Plug seedling tray transplanting production line and use method thereof

A production line and hole seedling technology, which is applied in the field of hole seedling tray transplanting production line, can solve the problems of reducing transplanting efficiency, clamping error, seedling damage, etc., to improve transplanting efficiency, increase the number of trays and seedlings, and improve automation Effects of Degree and Work Effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

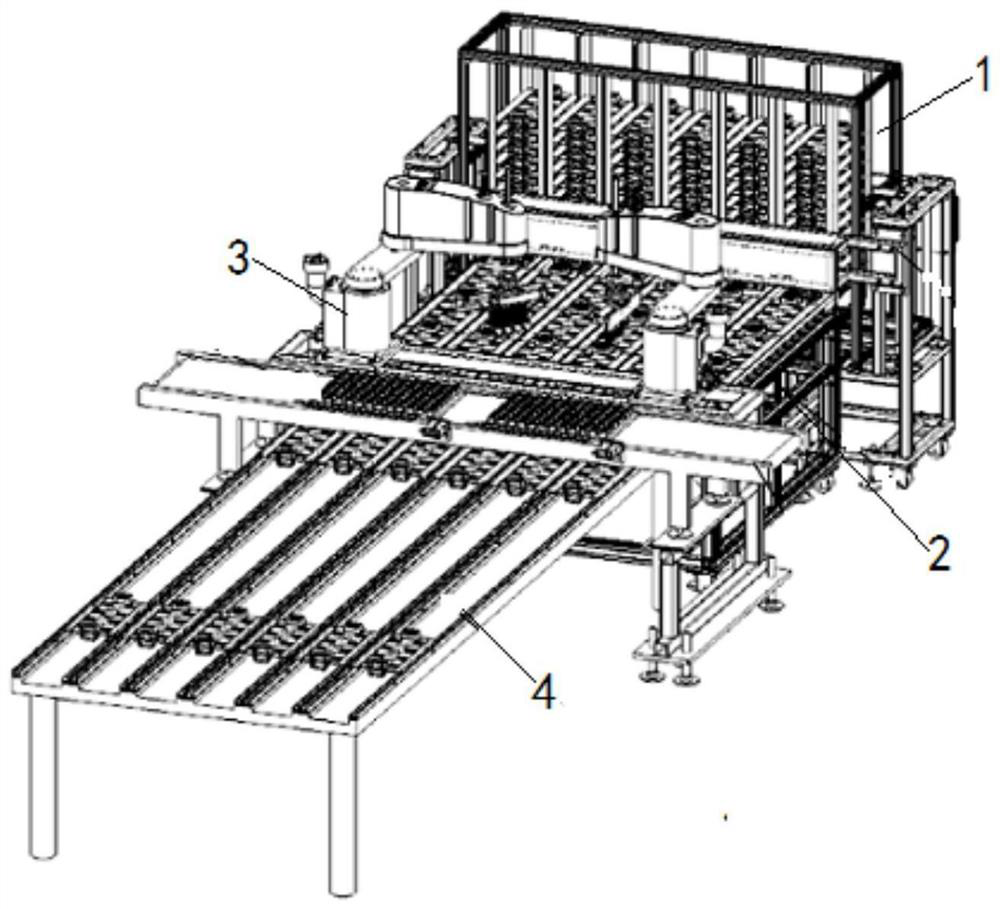

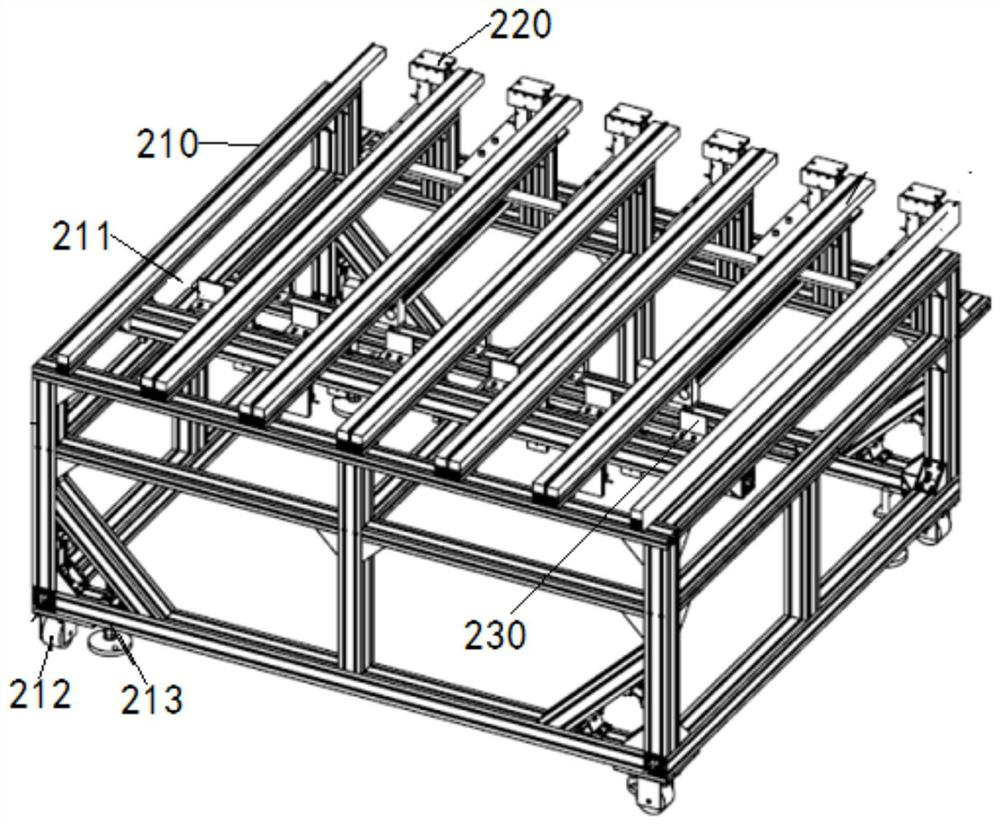

[0036] Embodiment 1: A production line for seedling tray transplanting, including a tray storehouse, a transfer table, a transplanting machine and a cultivation platform connected in sequence.

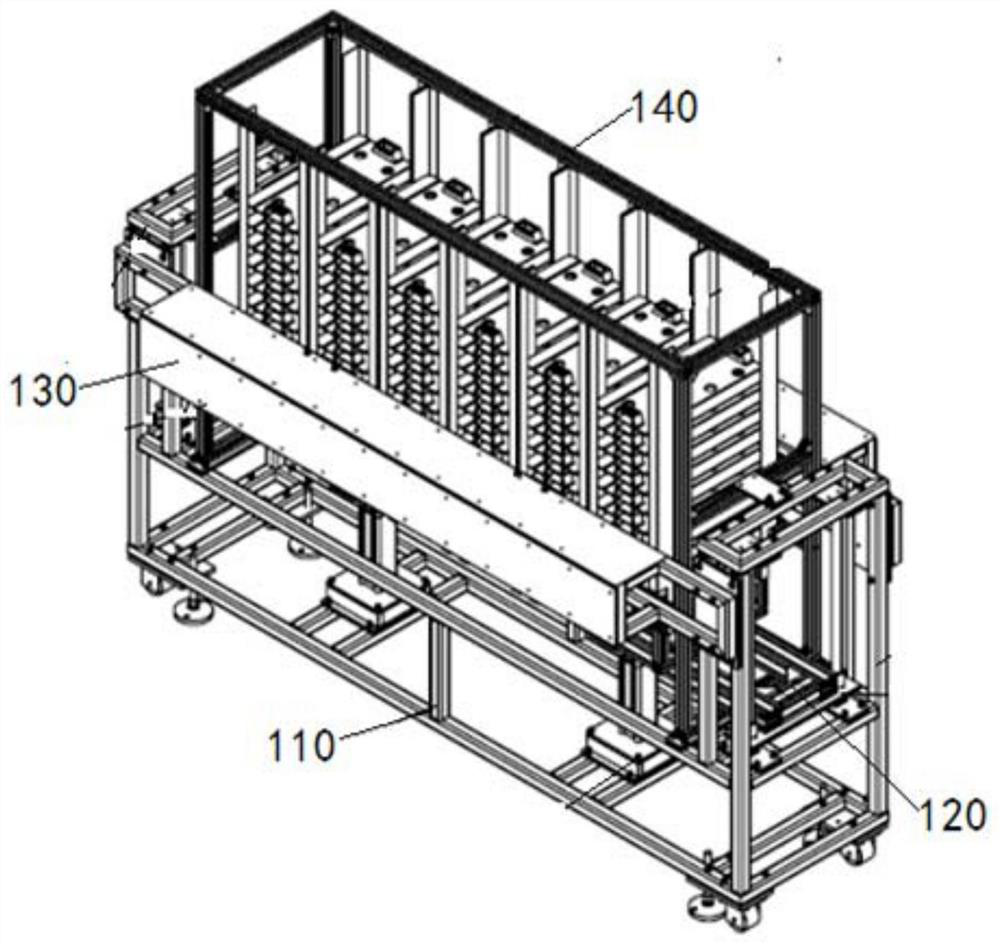

[0037] The pallet warehouse includes a pallet warehouse rack, on which a pallet device, a separation device and a pallet storage rack are installed.

[0038] The tray device includes a bracket and a bracket lifting mechanism; the bracket is installed on the rack of the tray library, and a plurality of tray support grooves are arranged on it along the length direction of the rack of the tray library; the bracket lifting mechanism is installed on the tray below the bracket On the library rack, it is used to control the lifting of the bracket;

[0039] The separation device includes a fork installation frame installed on the rack of the pallet warehouse, and a fork mechanism is installed on the fork installation frame; the fork mechanism includes a fork, a slide block I, a slide rail I an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com