Microecological preparation-tetragenous viable bacteria preparation and method for preparing same

A live bacteria preparation and live bacteria technology, applied in the field of micro-ecological preparations, can solve the problems of unsustainable effect and single effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

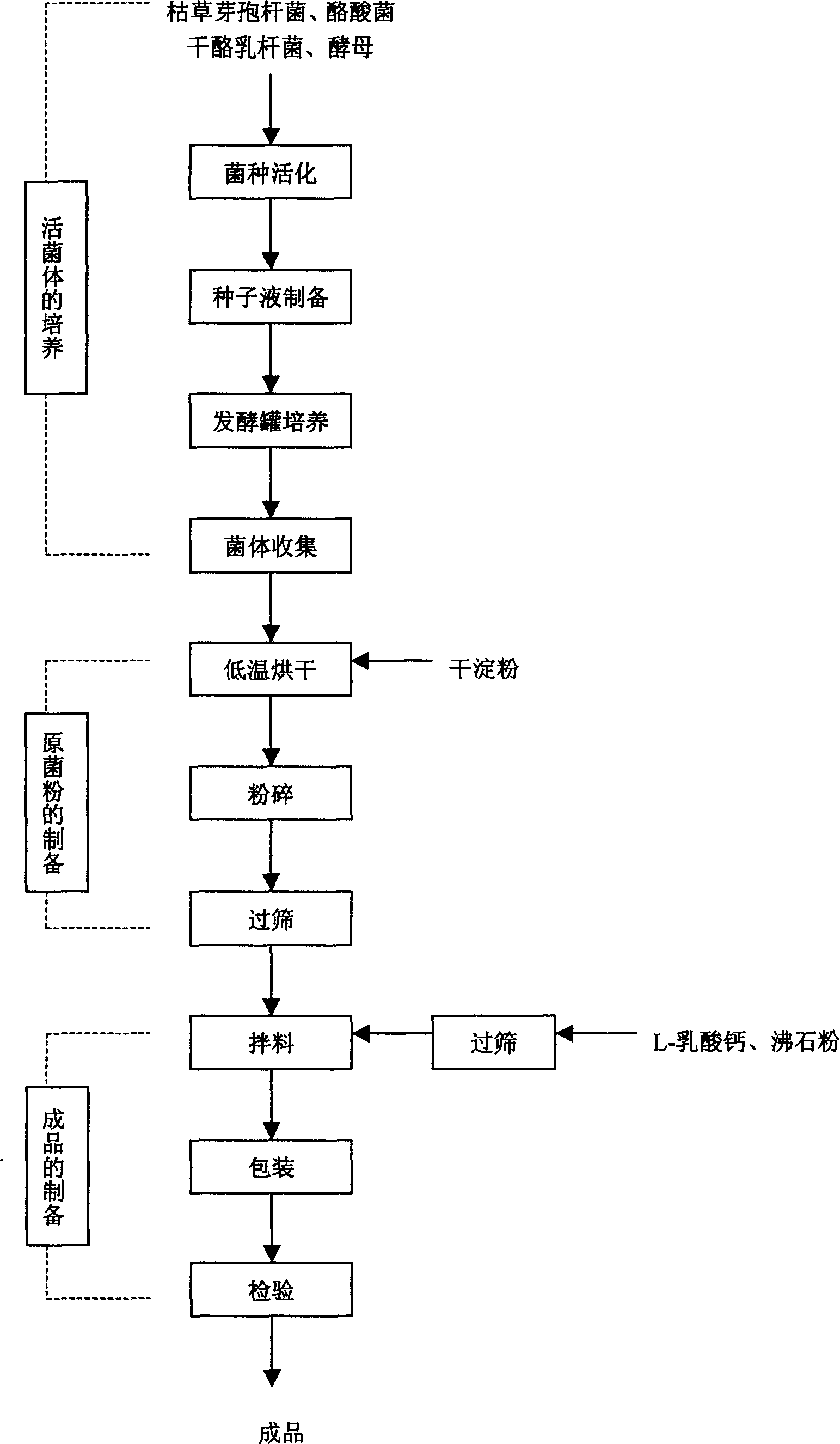

Method used

Image

Examples

Embodiment 1

[0116] Embodiment 1: the pure culture of living thalline

[0117] (1) Purebred culture of Bacillus subtilis CGMCC1.1414

[0118] Activation of strains

[0119] Aseptically open the freeze-dried strain of Bacillus subtilis, streak and inoculate on the slant of nutrient broth agar in the test tube, incubate at 37°C for 18-24h, then transfer to the slant of nutrient broth agar eggplant bottle, and incubate at 37°C for 20-24h , Microscopic examination, when more than 90% of the bacteria form spores, it is mature and ready to transplant.

[0120] seed culture

[0121] Prepare a sterile triangular flask with glass beads inside, scrape and wash the mature sludge on the slope of the eggplant bottle with sterile water, put it into the triangular flask, shake and disperse the sludge to obtain a uniform bacterial suspension. Heat the bacterial suspension in a water bath at 85°C for 5 minutes, and inoculate 0.1m with a volume ratio of 5%. 3 Seed cans. The filling factor of the seed ca...

Embodiment 2

[0156] Embodiment 2: the mixed culture of clostridium butyricum, Lactobacillus casei and yeast live thalline

[0157] Activation of strains

[0158] The activation of Clostridium butyricum, Lactobacillus casei, and saccharomyces freeze-dried strains is the same as described in Example 1.

[0159] seed culture

[0160] The seed culture of Clostridium butyricum, Lactobacillus casei, and saccharomyces is the same as described in Example 1.

[0161] fermenter culture

[0162] Inoculate the seed culture solution of Clostridium butyricum, Lactobacillus casei, and yeast at 6%, 12%, and 2% inoculation amounts into 1 m 3 Fermenter with a filling factor of 80% (v / v).

[0163] The medium composition of the fermenter is: brown sugar 20g, peptone 5g, yeast extract 3g, KH 2 PO 4 1g, (NH 4 ) 2 SO 4 2g, NaCl 3g, CaCO 3 3g, NaAc 3g, tap water 1000ml, pH 7.0, anaerobic culture at 35°C for 48h.

[0164] Cell collection

[0165] The culture solution is pumped into a continuous cent...

Embodiment 3

[0166] Embodiment 3: the preparation of the original bacterial powder of microbial pure strain

[0167] (1) Bacillus subtilis original bacteria powder

[0168] Mix the wet bacteria of Bacillus subtilis collected after pure breeding with dry starch at a mass ratio of 1:2, dry at 40-50°C for 20-24 hours at low temperature, pulverize with a pulverizer, pass through a 40-mesh sieve, and adjust with dry starch The total number of live bacteria of Bacillus subtilis in the original bacteria powder is ≥5×10 8 CFU / g.

[0169] (2) Clostridium butyricum original bacteria powder

[0170] Mix the wet bacteria of Clostridium butyricum collected after the pure culture with dry starch at a mass ratio of 1:2.5, dry at 40-50°C for 20-24 hours at low temperature, pulverize with a pulverizer, pass through a 40-mesh sieve, and use a dry The total number of live bacteria of Clostridium butyricum in the starch-adjusted original bacteria powder is ≥5×10 8 CFU / g.

[0171] (3) Lactobacillus casei ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com