Preparation method and product of cheese by using monascus sp.

A technology for Monascus and cheese, which is applied in the field of preparation of Monascus cheese, can solve problems such as slow growth of Monascus, and achieve the effects of enhancing immunity, increasing nutritional value, and anti-fatigue immunity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

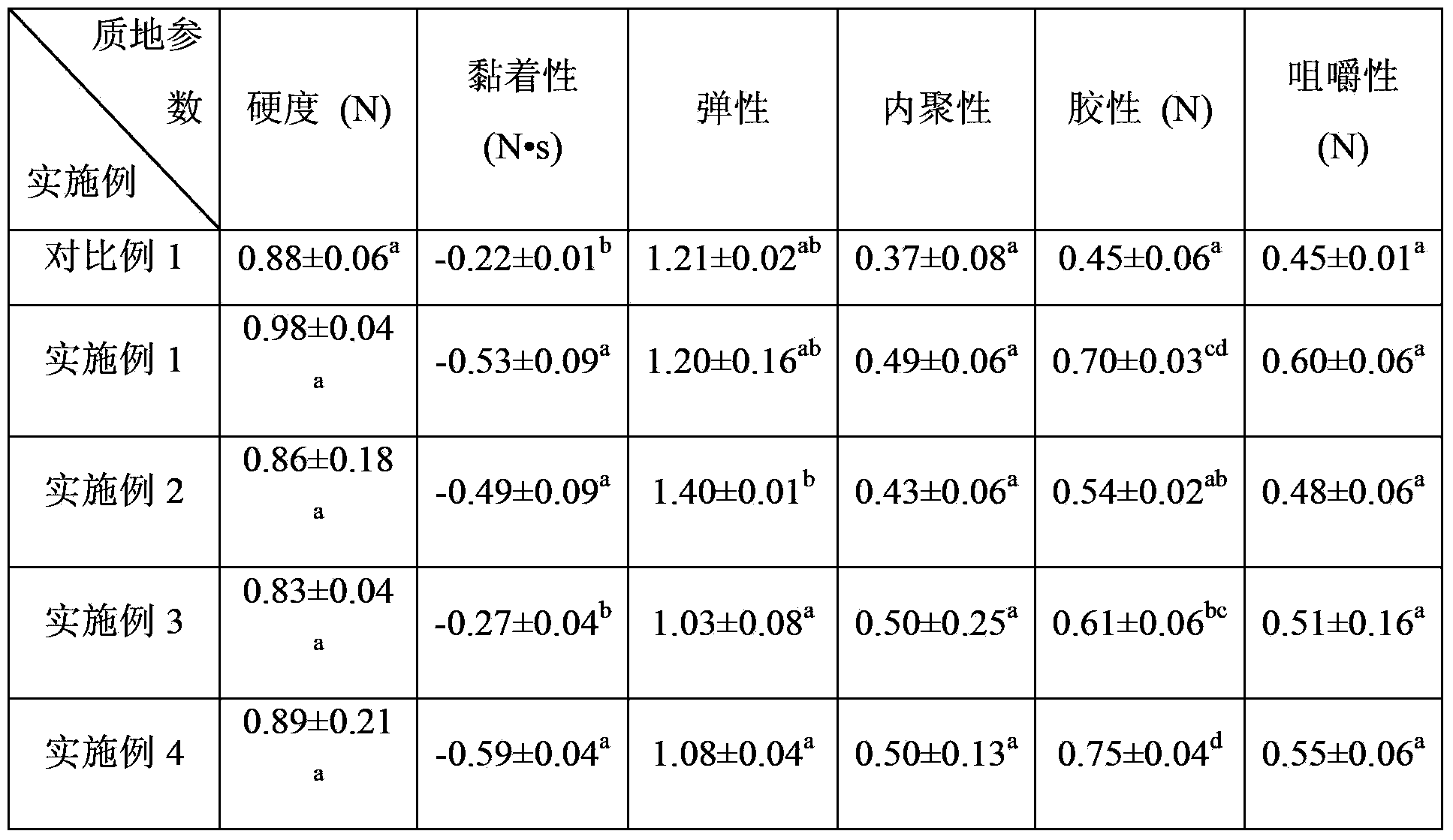

Examples

Embodiment 1

[0042] Ingredients used in this example: 50L of fresh milk, 1g of starter R-704, 0.5g of calf gastric rennet, GL-1 of frozen Monacus sp., 1.3kg of salt, 20g of glucose, 2.5g of peptone, MgSO 4 0.25g, K 2 HPO 4 0.25g, rice cereal (50%w / v) 500g.

[0043] Preparation steps:

[0044] (1) 50L of fresh milk was filtered to remove impurities, sterilized at 72°C for 2 minutes, and then cooled to 28°C to obtain processed milk. Inoculating starter R-704 into the treated milk, the inoculation amount is 1g / 50L, and culturing at a constant temperature of 28°C to a pH of 6.5, adding 0.5g calf gastric rennet, and curdling the milk for 30min to obtain curd;

[0045] (2) Cut the curd obtained in step (1) into blocks, and stir for 10 minutes to drain the whey; after the whey is drained, add 2.5% salt to the curd, and the percentage is the percentage of the salt in the curd. % by mass, stir evenly and put it into a square mold;

[0046] (3) After the curd is put into the mold, put a small ...

Embodiment 2

[0050] Ingredients used in this example: 50L of fresh goat milk, 0.3g of starter R-704, 1g of microbial rennet, frozen Monacus sp. GL-1, 1kg of salt, 20g of glucose, 2.5g of peptone, MgSO 4 0.25g, K 2 HPO 4 0.25g, rice cereal (70%w / v) 300g.

[0051] Preparation steps:

[0052] (1) 50L of fresh goat milk was filtered to remove impurities, sterilized at 72°C for 5 minutes, and then cooled to 35°C to obtain processed milk. Inoculating starter R-704 into the treated milk, the inoculation amount is 0.3g / 50L, and culturing at a constant temperature of 34°C until the pH is 6.0, adding 1g of microbial rennet, and curdling the milk for 40min to obtain curd;

[0053] (2) Cut the curd obtained in step (1) into blocks, and stir for 10 minutes to drain the whey; after the whey is drained, add 1% salt to the curd, and the percentage is that the salt accounts for the curd. % by mass, stir evenly and put it into a square mold;

[0054] (3) After the curd is put into the mold, put a small...

Embodiment 3

[0058] Ingredients used in this example: 50L of fresh horse milk, 1g of starter R-704, 0.7g of calf gastric rennet, frozen Monacus sp. GL-1, 1.5kg of salt, 20g of glucose, 2.5g of peptone , MgSO 4 0.25g, K 2 HPO 4 0.25g, rice cereal (30%w / v) 1000g.

[0059] (1) Filter 50L of fresh horse milk to remove impurities, sterilize at 75°C for 2 minutes, and then cool to 35°C to obtain processed milk. Inoculating starter R-704 into the treated milk, the inoculation amount is 1g / 50L, and culturing at a constant temperature of 28°C to a pH of 6.0, adding 0.7g calf gastric rennet, and curdling the milk for 30min to obtain curd;

[0060] (2) Cut the curd obtained in step (1) into blocks, stir for 10 minutes to drain the whey; after the whey is drained, add 3% salt to the curd, and the percentage is that the salt accounts for the curd. % by mass, stir evenly and put it into a square mold;

[0061] (3) After the curd is put into the mold, put a small bucket of water (about 1.0 kg) on ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com