Disposable slipper producing device

A kind of production equipment and one-time technology, applied in the direction of footwear, adhesive shoe parts, shoe-making machinery, etc., can solve the problem of low degree of mechanization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

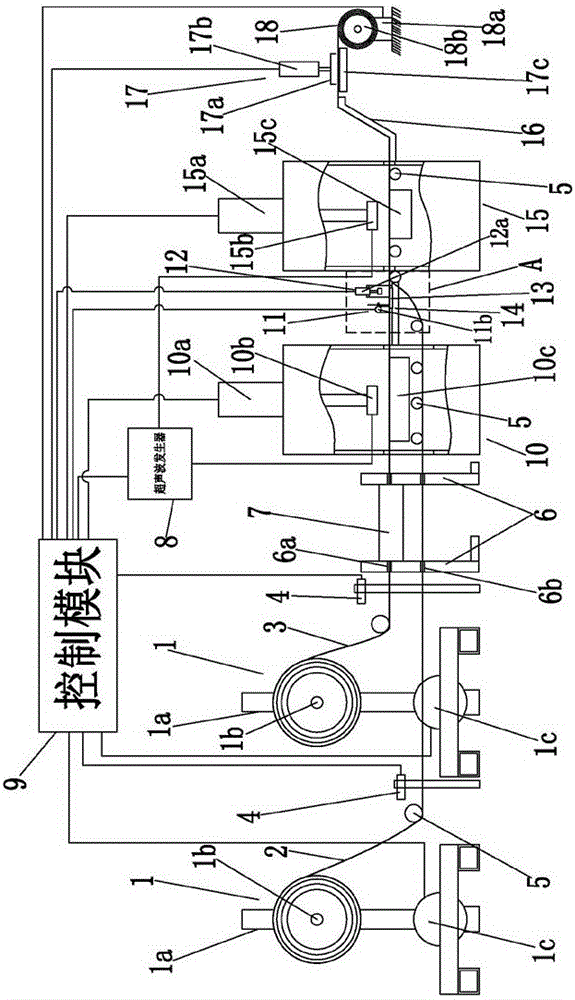

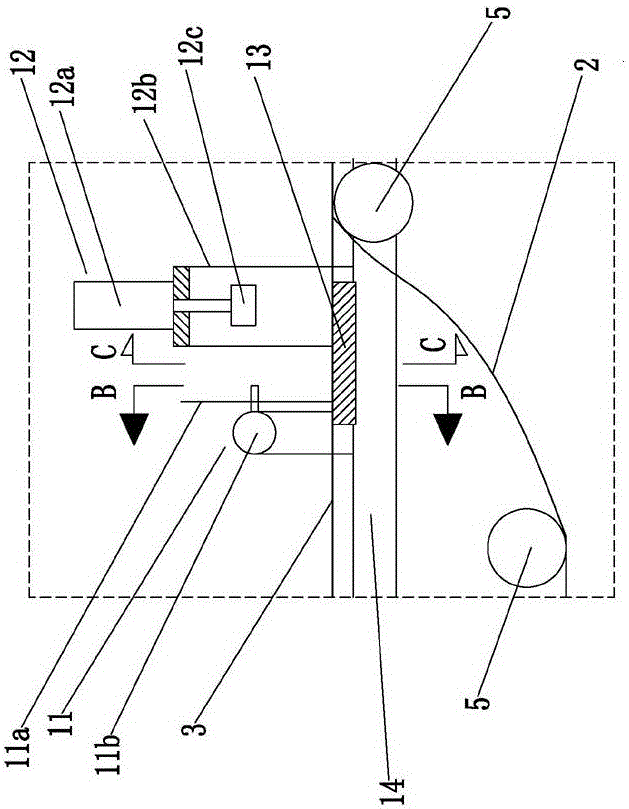

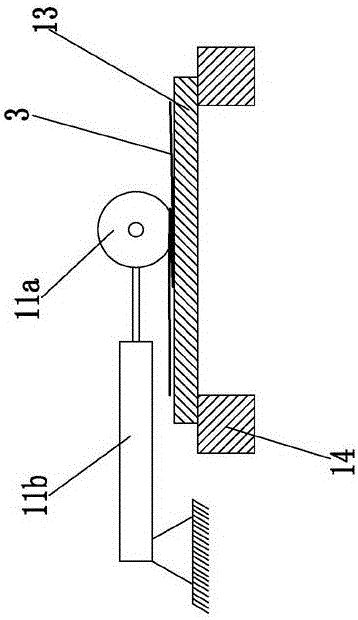

[0023] Such as Figure 1-4 As shown, a disposable slipper production equipment, according to the production process, sequentially includes two feeding devices 1, a shoe upper hemming device that can bend the shoe upper fabric 3, and can iron and press the bent shoe upper fabric 3 Formed ironing press 10, molding press 15 that can press upper fabric 3 and sole fabric 2 into one, slope guide table 16, final forming device 17 that can directly cut finished products, winding device 18, also includes A plurality of feeding rollers 5 that resist the shoe upper fabric 3 and the shoe sole fabric 2 and control the conveying direction and relative position of the two. A fixed beam 14 is provided between the iron press 10 and the mold press 15, and a cutting tool for placing the shoe upper fabric 3 is arranged. Cutting platform 13, cutting device 11, pressing device 12 that can press the upper fabric 3 when cutting the upper fabric 3; the slope type guide table 16 accepts the outlet end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com