Torpedo pipeline maintenance equipment

A maintenance and pipeline technology, applied in the direction of mechanical equipment, offensive equipment, torpedo launchers, etc., can solve the problems of poor practicability, inconvenient disassembly and replacement, and large volume, and achieve compact size, easy disassembly and replacement, and complete functions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

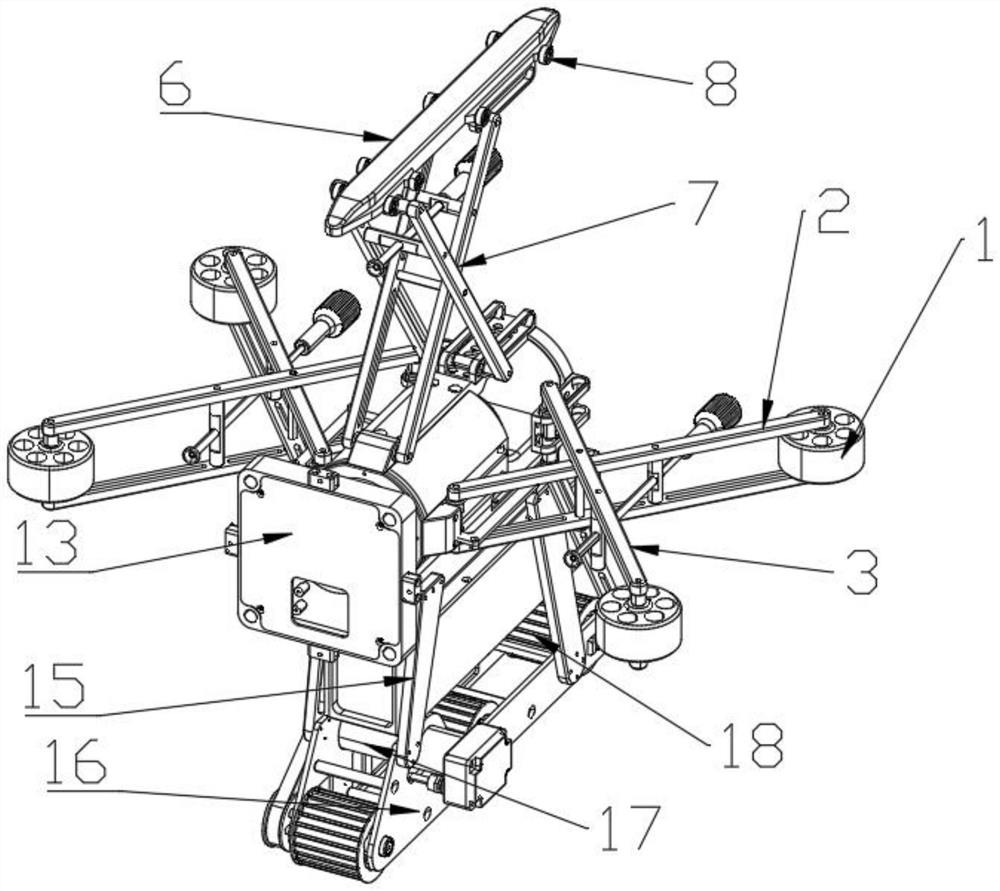

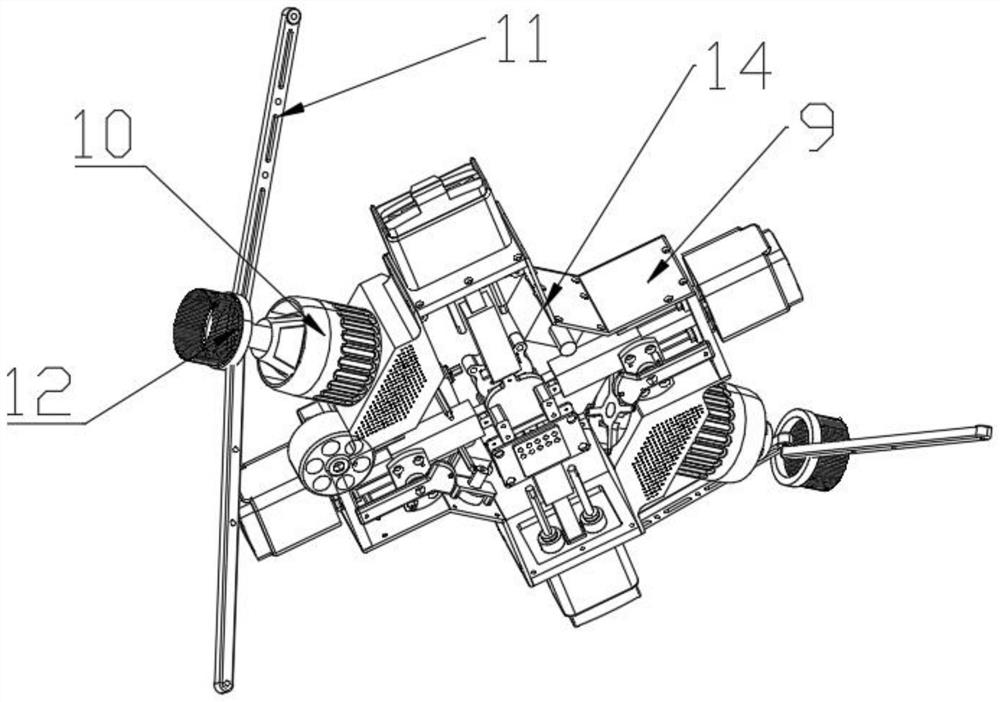

[0030]A torpedo pipeline maintenance equipment, including a carrying device that can walk along the inside of the pipeline autonomously, a support mechanism that is adjustable on the carrying device and supports it, and is designed separately from the carrying device and provides cleaning or oiling for it. A functional module with functions of water absorption or rust removal, and a quick-change device for quickly disassembling and connecting the functional module and the carrying equipment, the functional module is located at the end of the carrying equipment, and the overall structure diagram of the present invention is as follows: figure 1 shown.

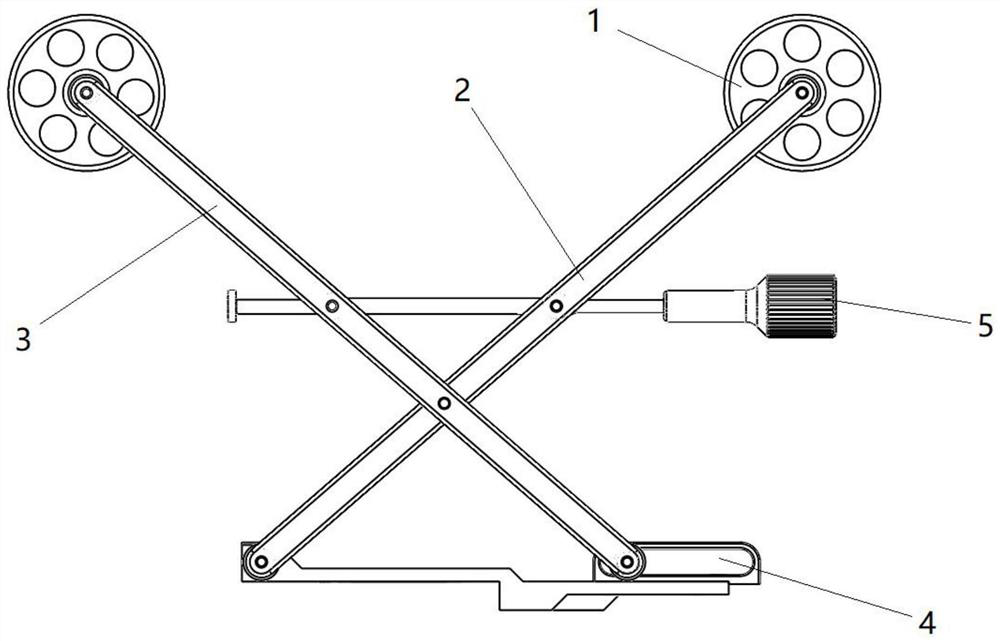

[0031] The support mechanism includes a support bracket and a support wheel 1. The support bracket is composed of a support fixed rod 2 whose one end is rotatably connected with the carrying equipment and a supporting moving rod 3 whose one end is slidably connected with the carrying equipment through a chute 4. The supporting fix...

Embodiment 2

[0041] The functional module in the first embodiment is replaced with an oiling module for evenly applying lubricating grease on the guide rails in the pipeline. The oiling module includes an oiling frame 22, an oiling pump 23 for automatic oil pumping, a telescopic function The telescopic rod 24 and the flexible end 25 for applying lubricating grease to the guide rails, the oiling frame 22 is arranged at the end of the mounting equipment through the quick change device, the oiling pump 23 is arranged on the oiling frame 22 and is fixedly connected with the oiling frame 22, the telescopic rod 24 The inner track of the corresponding pipeline is arranged around the oiling frame 22, the flexible end 25 is arranged on the end of the telescopic rod 24 away from the oiling frame 22 and is fixedly connected with the telescopic rod 24, and the flexible end 25 is communicated with the oiling pump 23 through the oil pipe. The oil module cooperates with the oiling frame 22 , the oiling pu...

Embodiment 3

[0046]The functional module in the first embodiment is replaced with a water absorbing module for absorbing water in a designated area in the pipeline. The water absorbing module includes a water absorbing frame 26, a telescopic arm 27 with telescopic function and a water suction head for absorbing water in the designated area inside the pipeline. 28. The water-absorbing frame 26 is arranged at the end of the carrying equipment through the quick-change device, the water-absorbing frame 26 is clamped with the quick-changing device, the telescopic arms 27 are arranged on both ends of the water-absorbing frame 26 and are fixedly connected with the water-absorbing frame 26, and the water-absorbing head 28 is arranged at the The telescopic arm 27 is away from the end of the water absorption frame 26 and is fixedly connected with the telescopic arm 27. The water absorption module cooperates with the water absorption frame 26, the telescopic arm 27 and the water suction head 28 to perf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com