Knitting MES production planning and scheduling method based on big data mining

A technology of production planning and scheduling method, applied in the direction of control/adjustment system, comprehensive factory control, instrument, etc., can solve problems such as frequent product changes, untimely order scheduling, and unclear division of responsibilities, so as to improve the competitiveness of enterprises and The degree of refined management, the improvement of comprehensive utilization of equipment, and the effect of reducing the time for information transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

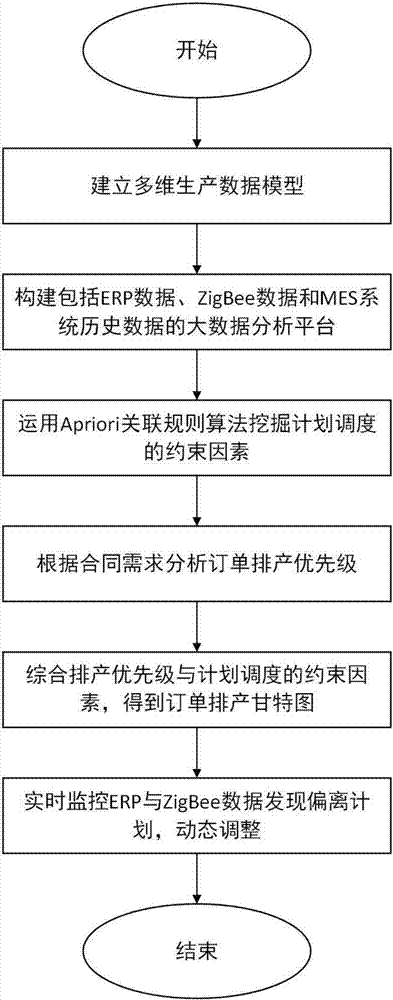

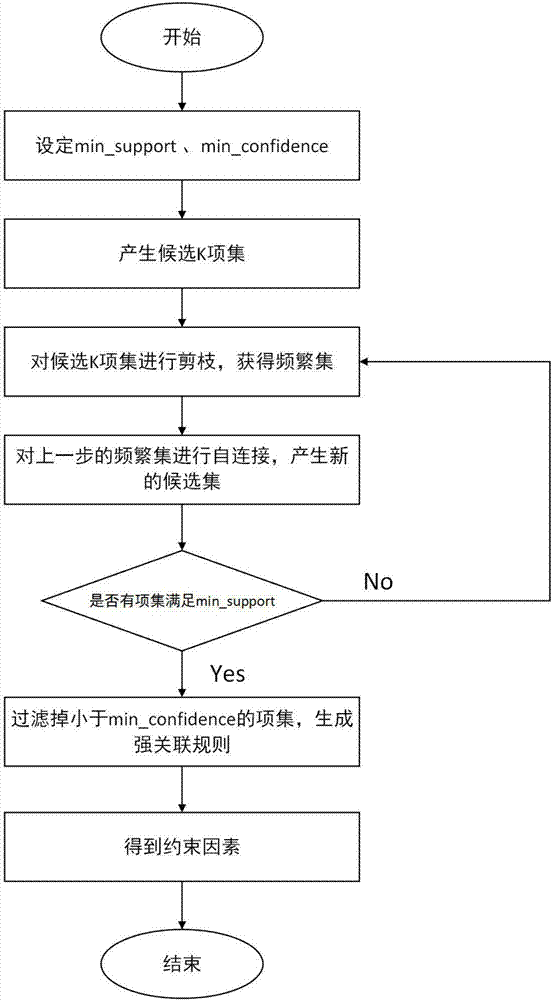

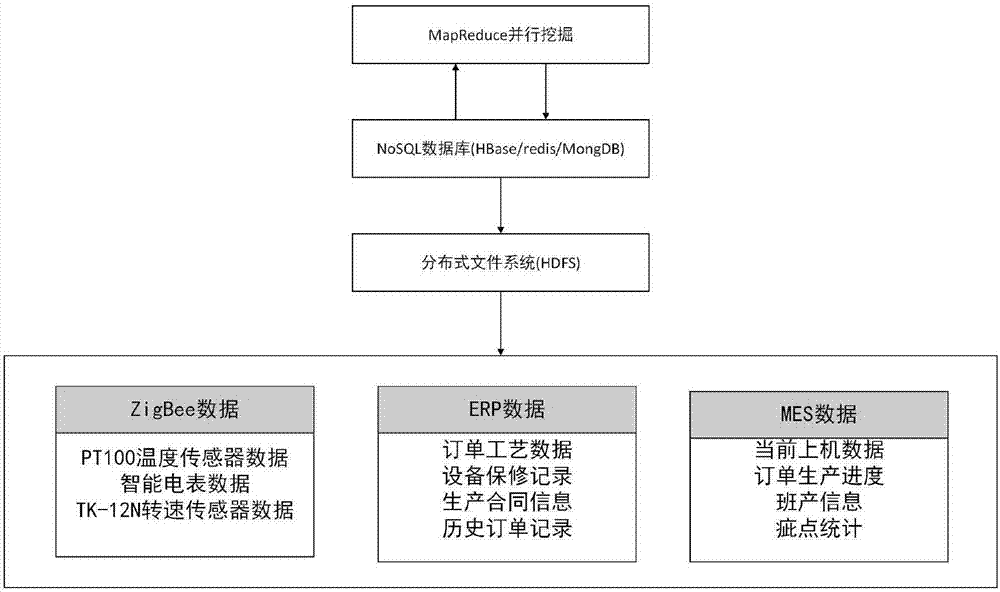

[0042] figure 1 The knitting MES production planning and scheduling method based on big data mining shown in , its specific steps include S1, establishing a multi-dimensional knitting production data model (including multi-dimensional knitting data acquisition technology and communication protocol); S2, building a distributed platform based on Hadoop includes A big data analysis platform for ERP data, ZigBee data, and MES system historical data; S3, use the Apriori association rule mining algorithm to mine the constraints of planning and scheduling under the MapReduce framework, and obtain the resource constraints, process constraints, and production constraints of the corresponding orders. Quality constraints and planning time constraints; S4. Analyze the priority of order scheduling according to contract requirements; S5. Comprehensive scheduling priority and constraints of plan scheduling to obtain the Gantt chart of order scheduling; S6. Real-time monitoring of ERP and ZigB...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com