Staged fracturing construction method for long well section

A staged fracturing and construction method technology, applied in the field of fracturing construction, can solve the problems of soluble bridge plug sealing performance, great influence on dissolution performance, increase treatment measures, difficulty in lowering tools, etc., to save operating time and cost , avoid the risk of downhole operation, and avoid the effect of drilling and grinding operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] In the following description of the present invention, the orientation or positional relationship indicated by the terms "upper", "lower", "front", "rear", "left", "right", "inner", "outer", etc. is based on the attached The orientation or positional relationship shown in the figures is only for the convenience of describing the present invention and simplifying the description, and does not mean that the device must have a specific orientation. In horizontal wells, those closer to the bottom of the well are referred to as "below", and those closer to the wellhead are referred to as "above".

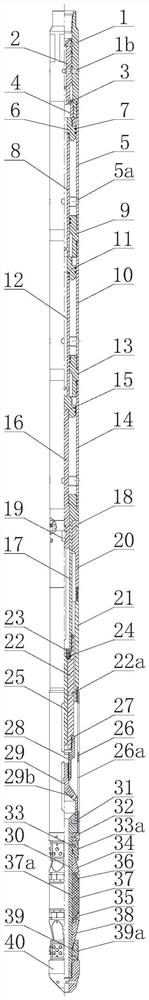

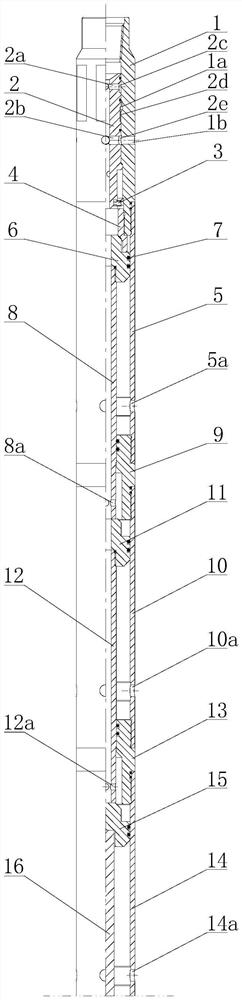

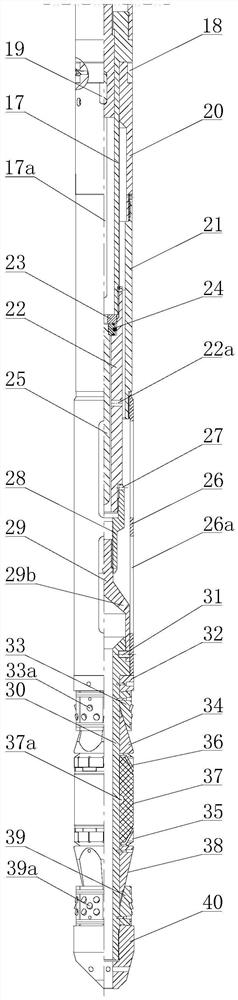

[0055] like Figure 1 to Figure 3 As shown, the plugging combined tool used in the present invention sequentially includes a slide valve, a setting driving mechanism, a pressure detection mechanism and a soluble bridge plug from top to bottom. The valve body cavity of the slide valve 1 is provided with a valve core 2; the setting drive mechanism includes an upper cylinder liner 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com