Dense sandstone physical model and manufacture method thereof

A physical model and technology of tight sandstone, applied in the production of artificial tight sandstone physical model, the field of tight sandstone physical model, can solve problems such as difficulty in production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 1. Material selection

[0023] According to the specific requirements for making samples, the type of sand grains (such as quartz sand, feldspar and other natural sand) and grain size are first selected. For samples with larger porosity, sand grains with better particle sorting performance are selected. The scope increases, and the particles above 400 mesh are appropriately increased.

[0024] 2. Ratio of materials

[0025] In order to control the porosity of the sandstone sample within 30%, the content ratio of quartz sand, epoxy resin (model 618-2) and curing agent (model 593) is 6:1:20%.

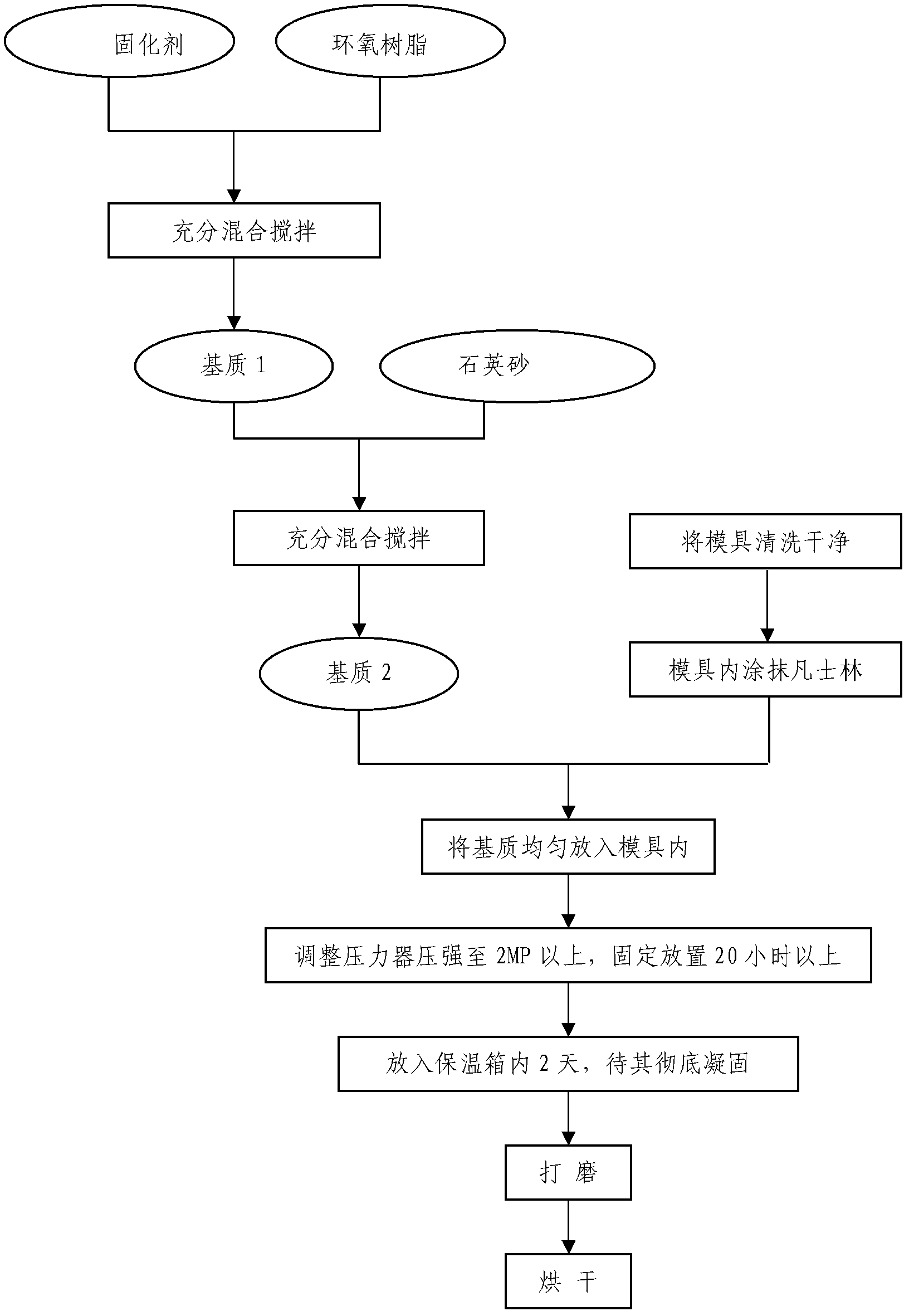

[0026] In this embodiment, the production method and process are introduced with 80 mesh quartz sand and a press with a pressure of 2MP. See figure 1 As shown, the specific operation is as follows:

[0027] Take a dry and clean bucket as a container, put it on the electronic scale, clear the data, put on gloves, take out the epoxy resin from the electronic incubator, weigh 100g...

Embodiment 2

[0035] Compared with Example 1 in this embodiment, three types of quartz sand, 80 mesh, 100 mesh and 120 mesh, are mixed together in a weight of about 1:1:1 to increase the variation. Epoxy resin (model 618-2) and quartz sand The ratio of sand is 1:10, and 20% curing agent (model 5784) of the mass of epoxy resin is added, and other preparation processes are the same as in Example 1. The tight sandstone physical model of this embodiment is obtained.

[0036] After testing, the density of the artificial sandstone in this embodiment is about 2.09g / cc; the porosity is about 20%; the longitudinal wave velocity is about 3580m / s. It is consistent with the actual sandstone formation parameters and meets the requirements of simulation experiments.

[0037] Using the tight sandstone of this embodiment to make a physical model, the first and third types of AVO phenomena can be successfully simulated.

Embodiment 3

[0039] Compared with Example 1 in this embodiment, quartz sand (containing a small amount of feldspar) selects 120 meshes, 200 meshes and 400 meshes and mixes them together according to the weight of about 1:2:4 to increase the variation. 618-2) with a ratio of 1:9 to quartz sand, and added a curing agent (model 593) of 25% of the mass of epoxy resin, the pressure machine pressure was 6MP, and it was fixed for more than 20 hours, and other preparation processes were the same as in the examples 1. The tight sandstone physical model of this embodiment is obtained.

[0040]After testing, the artificial sandstone of this embodiment has a density of about 2.30 g / cc; a porosity of about 16%; and a longitudinal wave velocity of about 4300 m / s. It is consistent with the actual sandstone formation parameters and meets the requirements of simulation experiments.

[0041] Using the tight sandstone of this embodiment to make a physical model, the first and third types of AVO phenomena c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com