Preparation method for low-lactose fermented dairy product

A technology for fermented dairy products and low lactose, applied in dairy products, milk preparations, applications, etc., can solve the problems of lack of taste and taste of fermented milk, and solve the problems of lactose intolerance, low lactose content and high viable count. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Example 1 A kind of preparation method of low-lactose fermented dairy product

[0043] The preparation method is to carry out the enzymatic hydrolysis of milk and fermentation at the same time, and carry out the following steps in sequence

[0044] ① Handling of raw milk

[0045] a1. Homogenization: Homogenize the raw milk, the homogenization temperature is 65°C, and the homogenization pressure is 25MPa to form the homogenized raw milk x;

[0046] b1. Pasteurization: pasteurize raw milk x at 95°C for 5 minutes to form pasteurized raw milk y;

[0047] ②Enzymatic hydrolysis and fermentation

[0048] a2. Cooling and cooling: cooling and cooling the pasteurized raw milk y;

[0049] b2. Enzymatic hydrolysis and fermentation: Add 500NLU / Kg of lactase to the raw milk cooled to room temperature for 42 ℃ enzymatic hydrolysis for 2 hours, and at the same time add Streptococcus thermophilus for 10 6 cfu / mL, 10 for Lactobacillus delbrueckii subsp bulgaricus 6 cfu / mL, 10 for L...

Embodiment

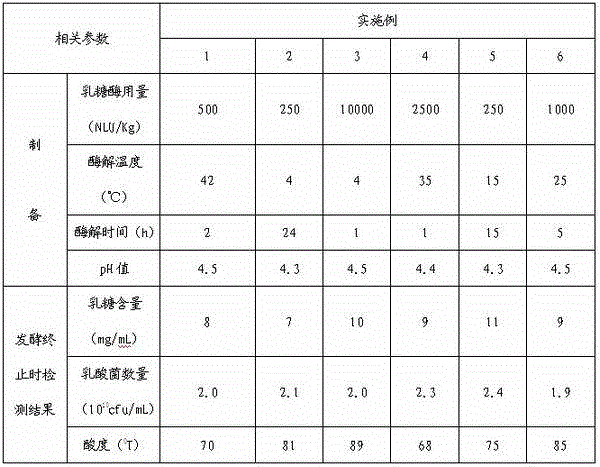

[0054] Example 2-6

[0055] Embodiments 2-6 are respectively a preparation method of a low-lactose fermented dairy product, and the preparation steps are similar to those of embodiment 1, except that the relevant parameters involved are different, as shown in the following table:

[0056]

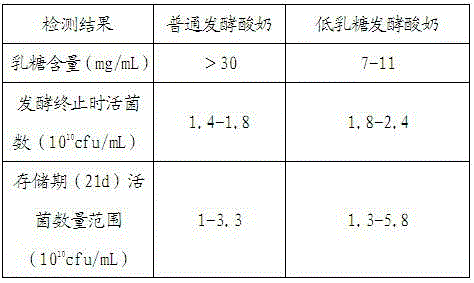

[0057] The product of the present invention reduces the content of lactose in milk by adding lactase, and not only makes the flavor and mouthfeel of the product more unique by inoculating a starter and fermenting, and the comparison data with ordinary fermented yogurt is shown in the following table:

[0058] As can be seen from the above table, compared with ordinary fermented yogurt, low lactose fermented yogurt has the following characteristics:

[0059] The lactose content was significantly reduced, and the number of viable bacteria at the end of fermentation was significantly higher than that of ordinary fermented yogurt. In addition, experiments have shown that the number of v...

Embodiment 7

[0060] Example 7 A preparation method of a low-lactose fermented dairy product,

[0061]The preparation method is to enzymatically hydrolyze the milk first and then ferment it, according to the following sequence of steps:

[0062] ① Handling of raw milk

[0063] A1. Homogenization: Homogenize the raw milk, the homogenization temperature is 65°C, and the homogenization pressure is 25MPa to form the homogenized raw milk x;

[0064] B1. Pasteurization: pasteurize the raw milk x at 95°C for 5 minutes to form pasteurized raw milk y;

[0065] ②Enzymolysis

[0066] A2. Cooling and cooling: cooling and cooling the pasteurized raw milk y;

[0067] B2. Enzymatic hydrolysis: add 1000NLU / Kg of lactase to the raw milk cooled to room temperature at 25°C for enzymatic hydrolysis for 5 hours;

[0068] C2. High temperature inactivation of enzymes: inactivation of enzymes at 95°C for 5 minutes to form dairy products n after enzymolysis;

[0069] ③Inoculation of starter

[0070] A3. Coo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com