Ultra-low clearance vehicle-mounted uncovering machine above torpedo ladle opening

A technology for torpedo cans and capping machines, which is applied to casting molten material containers, metal processing equipment, casting equipment, etc., can solve the problems of low clearance tolerance, too long cantilever, and inability to open the cover, so as to reduce environmental pollution, reduce environmental pollution, and reduce environmental pollution. The effect of stable and reliable structure and reduced consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

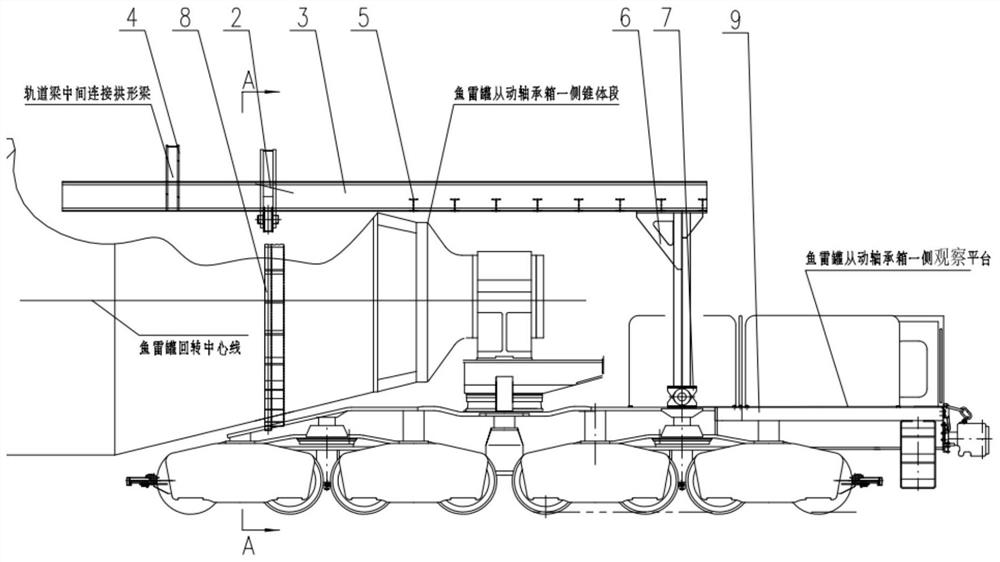

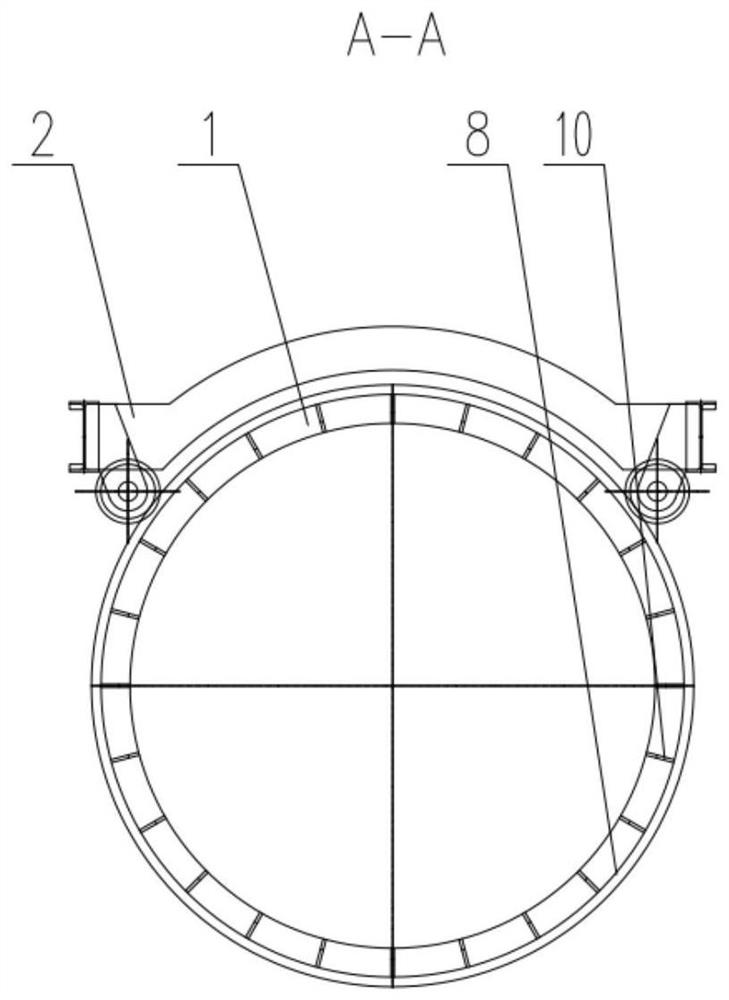

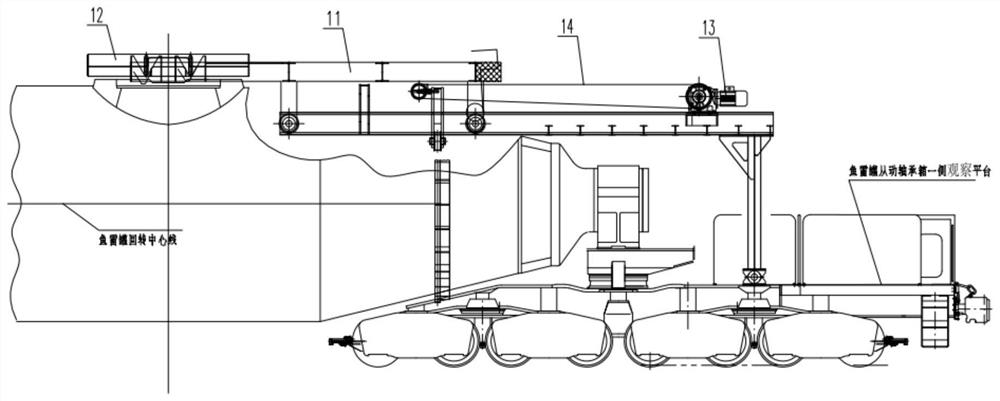

[0027] Figure 1 to Figure 8 It is a specific embodiment of the present invention.

[0028] The flat car track of the present invention realizes several functions, one is to transfer the vertical load of the capping machine to the tank body through the ring track 1 and the transition leg 10 through the bow-shaped floating column foot 2 with casters, also known as the floating fulcrum, to share, and The uncapping machine and tank cover 12 are symmetrically designed relative to the center plane of rotation, and the center of gravity is always within the range of the center plane of rotation, that is, in the middle of the railway transportation line; When the annular track 1 rotates relatively, the self-aligning state of the flat car track can be maintained, which also benefits from the horizontal fixed relationship between the hinged seat 7 of the flat car track and the artificial observation platform; the third is that the design of the torpedo tank itself is a self-weight alig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com