Low-lactose liquid milk product containing fish oil and production method thereof

A low-lactose and dairy product technology, applied in dairy products, milk preparations, applications, etc., can solve problems that do not involve the concept of low-lactose, and achieve the effects of preventing cardiovascular diseases, meeting health needs, and improving nutritional levels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

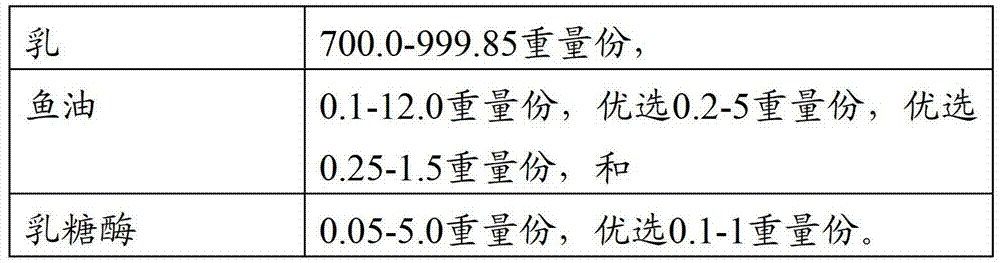

Method used

Image

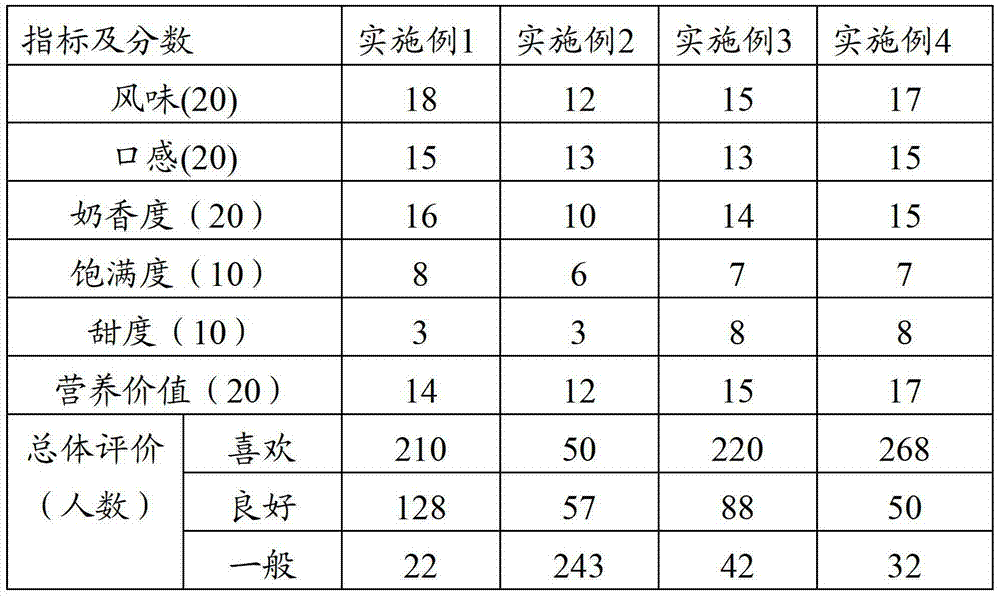

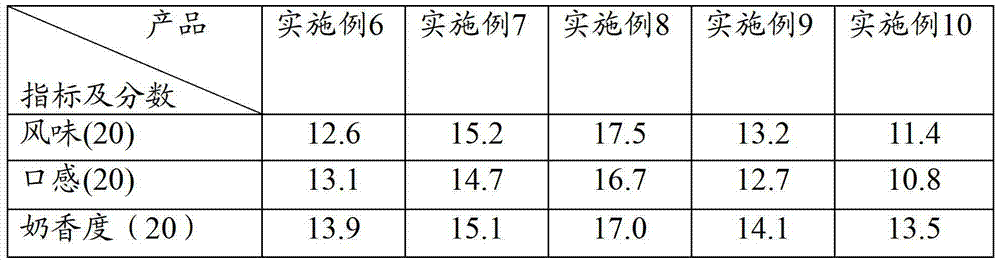

Examples

Embodiment 1

[0082] pure milk

[0083] The following formula (based on 1 ton):

[0084] Milk 1000kg

[0085] 1) Raw material requirements

[0086] Raw milk: sourced from self-owned pastures, in compliance with GB19301 regulations.

[0087] 2) raw milk inspection

[0088] Carry out inspections in accordance with relevant requirements and use them only after passing the test.

[0089] 3) Cooling and storage

[0090] Raw milk storage temperature is controlled at 0°C to 7°C.

[0091] 4) homogeneous

[0092] The homogenization temperature is 55°C-80°C, the total homogenization pressure is 150-170bar, the first-stage homogenization pressure is 120-150bar, and the second-stage homogenization pressure is 30-40bar.

[0093] Flash evaporation (or falling film evaporation)

[0094] The parameters of flash evaporation (or falling film evaporation) equipment are adjusted according to the physical and chemical indicators of the product.

[0095] 5) Pasteurization

[0096]85℃±2℃, the time is 15...

Embodiment 2

[0102] Liquid Dairy Products Containing Fish Oil

[0103] The following formula is preferred (based on 1 ton):

[0104] Milk 999kg

[0105] Fish oil 1kg

[0106] 1) Raw material requirements

[0107] Raw milk: sourced from self-owned pastures, in compliance with GB19301 regulations;

[0108] Fish oil: in line with the Ministry of Health's new resource food Ministry of Health of the People's Republic of China Announcement No. 18 in 2009.

[0109] 2) raw milk inspection

[0110] Carry out inspections in accordance with relevant requirements and use them only after passing the test.

[0111] 3) Cooling and storage

[0112] Raw milk storage temperature is controlled at 0°C to 7°C.

[0113] 4) Ingredients

[0114] Add the fish oil to the raw milk according to the recipe and stir well to combine.

[0115] 5) homogeneous

[0116] The homogenization temperature is 55°C-80°C, the total homogenization pressure is 150-170bar, the first-stage homogenization pressure is 120-150ba...

Embodiment 3

[0127] Low Lactose Liquid Dairy Products

[0128] The following formula is preferred (based on 1 ton):

[0129] Milk 999.8kg

[0130] Lactase 0.2kg

[0131] 1) Raw material requirements

[0132] Raw milk: sourced from self-owned pastures, in compliance with GB19301 regulations;

[0133] Lactase: in line with relevant regulations.

[0134] 2) raw milk inspection

[0135] Carry out inspections in accordance with relevant requirements and use them only after passing the test.

[0136] 3) Cooling and storage

[0137] Raw milk storage temperature is controlled at 0°C to 7°C.

[0138] 4) homogeneous

[0139] The homogenization temperature is 55°C-80°C, the total homogenization pressure is 150-170bar, the first-stage homogenization pressure is 120-150bar, and the second-stage homogenization pressure is 30-40bar.

[0140] Flash evaporation (or falling film evaporation)

[0141] The parameters of flash evaporation (or falling film evaporation) equipment are adjusted according...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com