Cellar vinegar brewing technology

A cellar vinegar and process technology, which is applied in the field of solid-state fermentation cellar vinegar brewing technology, can solve the problems of long production cycle and rising production cost, and achieve the effects of improving flavor and taste, excellent quality, and clear body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] A cellar vinegar brewing process includes the following steps:

[0056] (1) Raw material moisturizing: Crush the high-quality grain raw materials corn, rice, wheat, sorghum and buckwheat, and enter the mixing tank to moisten and soak for 30 minutes;

[0057] (2) Cooking: The raw materials after being moistened are heated to 95-98℃ in the mixing tank to liquefy;

[0058] (3) Saccharification and alcoholization: Daqu saccharifying agent is added to the clinker after cooking, saccharification and alcoholization are carried out to prepare alcoholic mash;

[0059] (4) Acetic acid fermentation: mix wheat bran, chaff and other auxiliary materials with wine mash, connect black koji and acetic acid strains for multi-strain fermentation to produce vinegar, the cycle is 25-30 days.

[0060] (5) After the fermented vinegar mash is transferred to the vinegar pit mud tank 1, it is sealed with pit vinegar mud 1 and fermented again for a period of 30 days.

[0061] (6) Pour vinegar: the mature vi...

Embodiment 2

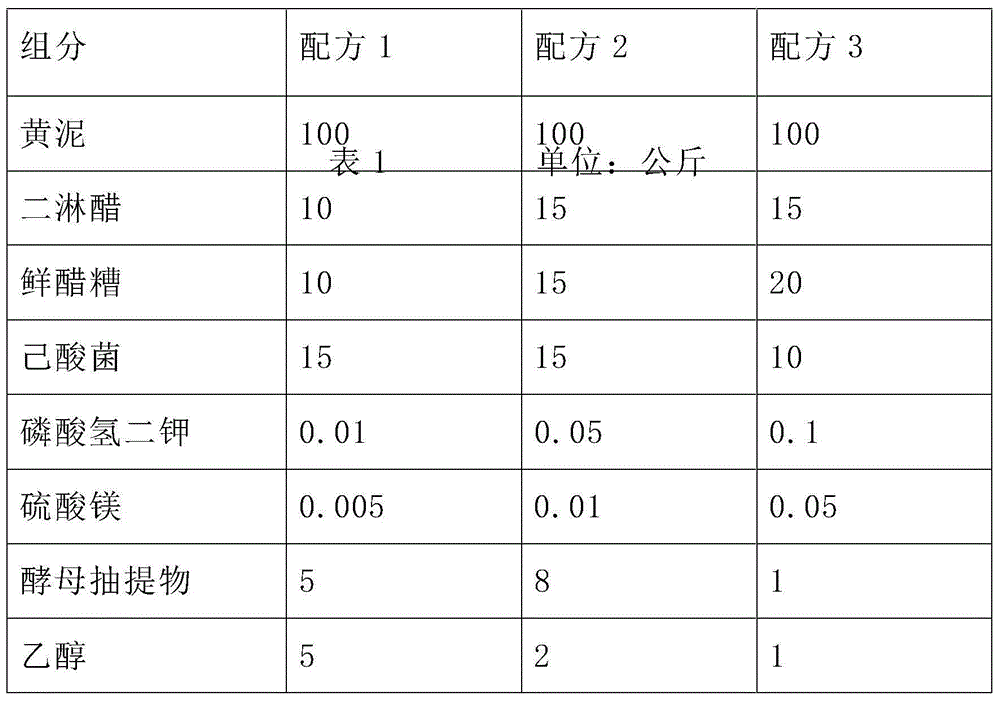

[0067] A pit vinegar brewing process, except for step (5), the rest is the same as in Example 1.

[0068] (5) After the fermented vinegar mash is transferred to the vinegar pit mud tank 2, it is sealed and fermented again with the pit vinegar mud 2 for a period of 30 days.

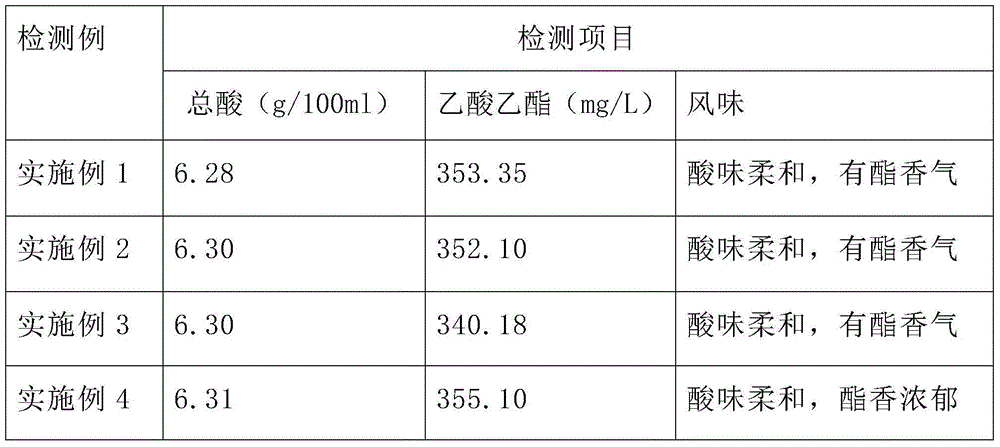

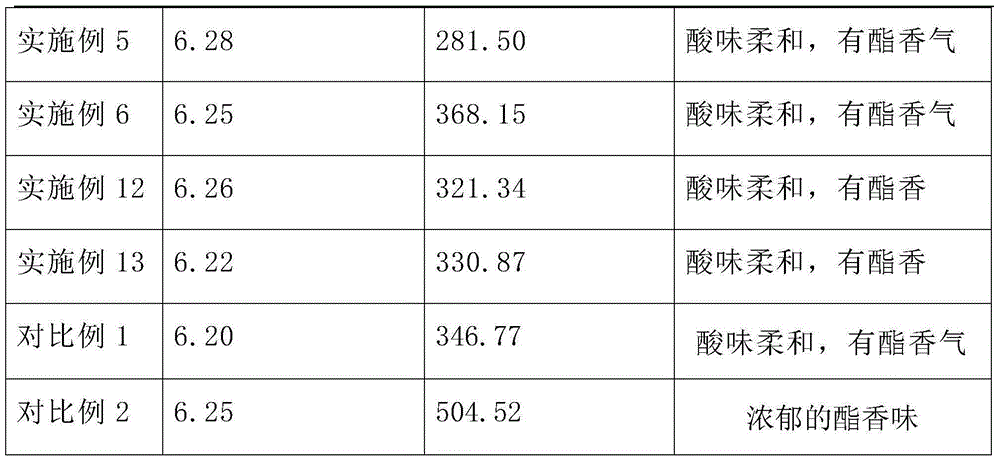

[0069] In step 6, the mixed vinegar of the first raw juice vinegar and the first rind vinegar was tested. The data is shown in Table 3.

Embodiment 3

[0071] A pit vinegar brewing process, except for step (5), the rest is the same as in Example 1.

[0072] (5) After the fermented vinegar mash is transferred to the vinegar pit mud tank 3, it is sealed with the pit vinegar mud 3 and fermented again for a period of 30 days.

[0073] In step 6, the mixed vinegar of the first raw juice vinegar and the first rind vinegar was tested. The data is shown in Table 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com