Nutritious powder for hypoglycemia patient

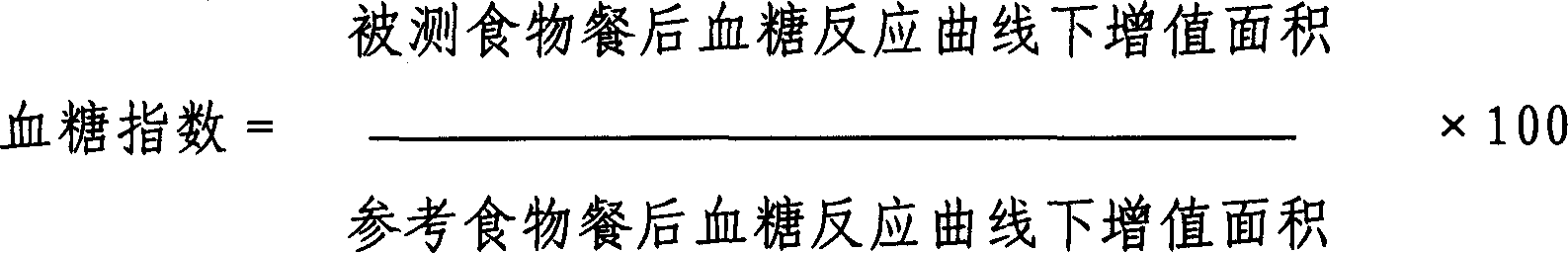

A nutritional powder, low blood sugar technology, applied in vegetable protein processing, food preparation, dairy products, etc., can solve problems such as unreported, and achieve the effects of high nutritional value, low glycemic index, and high sweetness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] It is made of fresh milk, sugar-free full-fat soybean powder, concentrated soybean protein, puffed lotus powder, isomalto-oligosaccharide (MD90), fructose, selenium-enriched yeast, resistant starch and soluble dietary fiber. After preparing raw materials, add lactase Hydrolyzed lactose, made by mixing various raw materials, sterilizing, concentrating, spray drying, cooling and sieving powder,

[0024] Wherein the weight proportion of each raw material is:

[0025] 300kg of fresh milk, 17kg of sugar-free full-fat soybean powder, 13kg of concentrated soybean protein, 12kg of puffed lotus powder, 7.5kg of isomaltooligosaccharide, 15kg of fructose, 0.5kg of selenium-enriched yeast, 5kg of resistant starch and soluble dietary fiber.

[0026] Prepare as follows:

[0027] a. Raw material preparation: pretreat the qualified raw milk, control the sucrose content of soybean powder and the protein content of soybean protein,

Embodiment 2

[0034] It is made of fresh milk, sugar-free full-fat soybean powder, concentrated soybean protein, puffed lotus powder, isomalto-oligosaccharide (MD90), fructose, selenium-enriched yeast, resistant starch and soluble dietary fiber. After preparing raw materials, add lactase Hydrolyzed lactose, made by mixing various raw materials, sterilizing, concentrating, spray drying, cooling and sieving powder,

[0035] Wherein the weight proportion of each raw material is:

[0036] 250kg of fresh milk, 23kg of sugar-free full-fat soybean powder, 15kg of concentrated soybean protein, 7.7kg of puffed lotus powder, 12kg of isomaltooligosaccharide, 13kg of fructose, 0.3kg of selenium-enriched yeast, 2kg of resistant starch and soluble dietary fiber.

[0037] Prepare as follows:

[0038] a. Raw material preparation: pretreat the qualified raw milk, control the sucrose content of soybean powder and the protein content of soybean protein,

[0039] b. Add lactase to hydrolyze lactose: add lact...

Embodiment 3

[0045] It is made of fresh milk, sugar-free full-fat soybean powder, concentrated soybean protein, puffed lotus powder, isomalto-oligosaccharide (MD90), fructose, selenium-enriched yeast, resistant starch and soluble dietary fiber. After preparing raw materials, add lactase Hydrolyzed lactose, made by mixing various raw materials, sterilizing, concentrating, spray drying, cooling and sieving powder,

[0046] Wherein the weight proportion of each raw material is:

[0047] 350kg of fresh milk, 20kg of sugar-free full-fat soybean powder, 8kg of concentrated soybean protein, 12kg of puffed lotus powder, 12kg of isomaltooligosaccharide, 9.7kg of fructose, 0.3kg of selenium-enriched yeast, 3kg of resistant starch and soluble dietary fiber.

[0048] Prepare as follows:

[0049] a. Raw material preparation: pretreat the qualified raw milk, control the sucrose content of soybean powder and the protein content of soybean protein,

[0050] b. Add lactase to hydrolyze lactose: add lactase...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com