Method for producing nodular cast iron planetary supporter

A nodular cast iron, production method technology, applied in the direction of belts/chains/gears, mechanical equipment, transmission parts, etc., can solve the problems of high energy consumption, easy deformation of castings, long production cycle, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

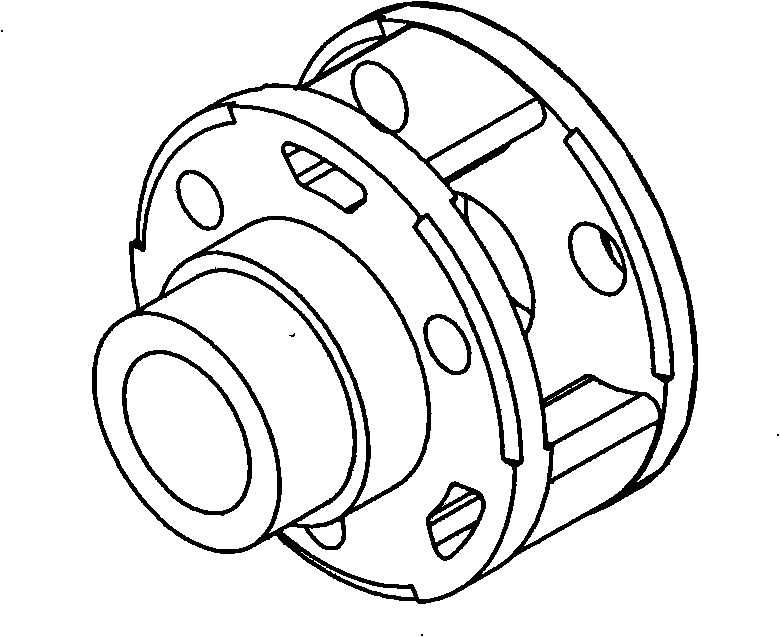

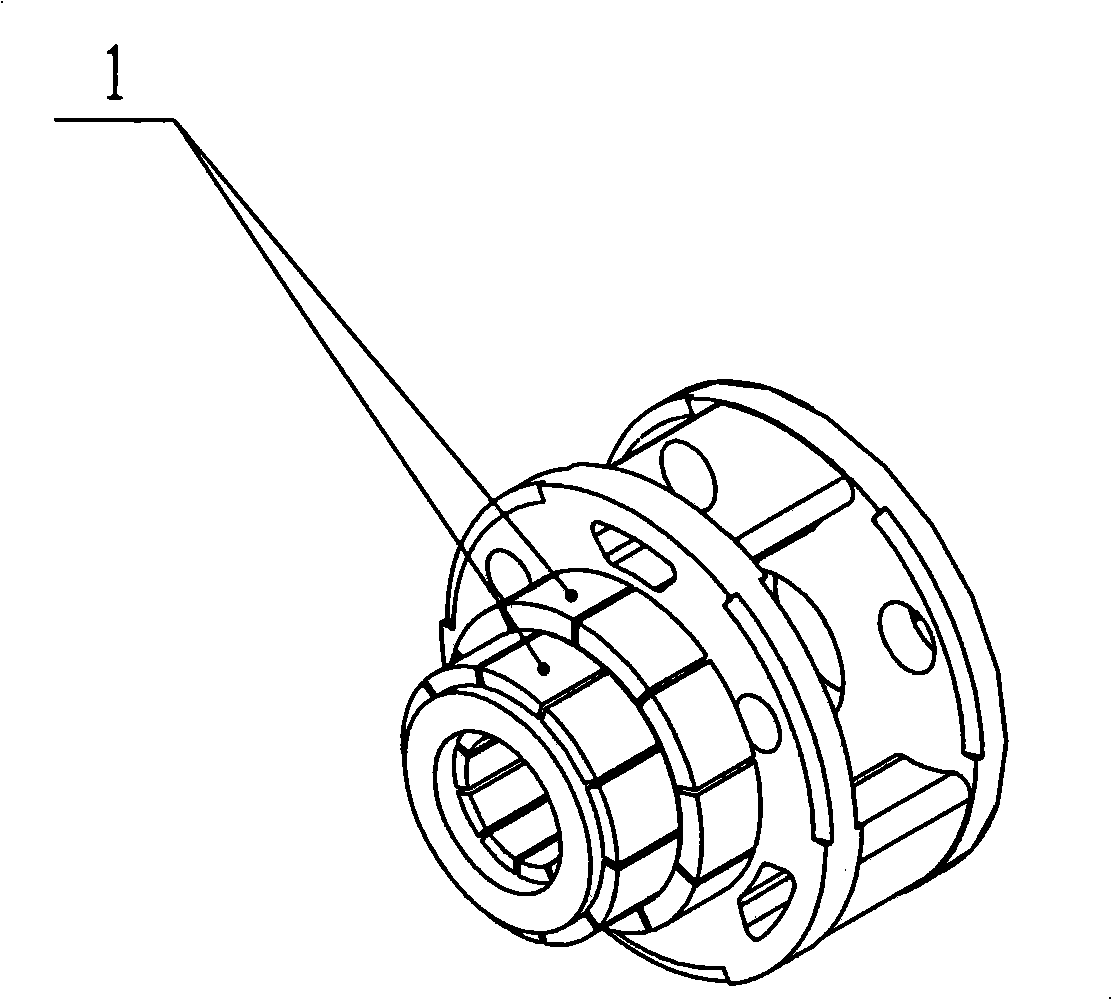

[0016] The present invention relates to a production method of a nodular cast iron planet carrier, the overall structure of the nodular cast iron planet carrier is as follows figure 1 As shown, the production method of the nodular cast iron planet carrier of the present invention includes the molten iron melting process, the spheroidizing process, the inoculation process, the pouring process, and the early unpacking and heat preservation process.

[0017] In the molten iron smelting process of the present invention, the as-cast nodular cast iron used to produce planetary carrier castings will be smelted into molten iron, and the contents of each element in the molten iron should be controlled respectively: the C content is 3.6% to 3.9%; Si content is 1.8%-2.3%; Mn content is 0.25-0.6%; P content is 0-0.06%; S content is 0-0.03%; carbon equivalent is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com