Device and method for treating ship tail gas with sea water washing

A technology for ship exhaust and seawater, applied in separation methods, chemical instruments and methods, and separation of dispersed particles, can solve the problems of poor treatment effect and high energy consumption, and achieve the effect of less water demand and convenient port state inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

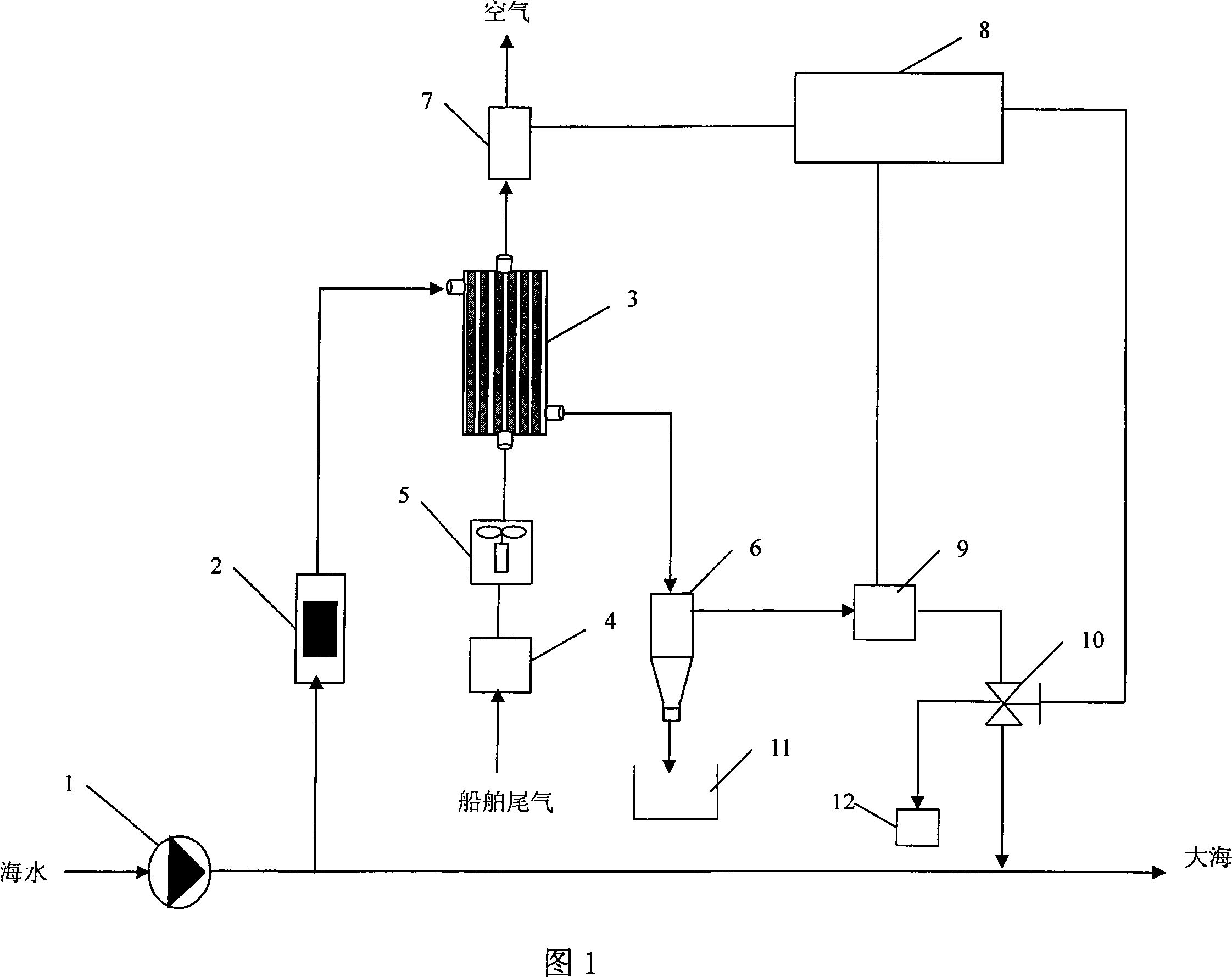

[0012] The present invention is described in further detail below in conjunction with accompanying drawing:

[0013] As shown in Figure 1, the device of the present invention that carries out seawater washing treatment to ship tail gas mainly consists of seawater pump 1, electromagnetic flow meter 2, hollow fiber membrane contactor 3, electrostatic precipitator 4, axial flow fan 5, solid-liquid cyclone Stream separator 6, SO 2 Concentration monitor 7, PLC programmable controller 8, water quality monitor 9 and solenoid valve 10 are composed.

[0014] After being pretreated by the electrostatic precipitator 4, the exhaust gas from the ship chimney is sent to the fiber tube of the hollow fiber membrane contactor 3, that is, the scrubber, through the axial flow fan 5. In the scrubber, the exhaust gas from the ship is scrubbed by seawater. The seawater used for washing ship exhaust is pumped into the scrubber after being metered by the electromagnetic flowmeter 2 by a special sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com