Ultrasonic monitoring device for residual stress of steel structure

A residual stress and monitoring device technology, applied in measuring devices, force/torque/work measuring instruments, instruments, etc., can solve problems such as slow detection speed, poor accuracy, and complicated installation, and achieve tight protection, easy portability, and airtightness Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

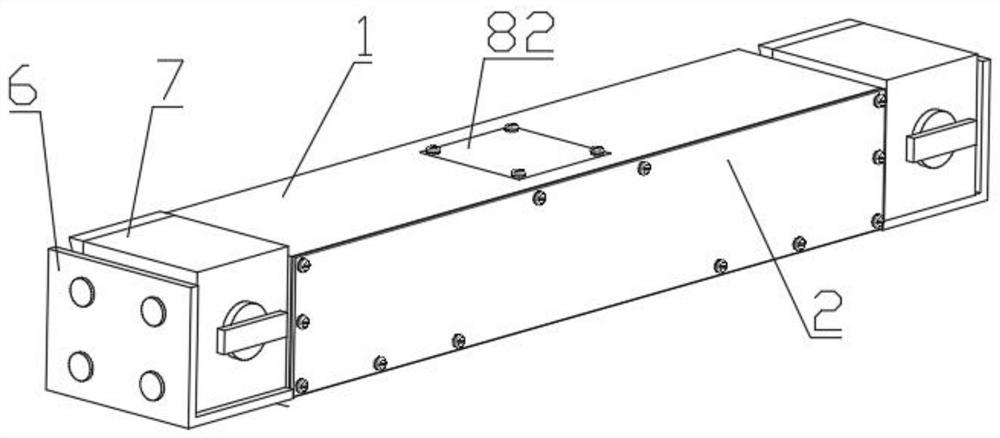

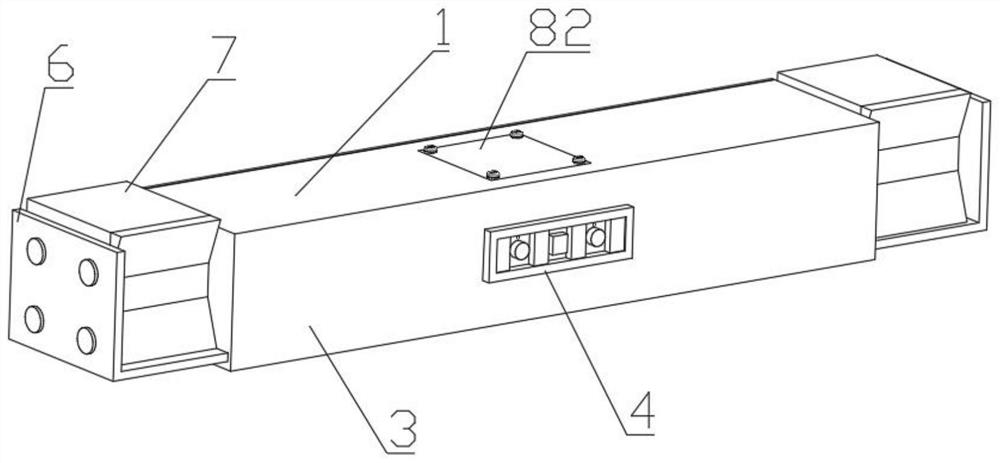

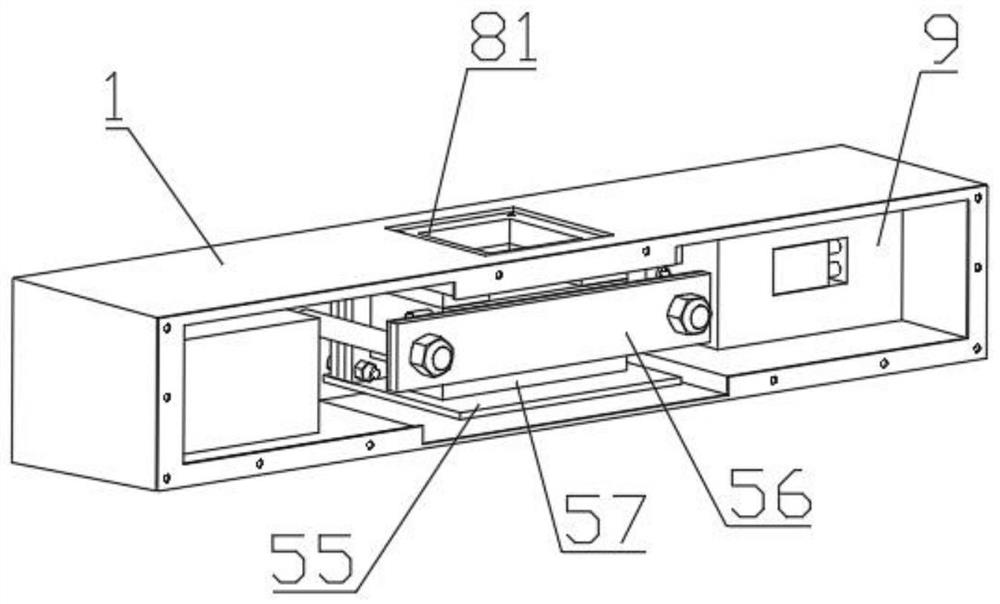

[0035] An ultrasonic monitoring device for steel structure residual stress, the key is: including a positioning box 1, a detection device installed on the positioning box 1, a power supply device and an information processing transmitting device, and the power supply device transmits the detection device and information processing by means of wires Power supply is installed, and the signal output terminal of the detection device is connected with the information processing transmitting device by means of a line;

[0036] The positioning box 1 is open on one side away from the steel structure 1 and is fixed with a side sealing cover 2 by means of screws. The side of the positioning box 1 opposite to the side sealing cover 2 is the installation part 3. Two magnetic bases 7 are fixed by means of triangle iron 6 and bolts;

[0037] Described detection d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com