Efficient explosionproof halogen lamp and manufacturing method thereof

A halogen lamp, high-efficiency technology, used in incandescent lamps, incandescent lamp energy saving, incandescent lamp parts and other directions, can solve the problems of high surface temperature of the bulb, easy to emit fire, poor ultraviolet absorption, etc., to achieve convenient and safe use, improve luminescence The effect of high efficiency and luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

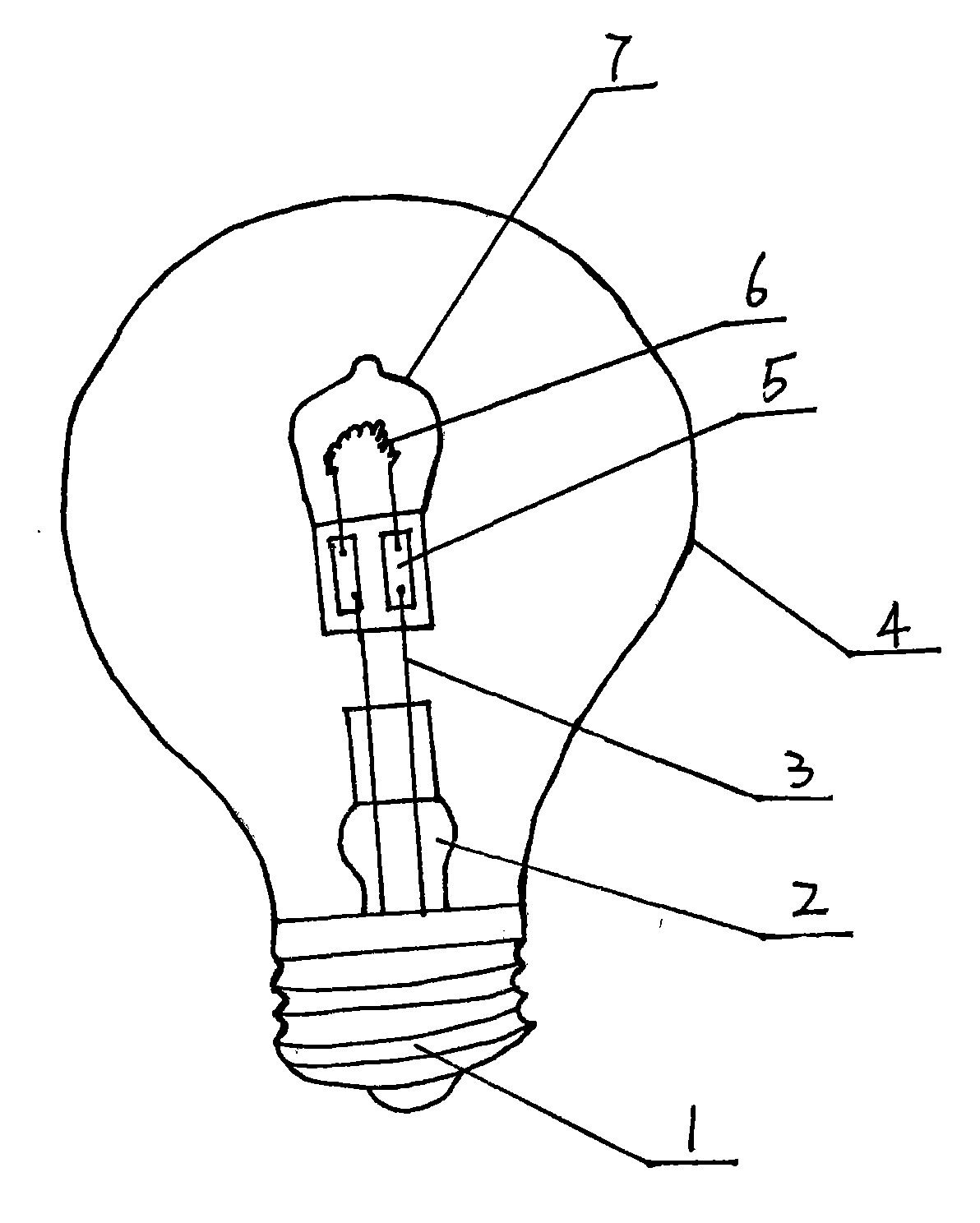

[0017] Example 1. refer to figure 1 . A high-efficiency explosion-proof halogen lamp, including a lamp cap 1 and a bulb 4, a halogen lamp, a positive and negative electrode connecting rod 3 and an insulating seat 2 are also arranged in the bulb 4, and the insulating seat 2 is fixed on the lamp cap 1, The halogen lamp includes a quartz lamp housing 7, in which a molybdenum sheet 5 and a tungsten wire 6 are arranged, and the quartz lamp housing 7 is filled with halogen gas, and the positive and negative connecting rods 3 are fixed on insulating On the seat 2, one end of the positive and negative connecting rod 3 is respectively connected to the positive and negative poles of the lamp cap 1, and the other end is respectively connected to the molybdenum sheet 5 of the halogen lamp, and the bulb 4 is filled with inert gas.

Embodiment 2

[0018] Example 2. According to the high-efficiency explosion-proof halogen lamp of claim 1, said inert gas is krypton or neon.

Embodiment 3

[0019] Example 3. A production method for a high-efficiency explosion-proof halogen lamp as described in Embodiment 1 or 2, firstly fix the positive and negative electrode level connecting rods 3 on the insulating base 2, take the halogen lamp, and fix one end of the positive and negative electrode level connecting rods 3 Connect to the molybdenum sheet 5 of the halogen lamp; then take the lamp cap 1, fix the insulating seat 2 on the lamp cap 1, and connect the positive and negative electrode connecting rods 3 to the positive and negative poles of the lamp cap 1; then take the bulb 4, Connect it to the lamp cap 1, vacuumize the inside of the bulb shell 4 and fill it with inert gas, and seal and fix the lamp cap 1 and the bulb shell 4 at the same time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com