Corrugated paper pressure damage-free transmission device of paper mounting machine and paper mounting machine

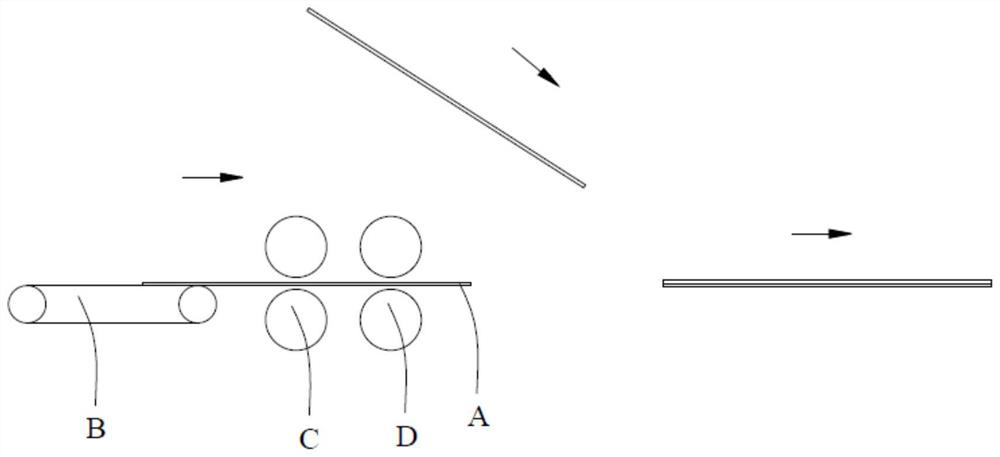

A transmission device, corrugated paper technology, which is applied in pasting, decorative arts, transportation and packaging, etc., can solve problems such as affecting production efficiency, affecting transmission efficiency, and stress damage of backing paper, and achieves stable conveying, stable transmission, and reduction of stress damage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

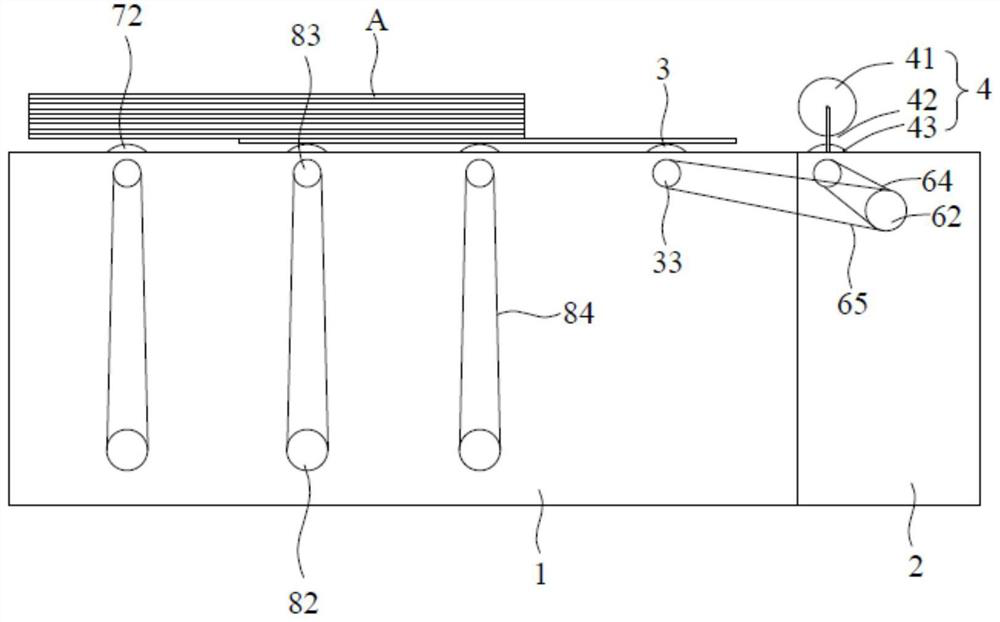

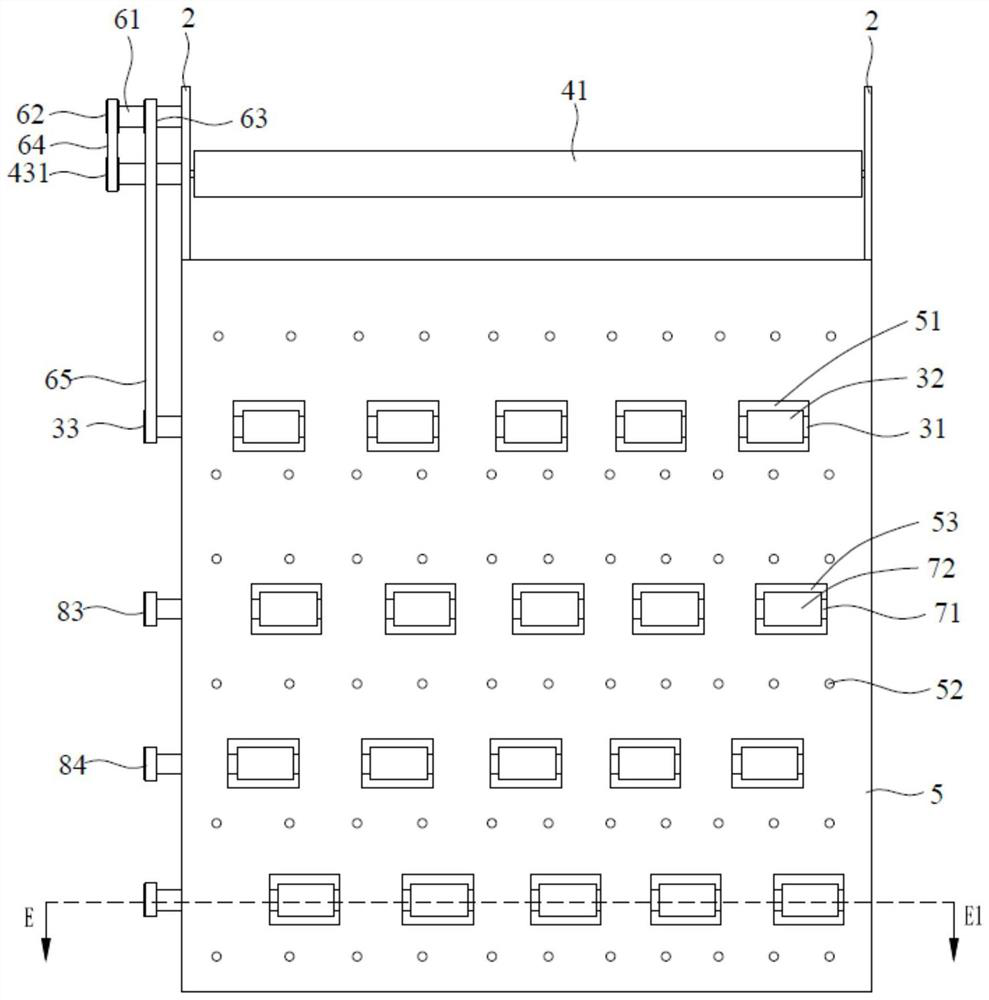

[0039] Such as Figures 2 to 4As shown, the embodiment of the present invention provides a pressure-damage-free transmission device for corrugated paper of a laminating machine, including two sets of front edge mounting plates 1 and two sets of rear edge mounting plates 2, a pair of front edge mounting plates 1 and rear edge mounting plates 2 One set side by side, the two groups of front edge mounting plates 1 are provided with a conveying wheel set 3, and the two groups of trailing edge mounting plates 2 are provided with an upper rubber wheel set 4; the conveying wheel set 3 includes a rotating set On the conveying shaft 31 between the two groups of said front edge mounting plates 1, several conveying wheels 32 are arranged on said conveying shaft 31, and the equidistant coaxial arrangement between several conveying wheels 32 is arranged on the conveying shaft 31, two groups The top of the front edge mounting plate 1 is connected by a top plate 5, and the top plate 5 is prov...

Embodiment 2

[0047] Embodiments of the present invention On the basis of Embodiment 1, the embodiments of the present invention provide a laminating machine including the corrugated paper transmission device described in Embodiment 1 without pressure damage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com