Method for determining illumination intensity distribution of light source and mask pattern of photo-etching process

A technology of light intensity and photolithography technology, which is applied in the field of integrated circuit manufacturing, can solve the problems of long calculation time and unsatisfactory effect, and achieve the effects of shortened calculation time, good effect and good optimization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

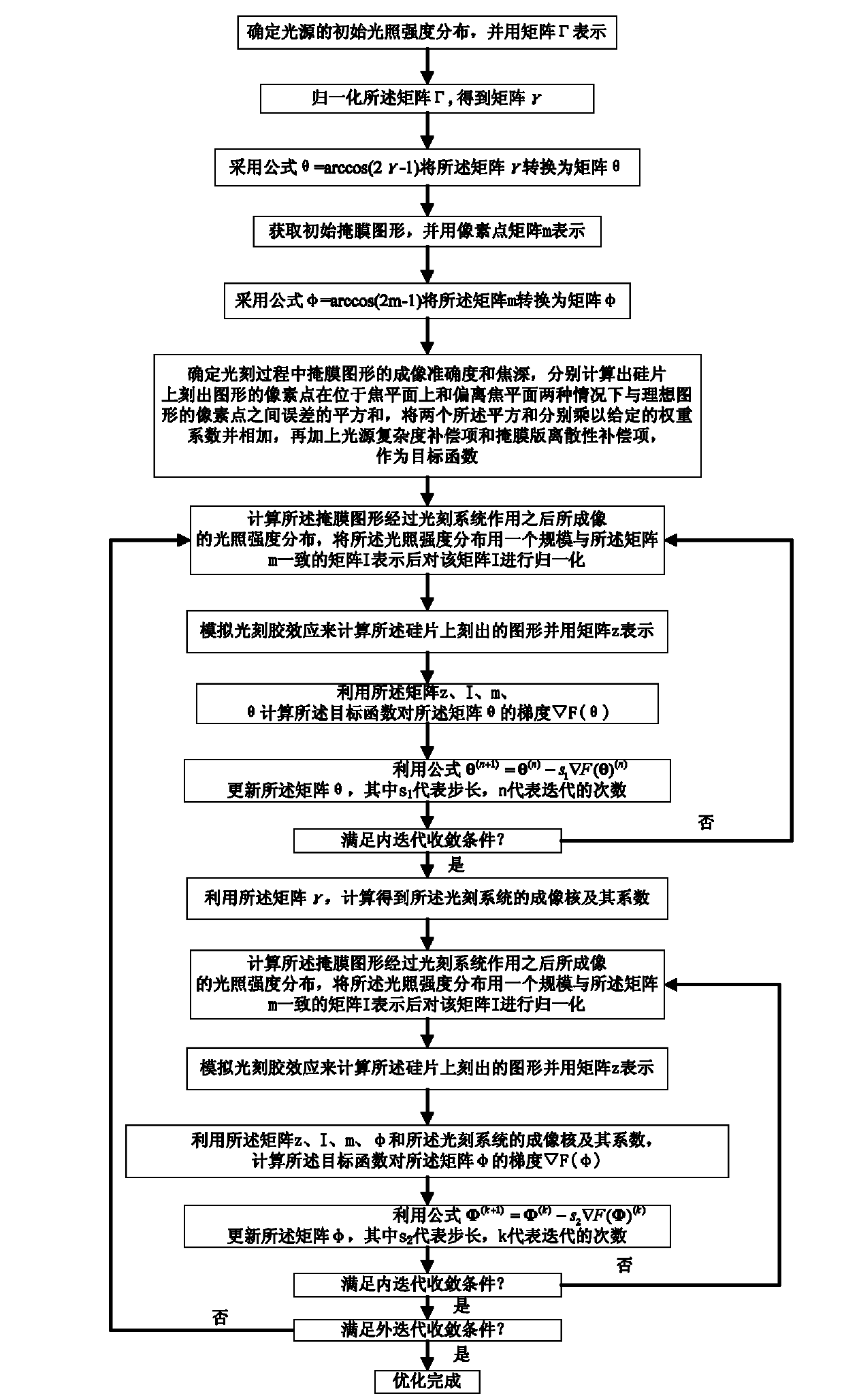

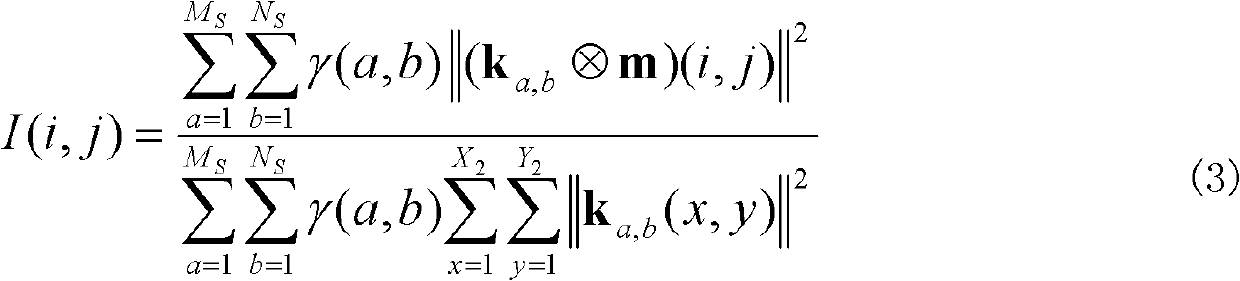

[0047] figure 1 It is a flow chart of the method for optimizing the light source of the photolithography process according to the present invention. Such as figure 1 As shown, the method for determining the illumination intensity distribution of the photolithography process light source of the present invention comprises the following steps:

[0048] (1) Use matrix Γ to represent the initial illumination intensity distribution of the determined light source;

[0049] According to the traditional light sources used in the photolithography process in the current integrated circuit manufacturing, such as circular and ring-shaped light sources, determine the initial light intensity distribution of a light source, and use a matrix Γ to represent the light source, and each element in the matrix Γ is respectively Corresponding to a pixel at the correspondi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com