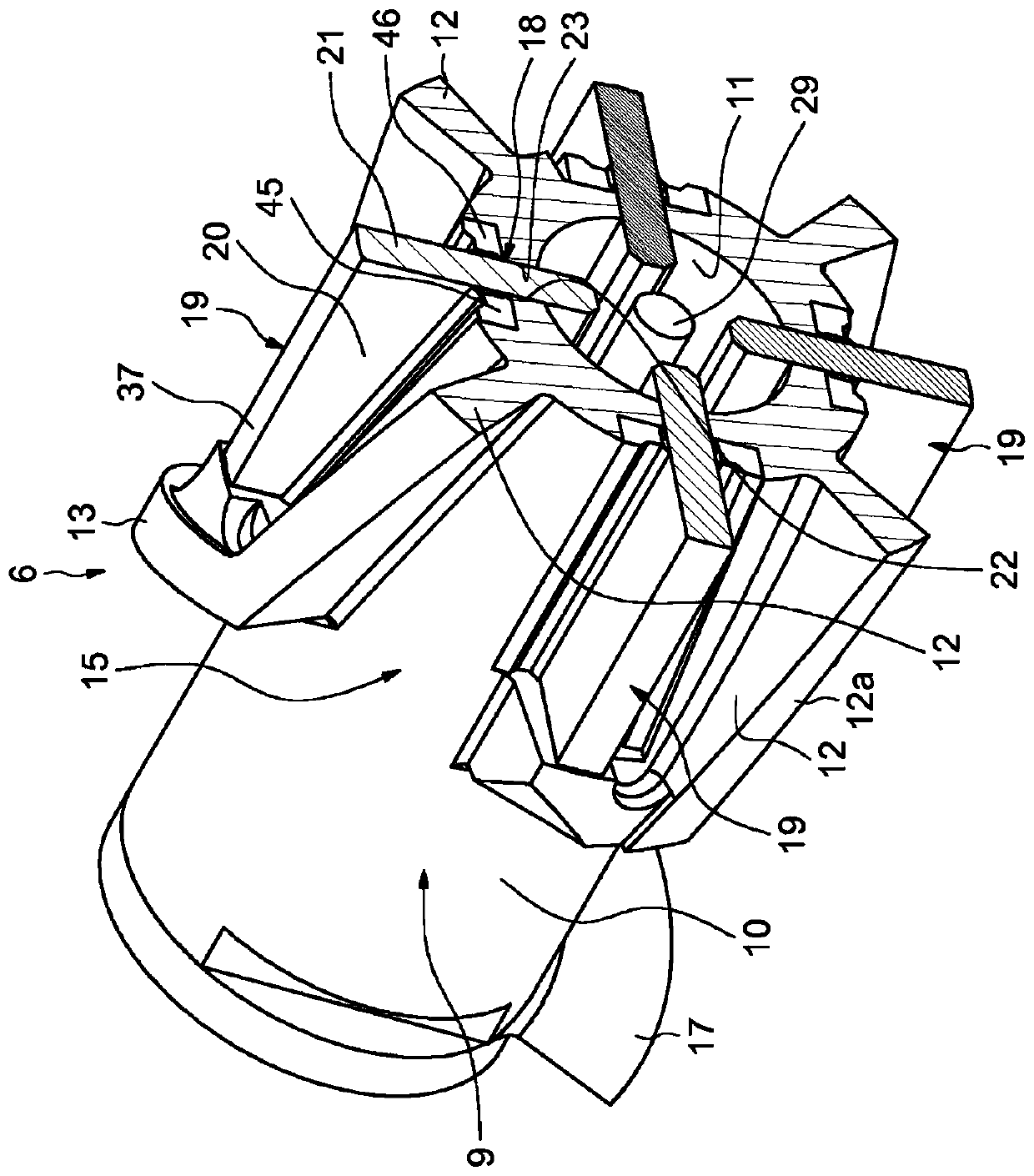

[0029] figure 1 The extruder 1 is partially shown, which includes a longitudinal sheath 2 having a channel 3 with a longitudinal axis, the channel 3 being, for example, cylindrical and extending in a downstream direction. The rotating longitudinal component 4 is installed in the longitudinal channel 3 for driving the material to be extruded in the downstream direction.

[0030] The extruder 1 includes a geared motor (not shown) located upstream for driving the rotating longitudinal assembly 4, an extrusion die (not shown) located downstream of the torpedo head 6 and used to introduce the material to be extruded into Mechanism in longitudinal channel 3 (not shown).

[0031] The rotating longitudinal assembly 4 includes an upstream longitudinal screw 5 and a downstream longitudinal torpedo head 6, the upstream end of the torpedo head 6 is mounted on the downstream end of the screw 5 by a fixing mechanism (not shown). The screw 5 extends in the upstream portion 3a of the longitudinal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com