Automatic stacking device for storage battery electrode plates

A stacking device and battery technology, applied in lead-acid battery electrodes, destacking of objects, stacking of objects, etc., can solve the problems of difficulty in automating production lines, increasing labor intensity of workers, and low degree of automation, achieving structural Simple, reduce labor intensity, and improve the effect of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

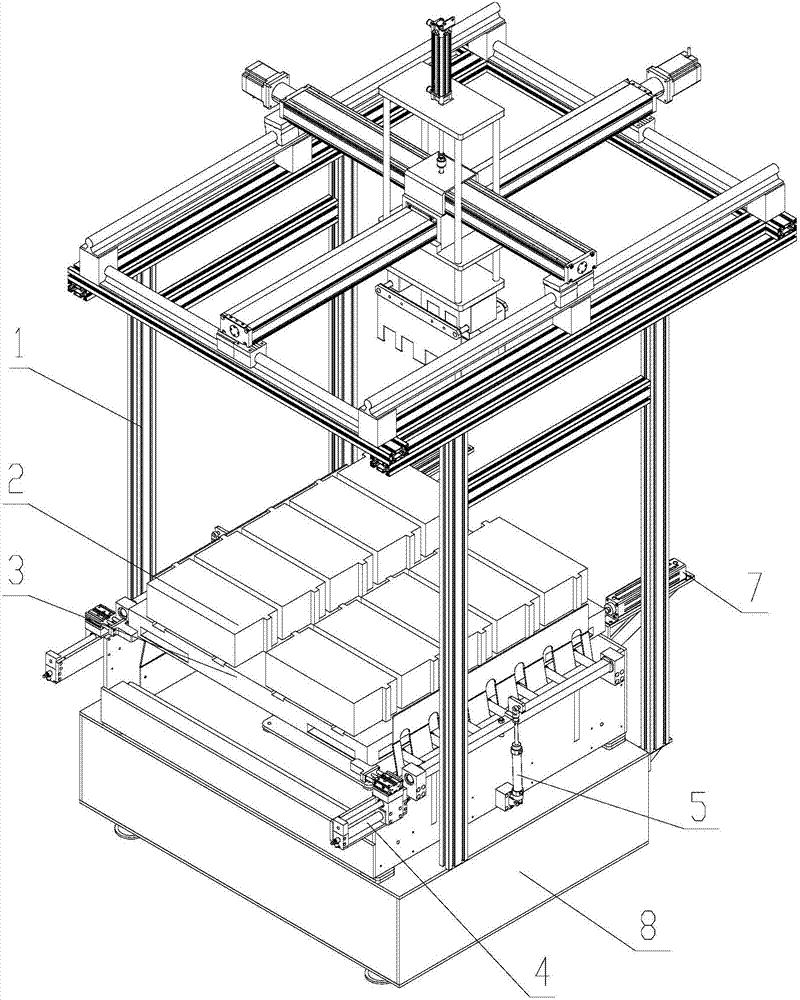

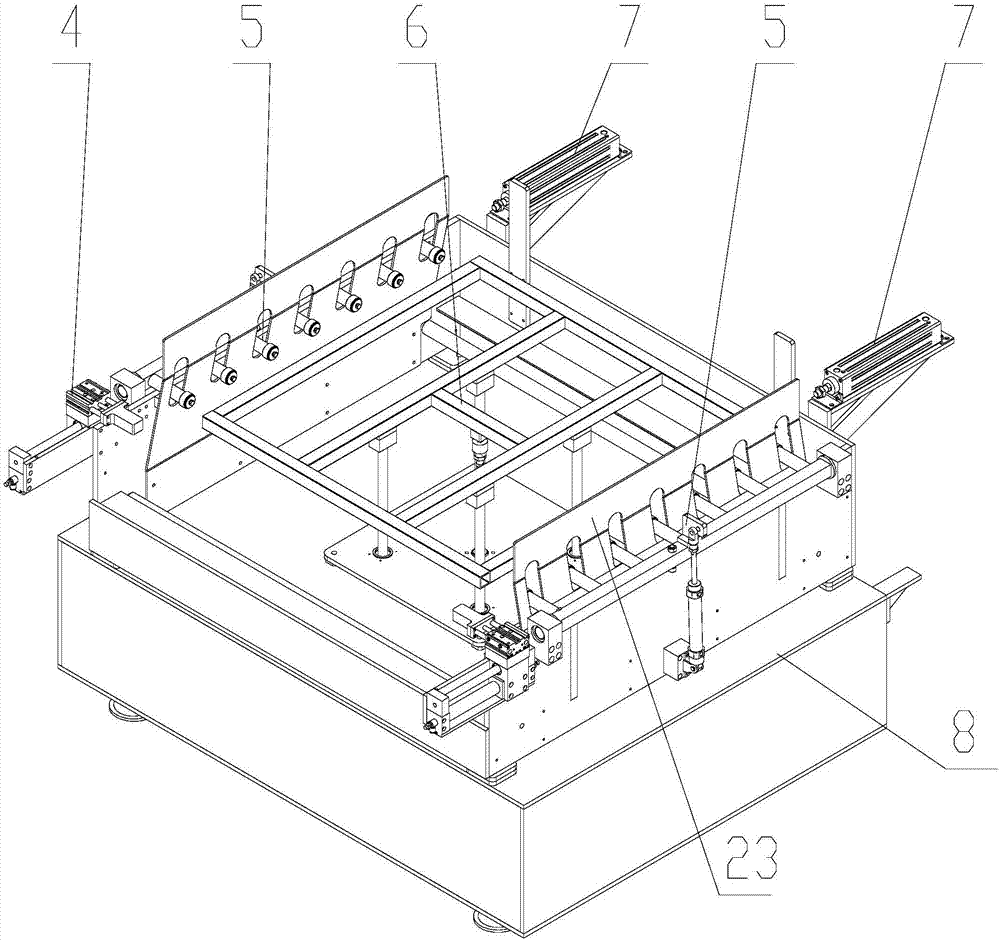

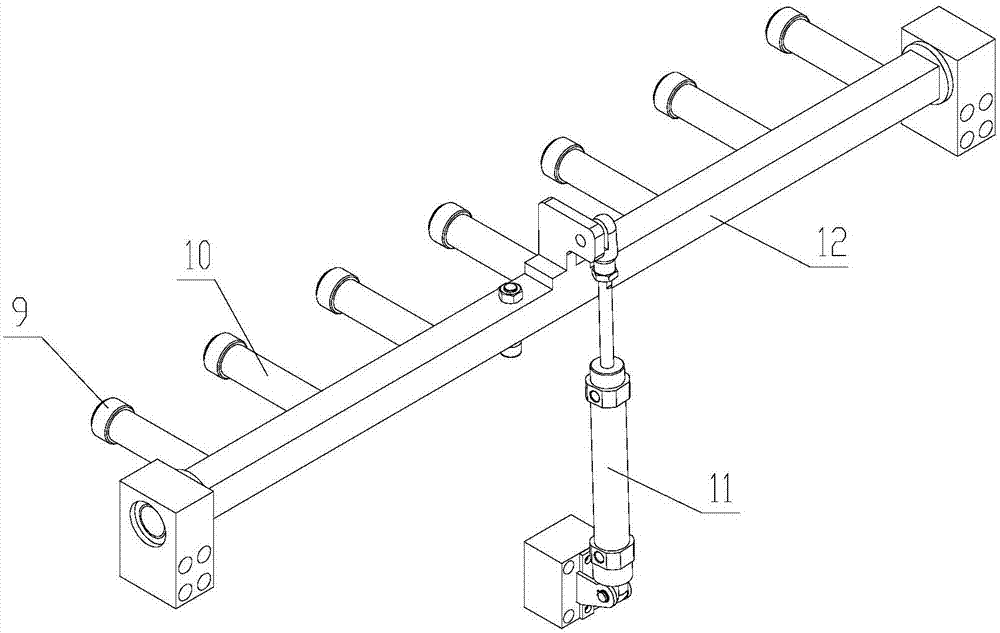

[0020] Such as Figure 1 to Figure 6 Shown: the battery pole plate automatic palletizing device of the present embodiment includes a frame 8, a lifting mechanism 6 for placing the pole plate stack tray 3 and controlling the lifting of the pole plate stack tray 3, and for carrying out the pole plate stack tray 3 The support and positioning assembly for support and positioning, the manipulator assembly 1 for automatically transporting the pole plate stack 2 into the pole plate stack tray 3, and the push mechanism 7 for pushing out the pole plate stack tray 3, the lifting mechanism 6 is arranged on the machine In the frame 8, the support and positioning assembly is fixed on the frame 8 and located on both sides of the lifting mechanism 6, the manipulator assembly 1 is detachably fixed on the frame 8 and positioned above the lifting mechanism 6, the pushing The mechanism 7 is arranged on one side of the frame 8. By adopting the above structure, it can not only realize automatic pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com