Process For Making A Shelf-Stable Milk Based Beverage Concentrate

a technology of shelf-stable milk and concentrate, which is applied in the field of process for making shelf-stable milk beverages, can solve the problems of significant changes in the colligative properties of concentrate, and achieve the effects of reducing water activity of product, minimizing thermal damage, and minimizing thermal exposure of protein fractions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

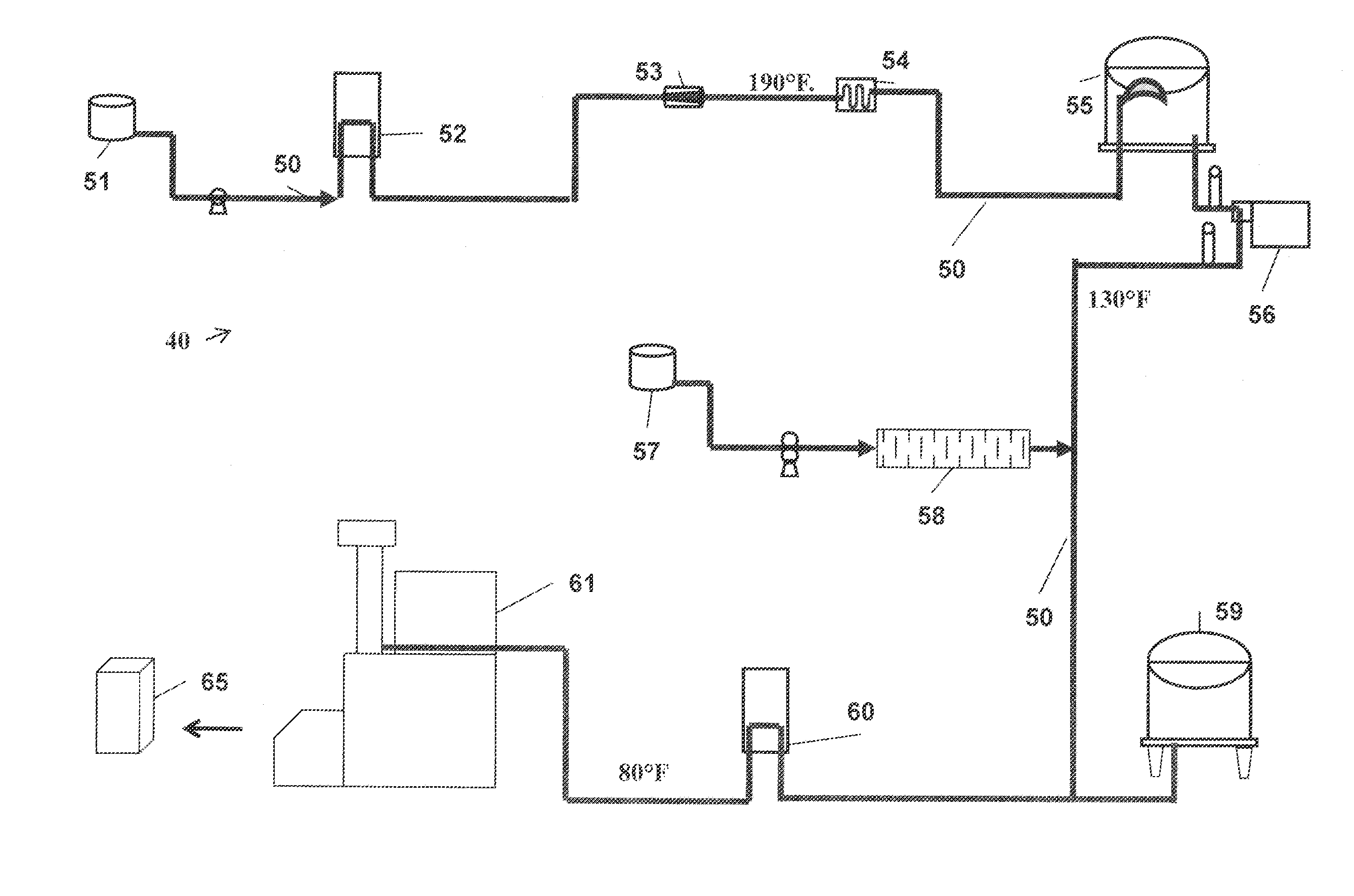

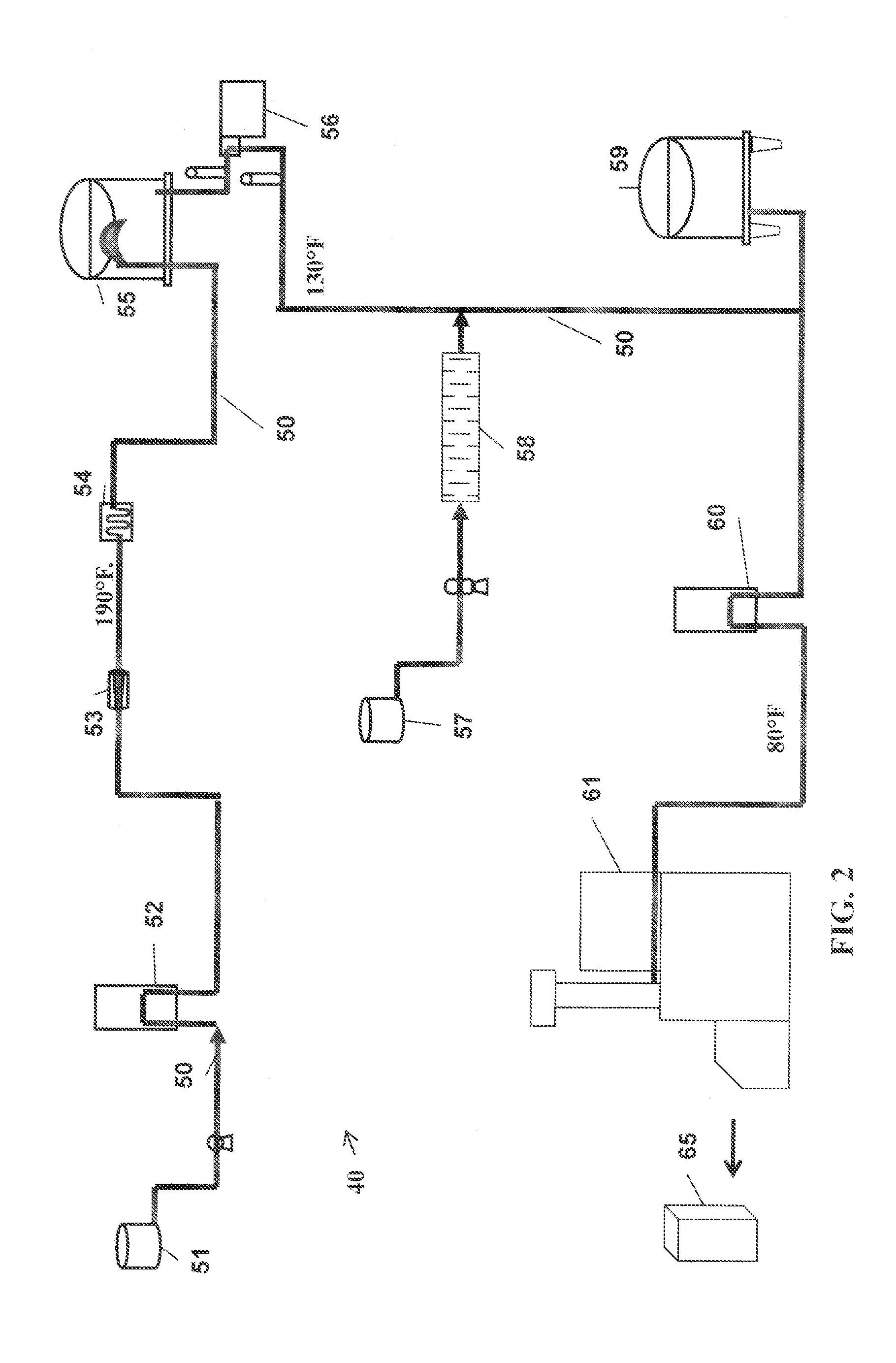

[0027]A process for preparing a shelf stable milk concentrate which can be reconstituted into a fresh tasting product is disclosed below.

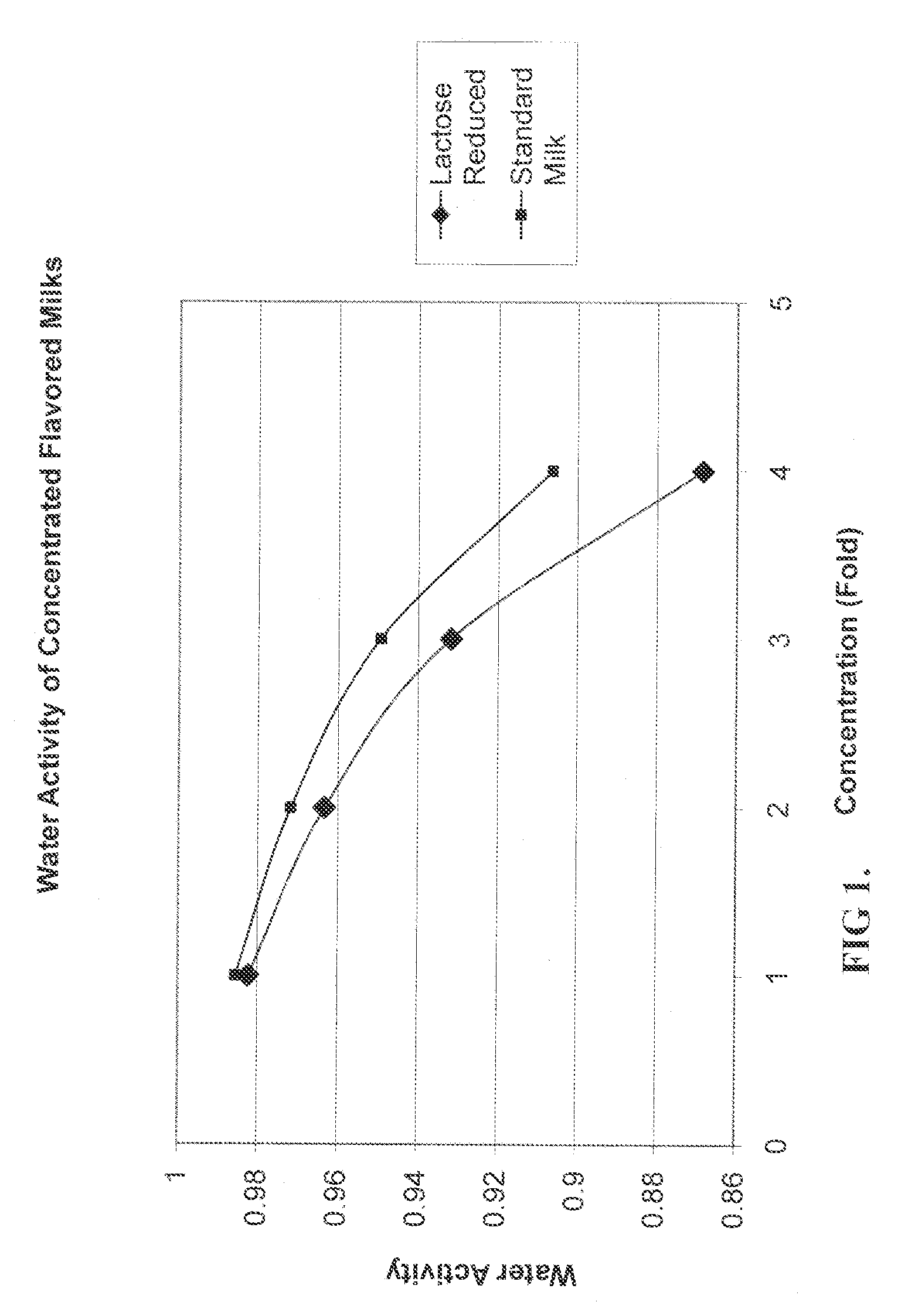

[0028]The product is preferably made from conventional condensed milk formulated with traditional amounts of stabilizers required to maintain the suspension of milk proteins without precipitation. Anhydrous sugars (sucrose, glucose or fructose) are preferably incorporated (at 0-40% weight) into the pasteurized 4× milk concentrate with agitation and shearing. The temperature during this step is elevated to 40-80° C. to aid in the solublization of the sugars. The formed syrup is preferably free of crystals to prevent future crystallization. The warm, sweetened milk concentrate is preferably introduced at a pre-determined temperature into a pre-sterilized vacuum chamber (500 mbar) to decrease the temperature and evaporate additional water using technology developed for UHT processing. The vacuum chamber is preferably continuously evacuated using an as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com