Unilayer cutting bed of weft-knitted fabric

A technology of knitted fabrics and weft knitting, which is applied in the cutting of textile materials, textiles and papermaking, etc. It can solve the problems of consuming manpower and material resources, and not necessarily getting the best solution, so as to reduce consumption, timely and high-quality production, and save costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with specific embodiment, further illustrate the present invention.

[0020] In the process of making samples and testing, a single-layer cutting bed is generally used, that is, the fabric laid on the cutting bed is generally a single layer.

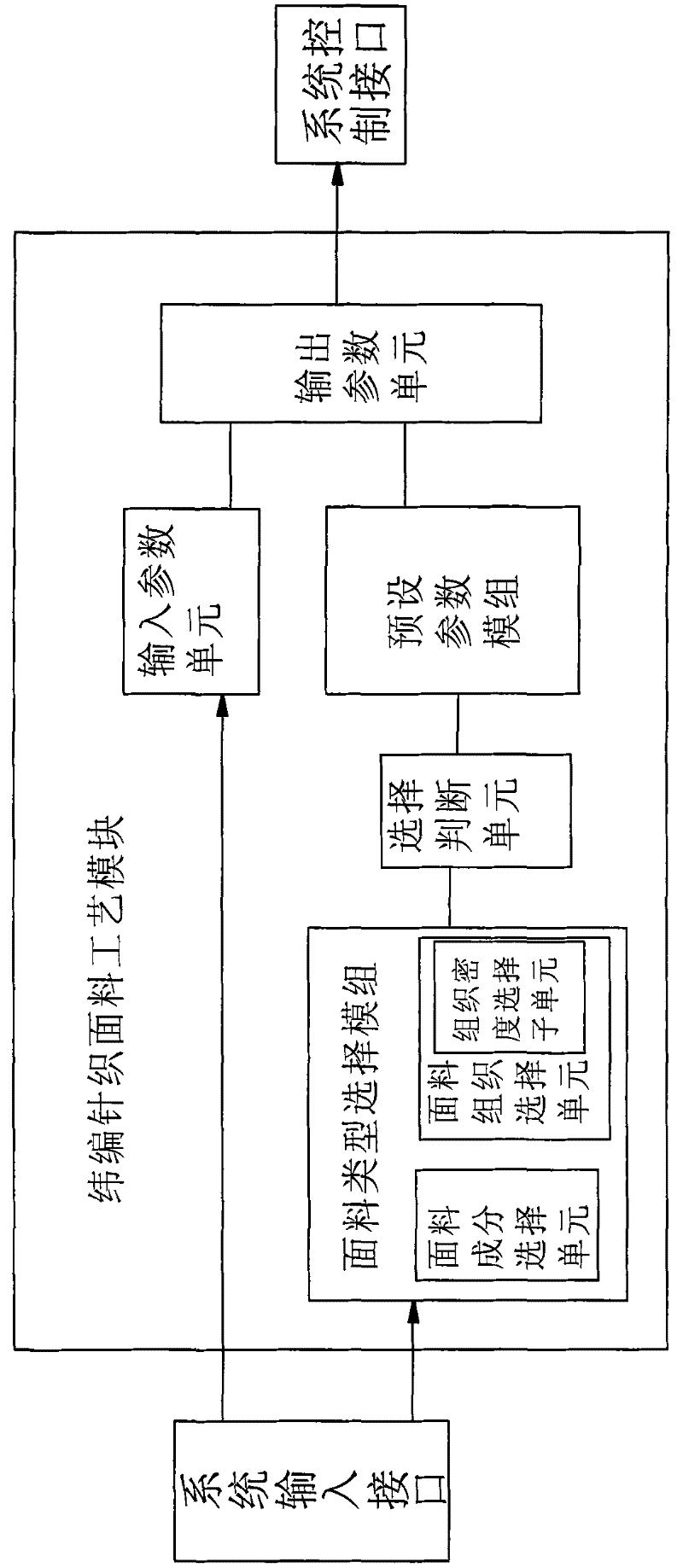

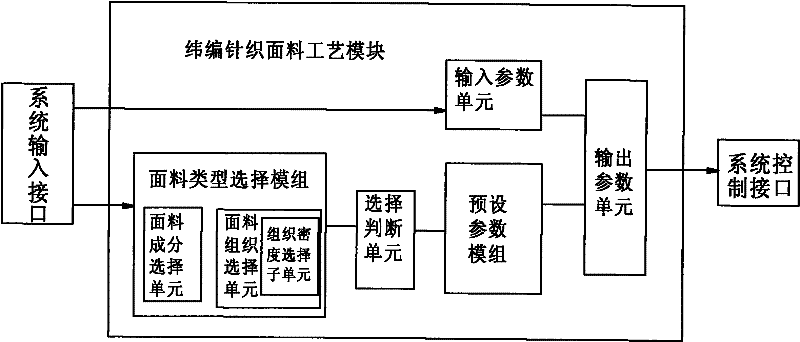

[0021] A single-layer cutting machine for weft-knitted fabrics, including a cutting table, a cutting head and a corresponding servo control system, the cutting head includes a cutting knife, a cutting knife vibrating motor, a cutting knife corner motor, a cylinder, a cutting knife Motion drive mechanism, corner movement mechanism and sharpening mechanism, the servo control system includes a weft knitted fabric process module, the process module includes a fabric type selection module, a selection judgment unit, and a preset parameter module connected behind the judgment unit , and an input parameter unit and an output parameter unit; the process module is connected to the input interface and the control interf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com