Hybrid intelligent scheduling optimization method of manufacturing enterprise workshop

A technology of intelligent scheduling and optimization methods, applied in manufacturing computing systems, data processing applications, forecasting, etc., can solve problems that consume a lot of time, a lot of storage space, and high hardware requirements, and achieve shorter time consumption, higher computing speed, and better search solutions. large space effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

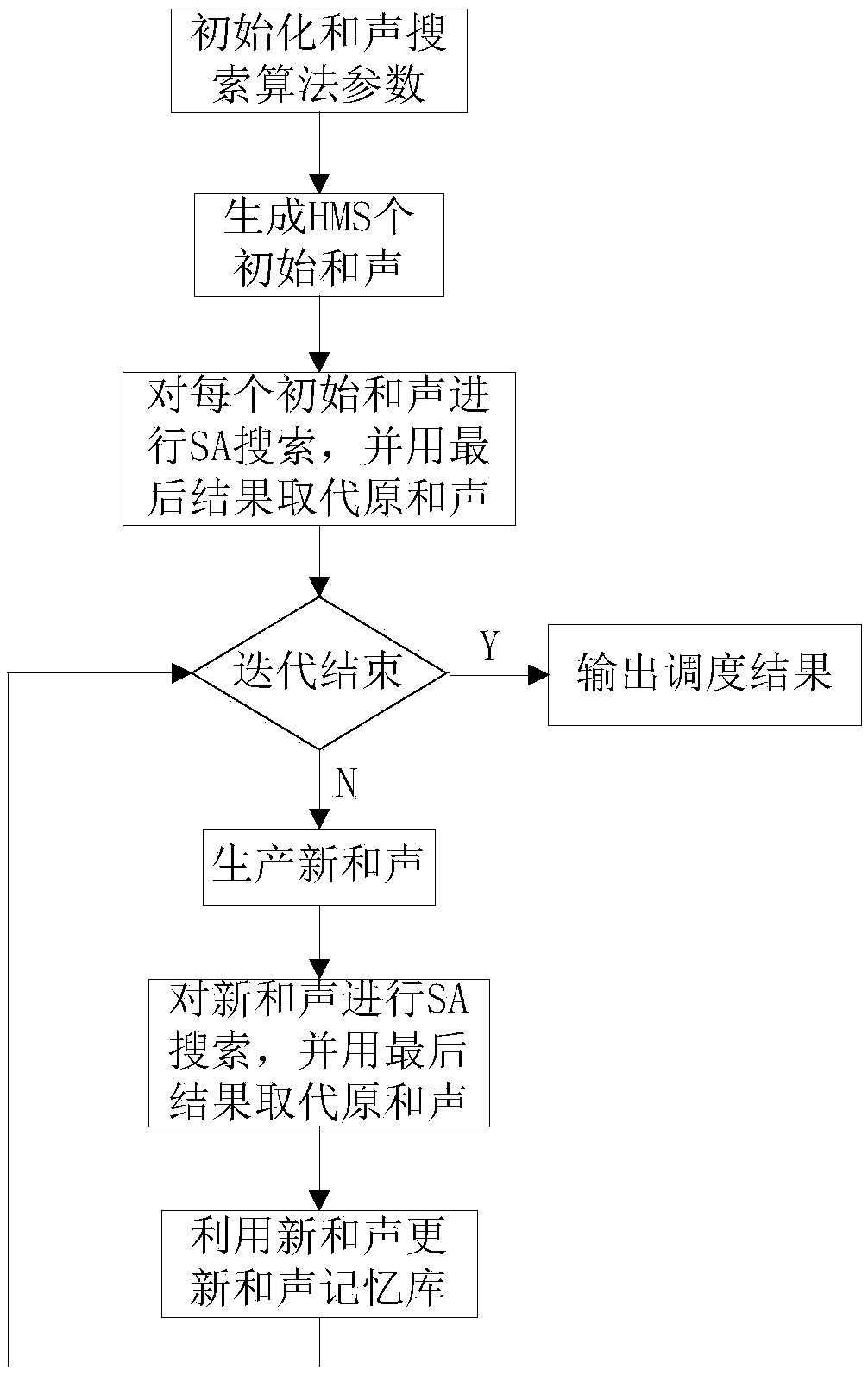

[0065] In this embodiment, the hybrid intelligent scheduling optimization method for the manufacturing enterprise workshop, the steps are as follows:

[0066] (1) Initialize the relevant parameters of the HS algorithm and the relevant parameters of the SA algorithm.

[0067] (2) According to different production tasks, input the processing information involved in each task, including the processing steps of the task, the number of batches, the required machine and the required processing time on the machine.

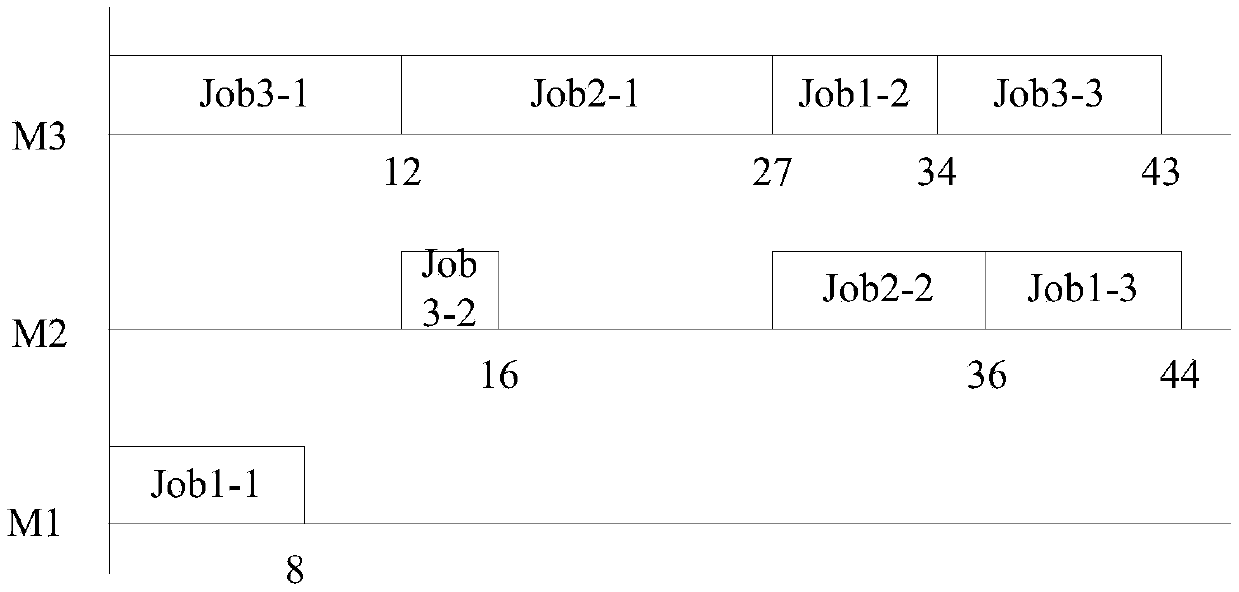

[0068] Table 1 Examples of workshop operations

[0069]

[0070] Table 1 is an example of workshop operation, can be expressed as with the input file format that the present invention stipulates:

[0071] 331

[0072] 3

[0073] 1826; 37; 28;

[0074] 2

[0075] 315; 11429310;

[0076] 3

[0077] 210312;24;39;

[0078] The data in the first row indicates that there are 3 workpieces in this job shop scheduling, the number of available machines is 3, and the bat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com