Timing sequence plan automatic making system for steelmaking workshop

A planning and timing technology, applied in computing, data processing applications, forecasting, etc., can solve problems such as unparalleled superiority and the need to improve search efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

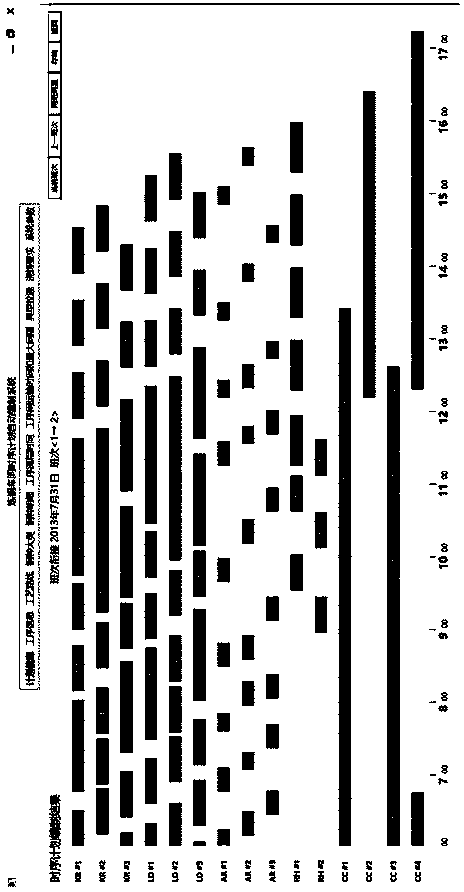

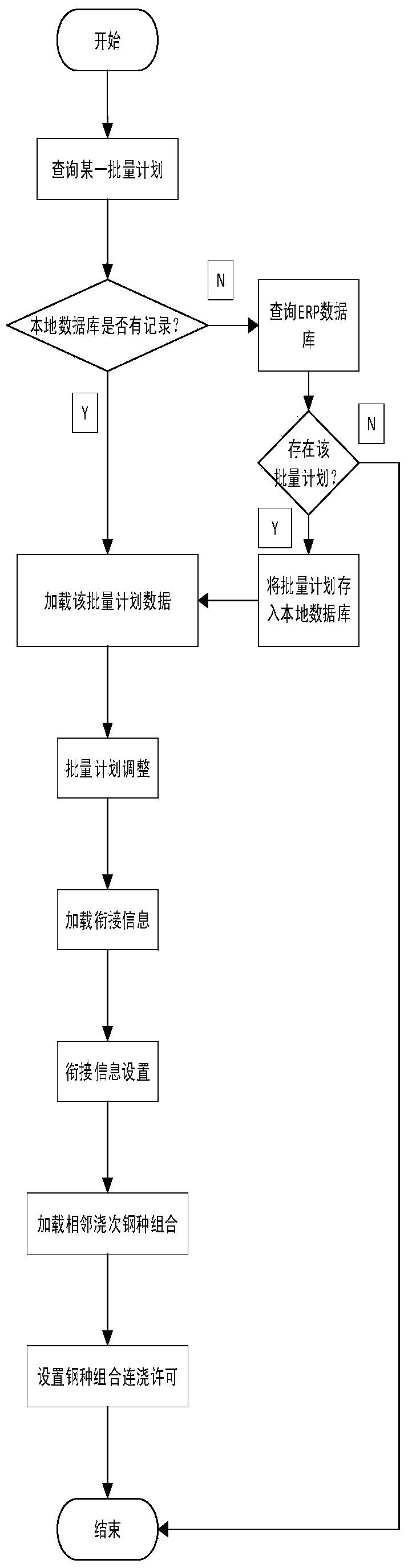

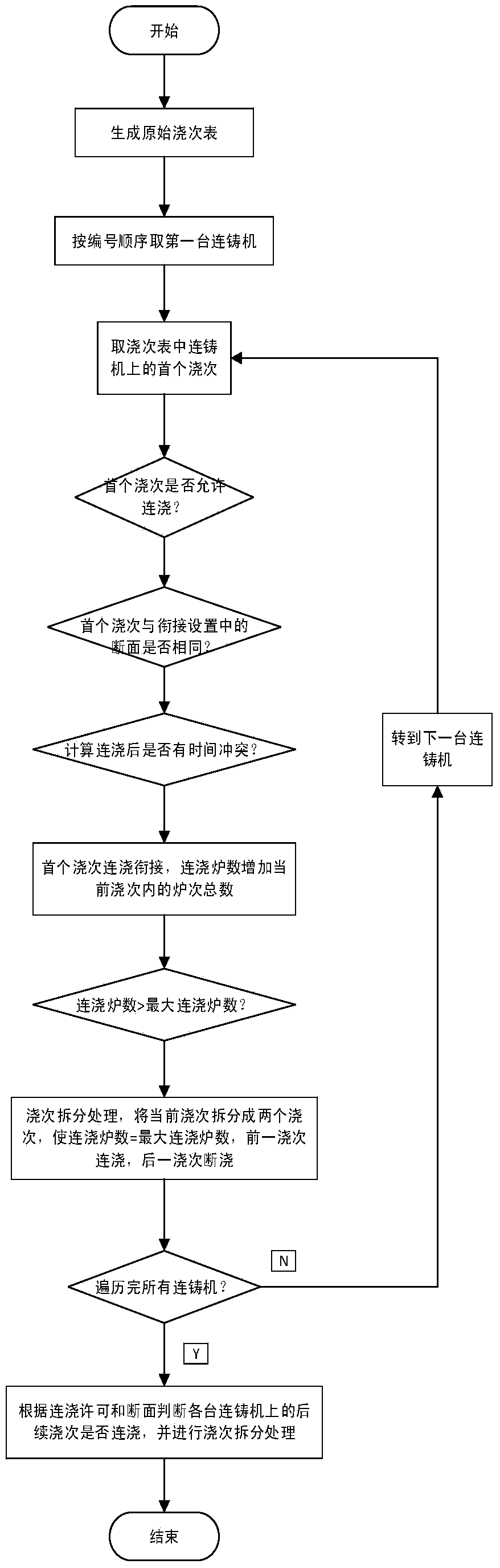

[0079] The present invention is an automatic preparation system of steelmaking workshop time series plan based on the ERP platform of the steel enterprise. The system downloads the steelmaking batch plan data from the ERP platform of the steel enterprise, saves it in the independent database of the system itself, and can perform the original data Operation and maintenance ensure the relative independence of the system and the ERP platform. The hardware configuration required by the system is a personal computer (a computer with a multi-core processor is recommended) and a computer network (a modem required for an Ethernet card or dial-up network). The system software includes the Microsoft SQL Server 2005 database, the interface with the steel enterprise ERP platform, the front-end UI interface, the data preprocessing module and the parallel hybrid intelligent algorithm based on the steel-making workshop's timing planning model. The software of the present invention includes th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com