Torpedo ladle lining smearing repair material, preparation method and use method

A technology of torpedo tanks and repairing materials, which is applied in the direction of manufacturing tools, casting equipment, metal processing equipment, etc., can solve the problems of long baking time of torpedo tanks, reduce the amount of dismantling, digging, repairing and repairing, and coating melting loss, etc., and improve the performance of torpedoes. The thermal insulation performance of tank refractory lining, the reduction of consumption and maintenance costs, and the effect of reducing the temperature drop of molten iron

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

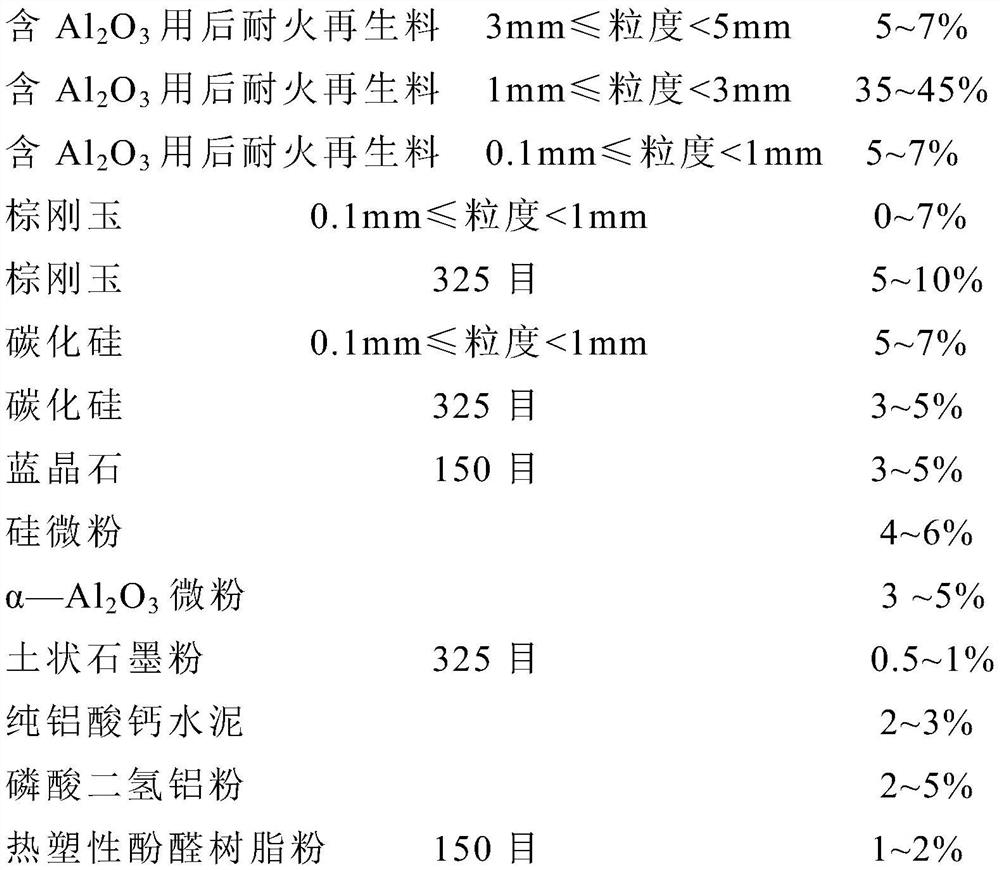

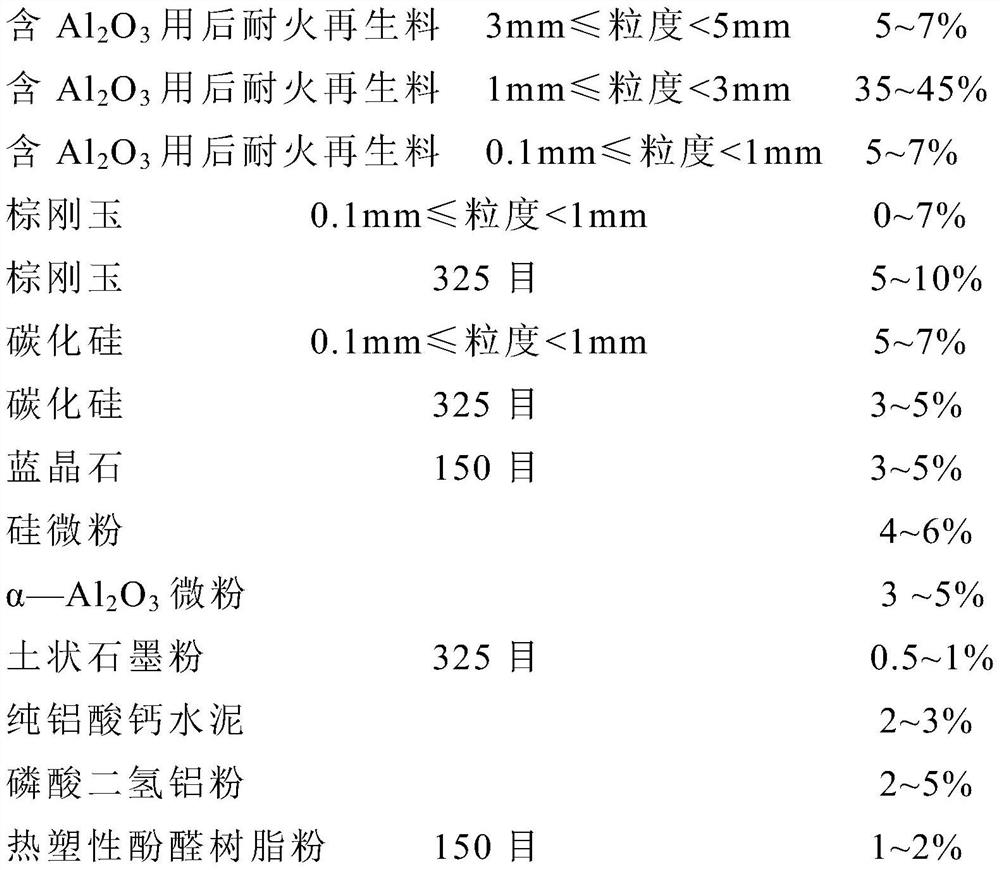

[0037] The torpedo tank lining smear repair material includes main raw materials and auxiliary raw materials, and the main raw materials include by weight percentage:

[0038]

[0039] Auxiliary raw materials include metal silicon powder (200 mesh), oxalic acid, polypropylene and polyethylene fiber mixture (weight ratio is 1:1), sodium tripolyphosphate and sodium hexametaphosphate mixture (weight ratio is 1:1 ), the weight of metal silicon powder accounts for 0.5-1.5% of the total weight of the main raw materials, the weight of oxalic acid or tartaric acid accounts for 0-1.5% of the total weight of the main raw materials, and the weight of polypropylene and polyethylene fiber mixture accounts for 0.05-0.15% of the total weight of the main raw materials , the weight of the mixture of sodium tripolyphosphate and sodium hexametaphosphate accounts for 0.1-0.25% of the total weight of the main raw materials, and the total carbon content of the repair material is 3-6%;

[0040] A...

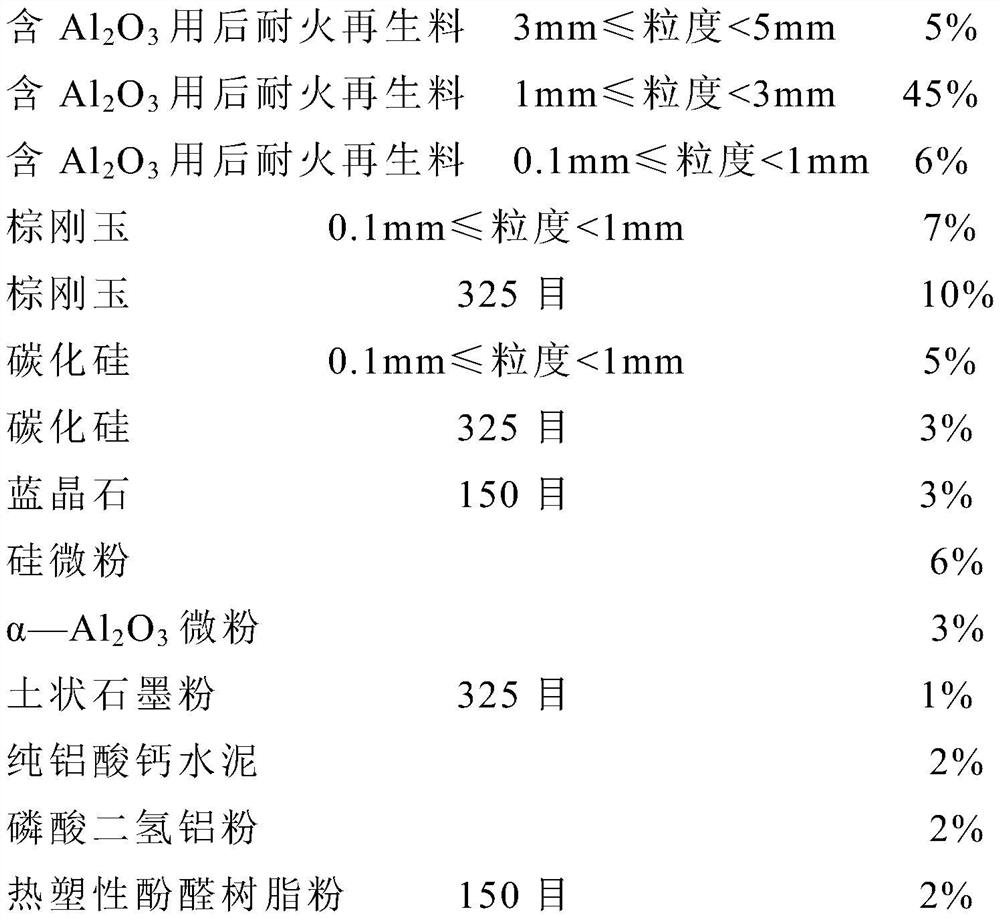

Embodiment 2

[0054] Three different particle sizes containing Al 2 o 3 The surface of the used refractory regenerated material is covered with nano-carbon film, and the surface of two kinds of brown corundum with different particle sizes is covered with nano-carbon film. It is the same as that of Embodiment 1 and will not be repeated here.

[0055] According to each component in embodiment 1, embodiment 2, the torpedo tank liner smear repair material containing nano-carbon film carbon source prepared by mass percentage, compared with conventional torpedo tank liner carbon-containing repair material, bulk density improves 3 ~5%, the flexural strength increased by 5-10% after heat treatment at normal temperature and different temperatures, the number of thermal shock resistance by water cooling at 1100°C increased by more than 20%, and the anti-slag and anti-oxidation experiments at 1450°C for 3 hours in an oxidizing atmosphere showed that the erosion and penetration of slag was not obvious...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com