Automatic oiling device for inner side guide rail of special pipeline

A technology of oiling device and guide rail, which is applied to the device and coating of the surface coating liquid, which can solve the problem that maintenance equipment cannot fully meet the maintenance requirements of submarine torpedo launching pipelines, and the guide rail oiling work cannot be completed accurately and efficiently , complex structure and other issues, to achieve the effect of improving quality and efficiency, realizing lateral limit, and simple setting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

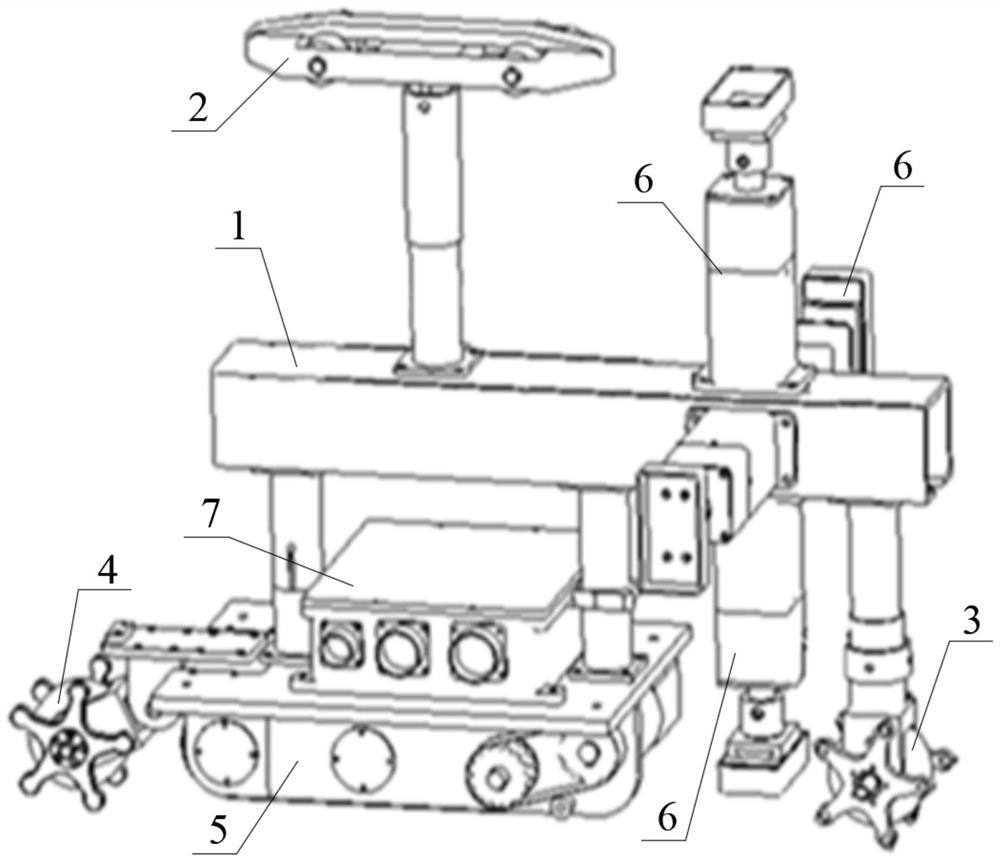

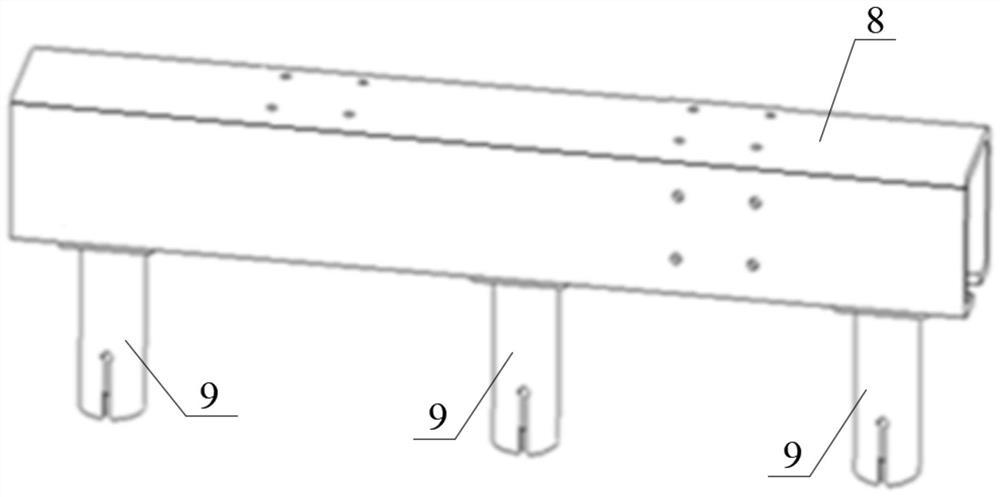

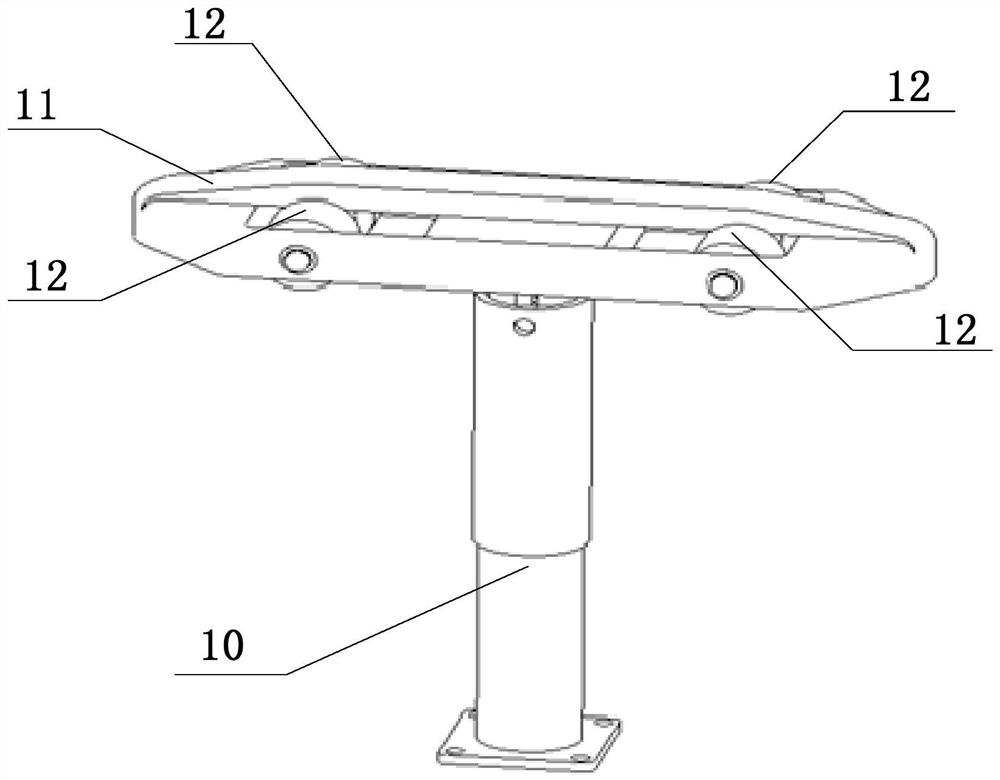

[0047] see Figure 1-8 , the special pipe inner rail automatic oiling device in the preferred embodiment of the present invention includes a support frame 1, a traveling mechanism 5, an oiling assembly and a control mechanism 7. Among them, the support frame 1 is set on the running gear 5, and can reciprocate under the drive of the running gear 5; secondly, the oiling assembly is set on the support frame 1, and the pipeline can be realized while the running gear 5 moves in the pipeline. The oiling process of each guide rail in the torpedo launch pipeline; again, the control mechanism 7 is set corresponding to the running gear 5, and is used to control the running gear 5 to carry out the corresponding movement process, thereby accurately completing the oiling maintenance work of the guide rails in the torpedo launching pipeline.

[0048] In order to accurately express the setting form of the corresponding structure on the automatic oiling device and the operating form of the au...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com