Torpedo anchor capable of increasing anchoring length

An anchoring length and torpedo technology, applied in anchor points, ship parts, transportation and packaging, etc., can solve the problem that the bearing capacity cannot meet the design requirements, and it is difficult to reach the specified soil layer, so as to meet the requirements of the anti-pull performance and improve the stability. , the effect of high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

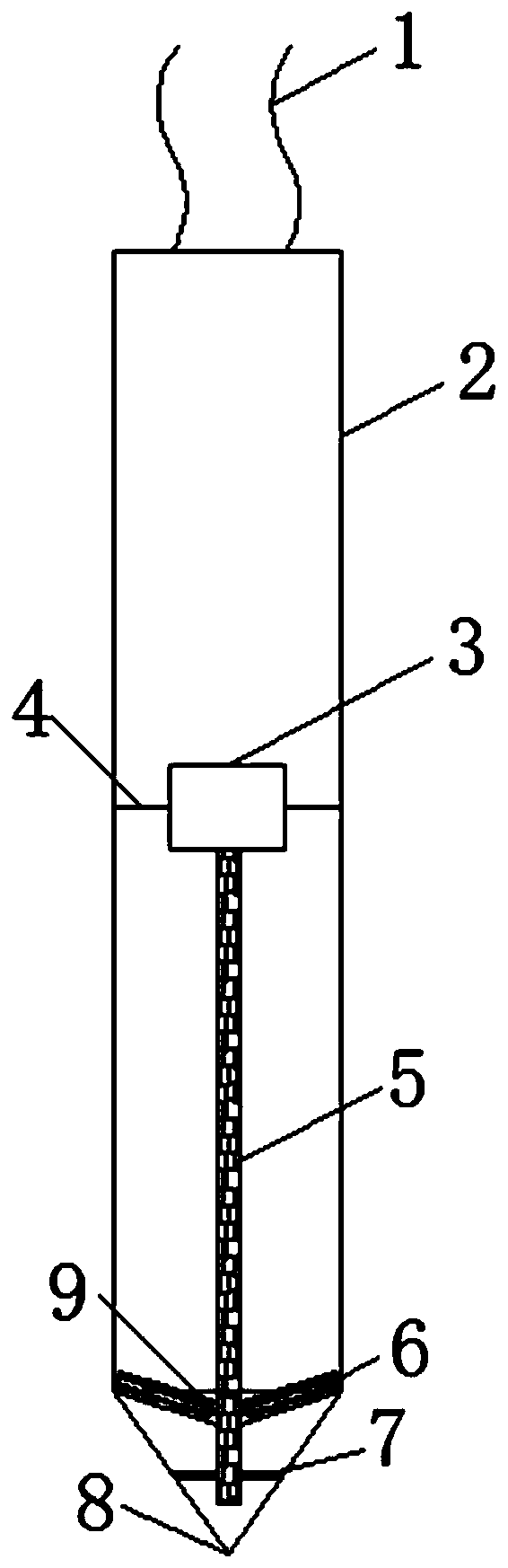

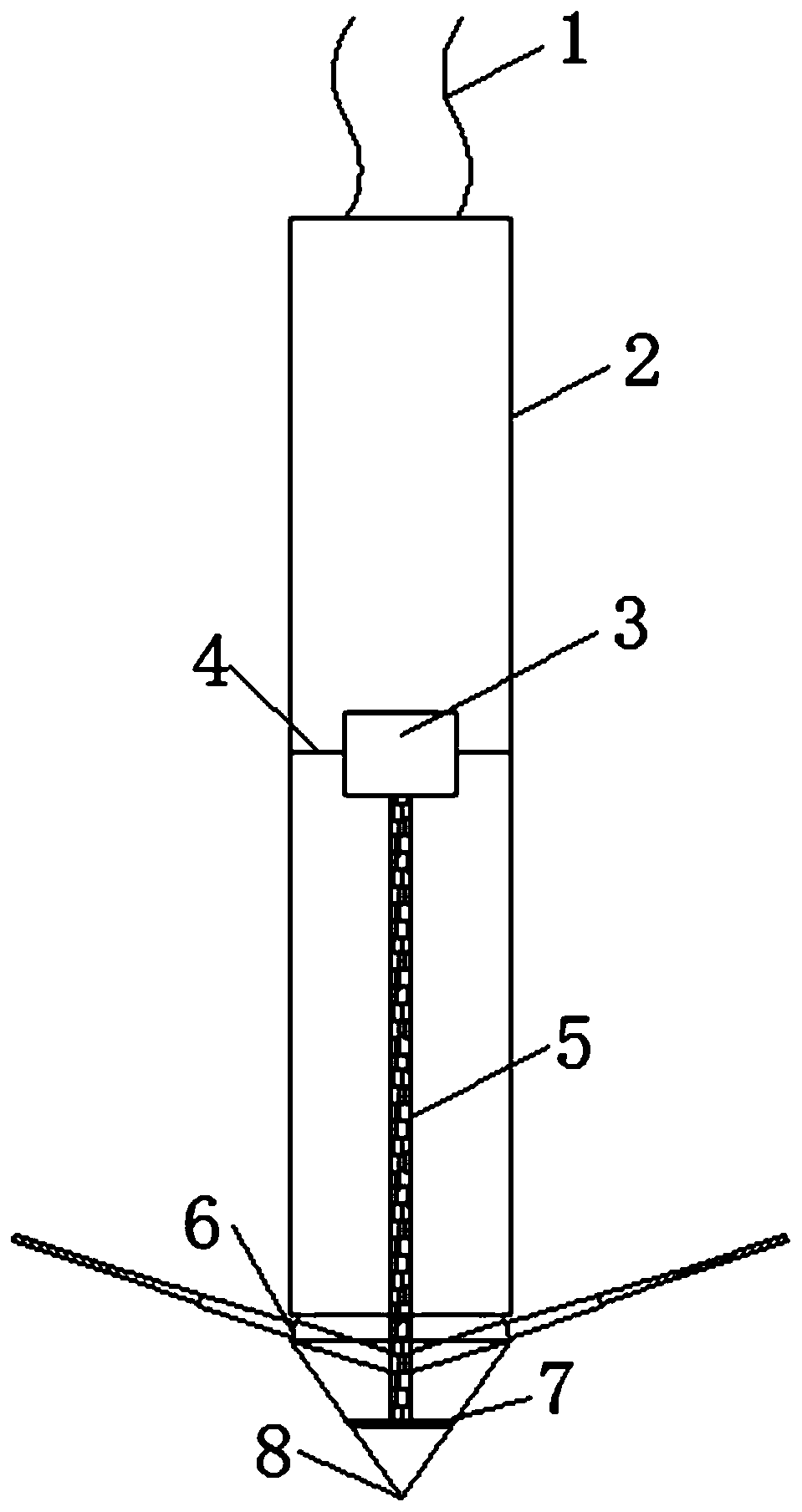

[0036] like figure 2 As shown, when the anchor head 8 encounters a hard soil layer and reaches the specified depth, the motor 3 rotates to drive the anchor head 8 to separate from the anchor body 2, and the rotating blade 6 is in free contact with the anchor body 2 and the anchor head 8. When reaching a certain distance from the anchor body 2, due to the loss of support, the spring 9 preloaded inside will eject the blade section, and make the groove block 11 snap into the corresponding groove 12, and complete the extension of the rotary blade 6. Driven by the motor 3, the rotary blade 6 starts to rotate and cut the soil layer, so that the torpedo anchor is continuously lowered and finally reaches the designated depth.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com