Process for manufacturing ice zone bulbous bow reinforcing structure by sections

A manufacturing process and strengthening structure technology, which is applied in the field of segmented manufacturing process of the reinforced structure of the bulbous bow in the ice area, can solve the problem that the same or similar technical solutions are not found, and achieve the expansion of the assembly workload, shorten the construction period, and improve the welding quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

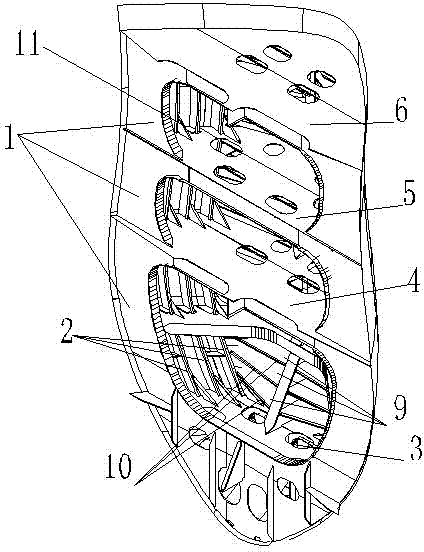

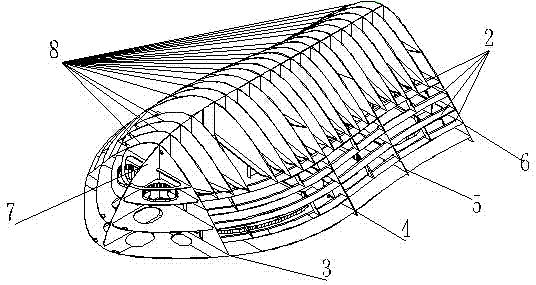

[0034] The invention discloses a manufacturing process of a bulbous bow reinforcement structure in an ice region, which involves a bulbous bow reinforcement structure in an ice region, such as Figure 1-3 As shown, it includes a strong rib frame 1, a rib 2, and four layers of the first layer of platform board 3, the second layer of platform board 4, the third layer of platform board 5, and the fourth layer that are vertically arranged on the strong rib frame 1 from top to bottom. Four-layer platform slab 6, the central longitudinal axis of the four-layer platform is fixed on the end face of the strong rib frame 1 by the platform bow middle longitudinal stringer; Plate 7 and several bulkheads 8 welded in pairs on both sides of the longitudinal plate 7, the bulkheads 8 are welded on both sides of the longitudinal plate 7 in a T shape; On the platform 2 between the strong rib frames 1, there are several outer plates 12, which cover the outer surface formed by the longitudinal gir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com