Automated winding and spot welding production line

A production line and winding technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of inconvenient operation, inability to guarantee the accuracy of spot welding products, and low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below according to accompanying drawing:

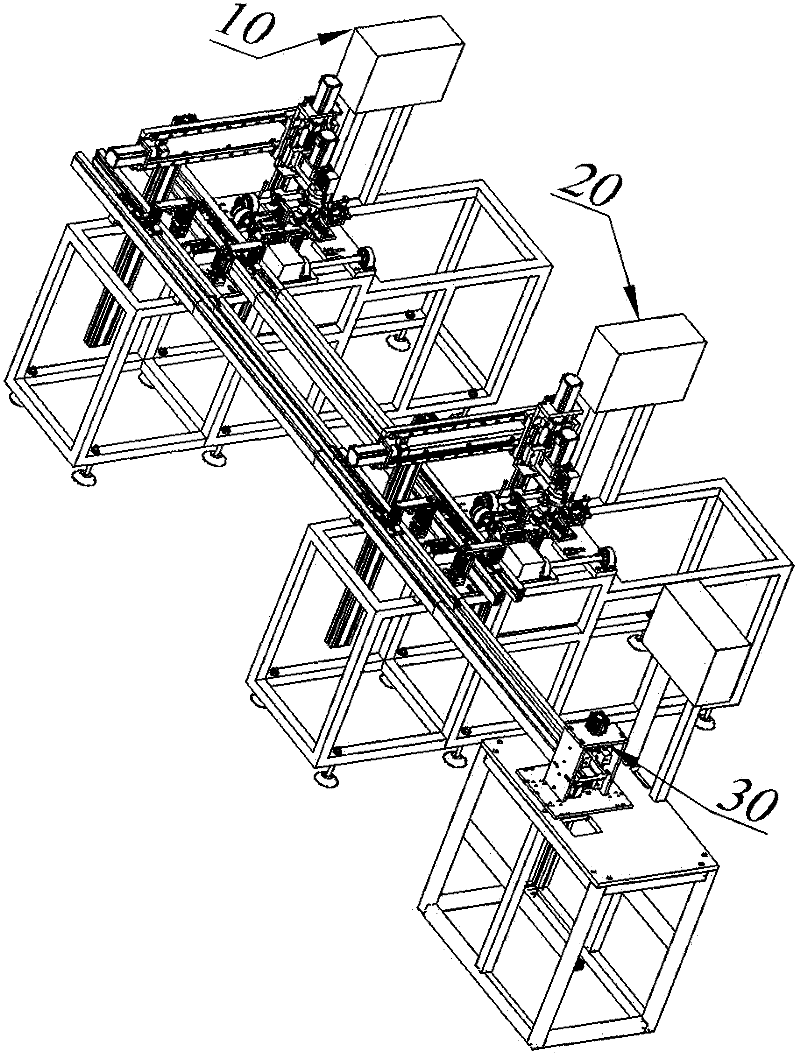

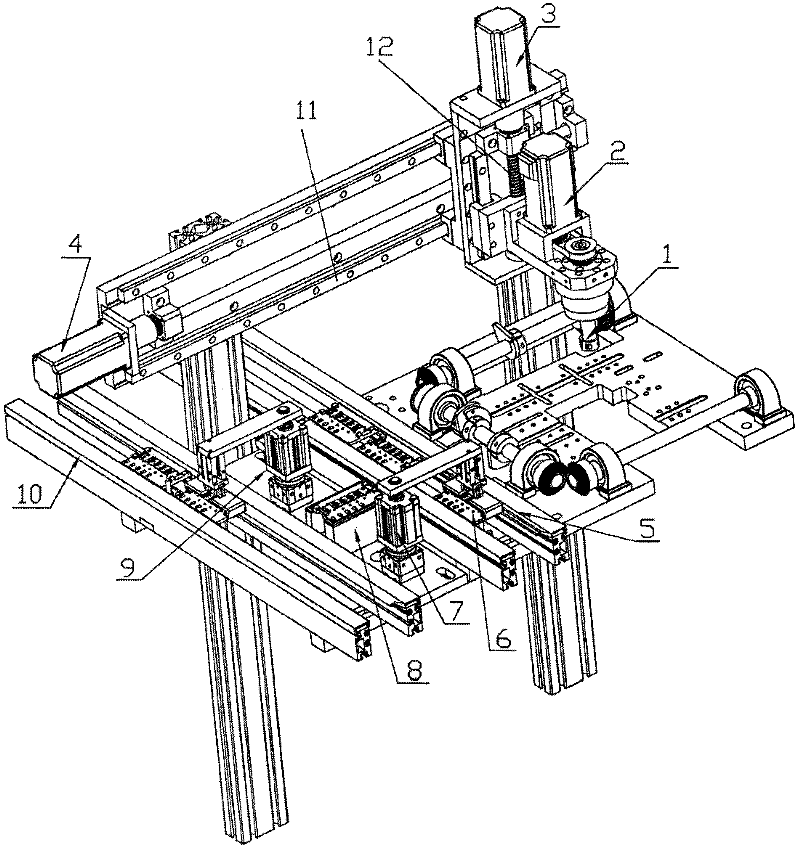

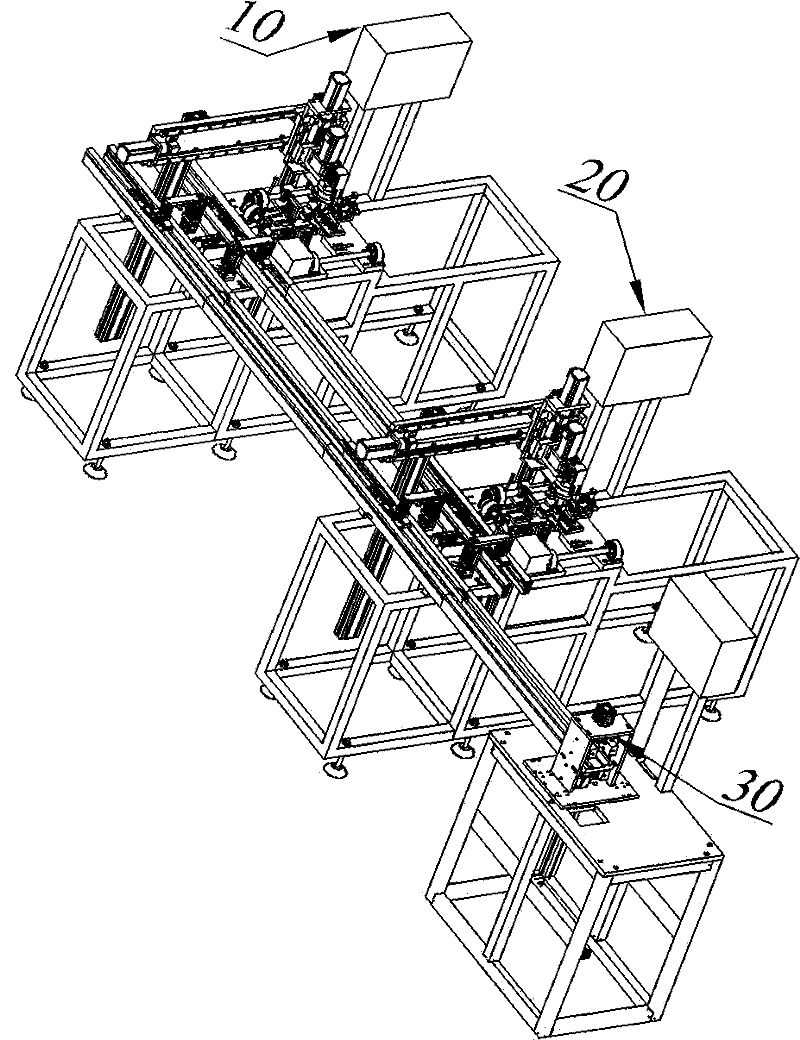

[0016] Such as figure 1 and figure 2 The shown automatic winding and spot welding production line includes a winding unit 10, a spot welding machine 30, a winding machine is set on the frame of the unit 10, and the winding machine includes a forming drive motor 2 and a winding shaft drive motor 3. Use the forming drive motor 2 and the winding shaft drive motor 3 to realize the winding work of the forming shaft 1.

[0017] The present invention can also set a winding unit 10 according to the speed of the spot welding machine, or set the winding unit 10 and the winding unit 20 at the same time, or set more winding units to work together.

[0018] The frame is also equipped with a jig plate conveying device and a manipulator 7 and a manipulator 9 matched with the jig plate conveying device. The winding machine is installed in cooperation with the slide rail 11 on the fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com