Manufacturing method of nano-channel with gradually-changed size

A technology of nano-channel and manufacturing method, applied in the field of nano-channel manufacturing, to achieve the effects of expanding the application range, facilitating biochemical analysis, and avoiding channel blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

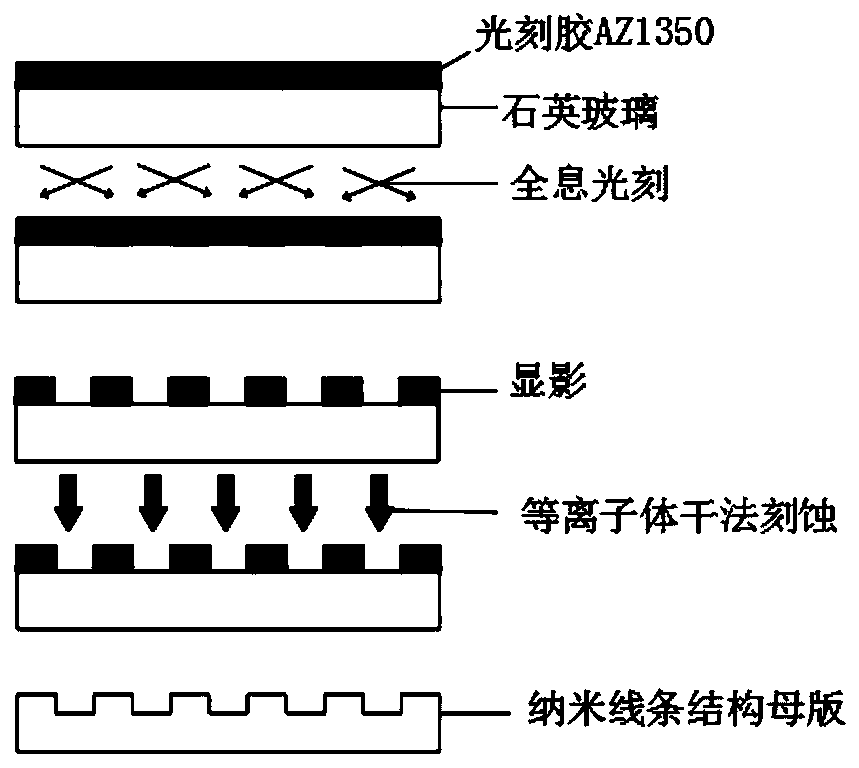

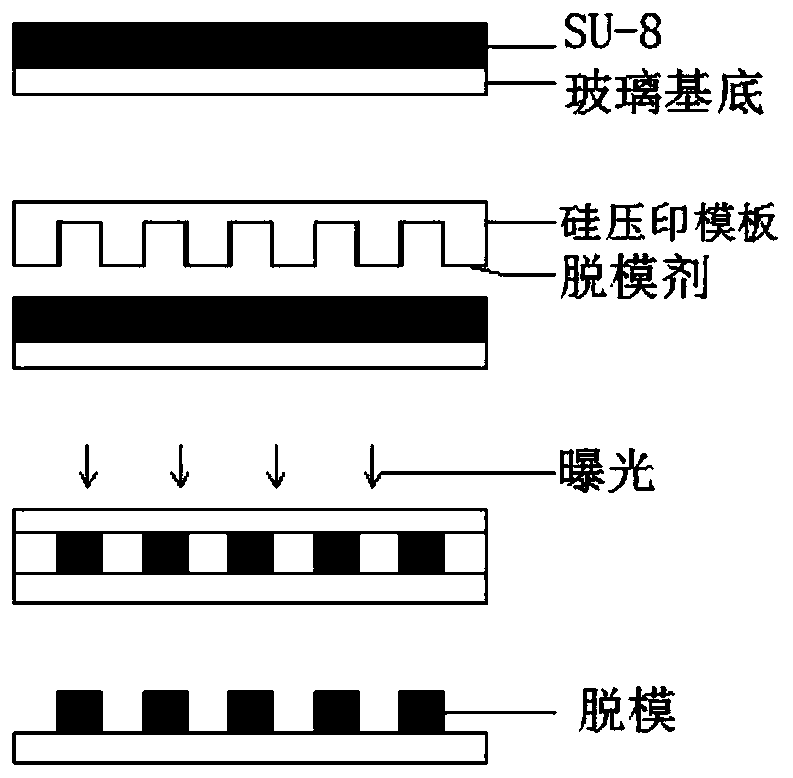

[0041] This embodiment provides a method for fabricating nanochannels with graded sizes, comprising the following steps:

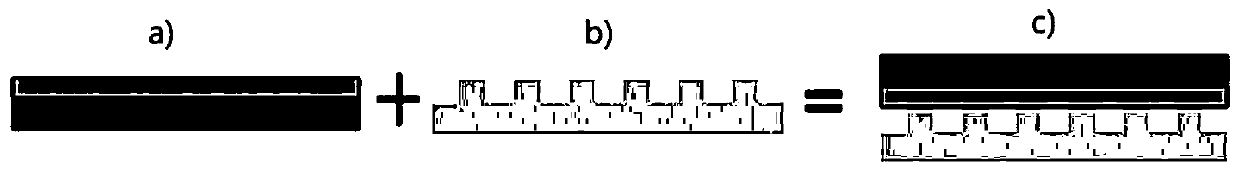

[0042] Step 1, the making of nanowire structure template; its making process is as follows figure 2 shown.

[0043] Step 1.1, take a piece of quartz glass with high light transmittance and flat surface as the substrate, wash the quartz glass with water and acetone, put it in an oven, and bake it at 130°C for 10 minutes to remove water vapor and residual acetone. After natural cooling, put it into an asher and incinerate for one hour to enhance its surface adhesion. Then apply a layer of tackifier (AZAD PROMOTER tackifier) on the surface of the quartz through a glue leveler to increase the viscosity of the substrate and prevent the debonding of the photoresist during development. The speed of the homogenizer is 1500r / min, the time is 30s, and placed in an oven at 90°C for 10 minutes;

[0044]Step 1.2, after pre-processing the quartz substrate, coat it...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Etching depth | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com