Protection tool and method for square socket during spraying of printed piece

A technology for protecting tooling and squares, which is applied to the device for coating liquid on the surface, spraying device, coating, etc., which can solve the problems of low efficiency, waste of tape, labor and time, etc., to improve safety, improve quality and process Efficiency, anti-static effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

[0045] The invention relates to a tool and a method for protecting a square socket when a printed part with a square socket is sprayed.

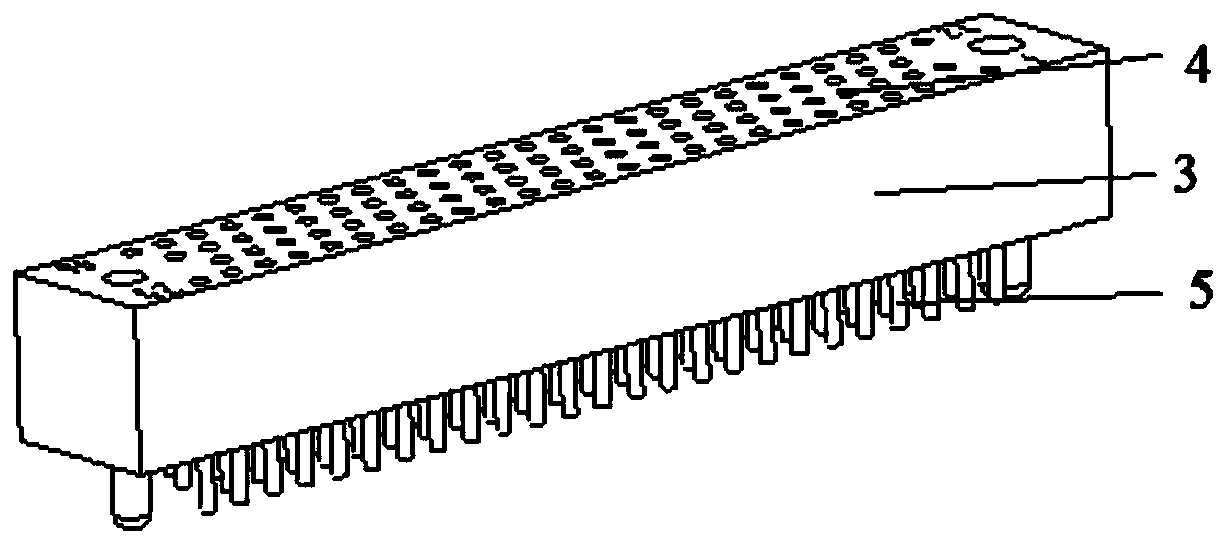

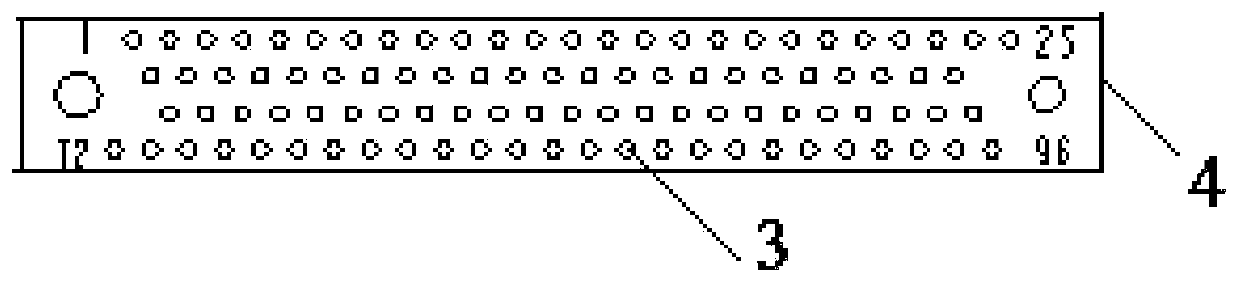

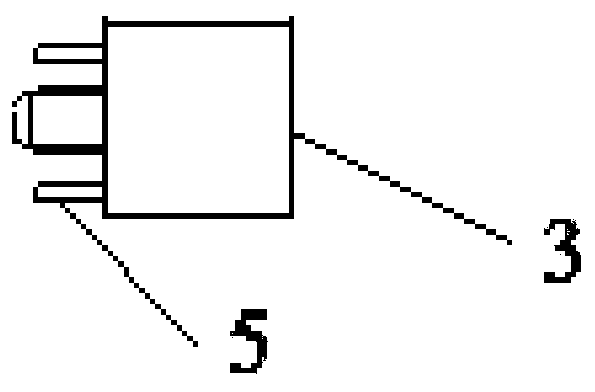

[0046] The present invention is a protective tooling for a square socket when spraying printed parts, including a protective shell 1 and a sealing layer 2; specifically, the protective shell 1 is in the shape of a strip, and the cavity of the protective shell 1 is similar in shape to the square socket shell 3. The two ends of the protective shell 1 are opened, and the opening of the protective shell 1 is the same as the cross-sectional shape of the square socket housing 3; It is a flexible material, and the sealing layer 2 is sealed at the opening of the protective shell 1;

[0047] When in use, the protection tool expands outwards along its width directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com