Slag-blocking system for torpedo ladles

A torpedo and slag baffle technology, which is applied to casting molten material containers, mechanical cleaning, manufacturing tools, etc., can solve problems such as iron slag, achieve good effect, easy operation, and improve the qualified rate of steelmaking products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

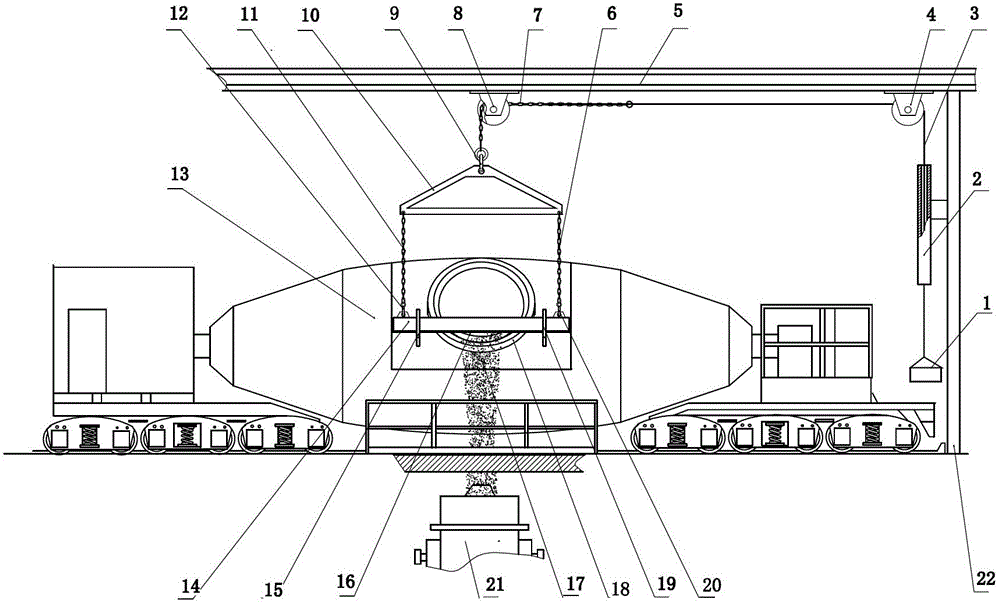

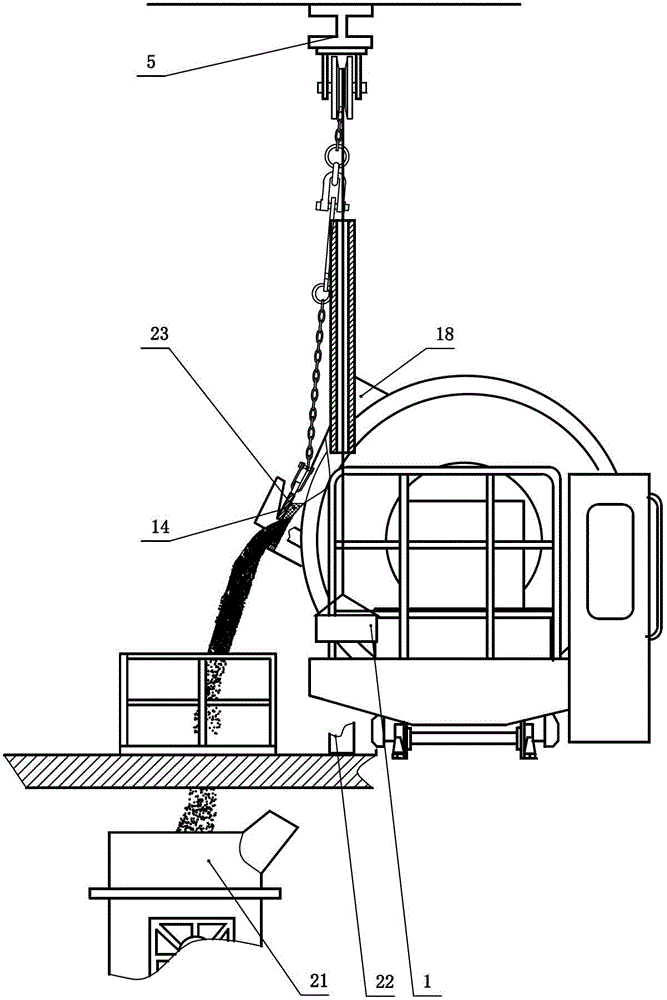

[0013] Such as figure 1 , 2 As shown, it includes: a counterweight (1), one end of the counterweight (1) connected to the wire rope (3), and the other end of the wire rope (3) passes through the guide tube (2) fixed on the support column (22), Go through the guide fixed pulley (4) and then connect one end of the suspension chain (7), and the other end of the suspension chain (7) passes through the fixed pulley (8) and then connects the suspension U-shaped card (9); the guide fixed pulley (4), the fixed pulley (8) are all fixed on the I-shaped beam (5); the balance frame (10) is connected below the hanging U-shaped card (9), and the right end of the balance frame (10) is connected with the right chain (6) and connect the right side of the slag retaining plate (14) through the right U-shaped card (20); the left side of the balance frame (10) is connected with the left chain (11) and through the left U-shaped card (12) Connect the left side of the slag retaining plate (14); t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com