Automatic-traveling grain turning over machine

A technology of automatic walking and grain machine, which is applied in the direction of drying and preserving seeds, can solve the problems of rising drying costs, increased energy consumption, unfavorable energy saving and consumption reduction, etc., and achieves low cost, improved energy saving and consumption reduction, and high work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

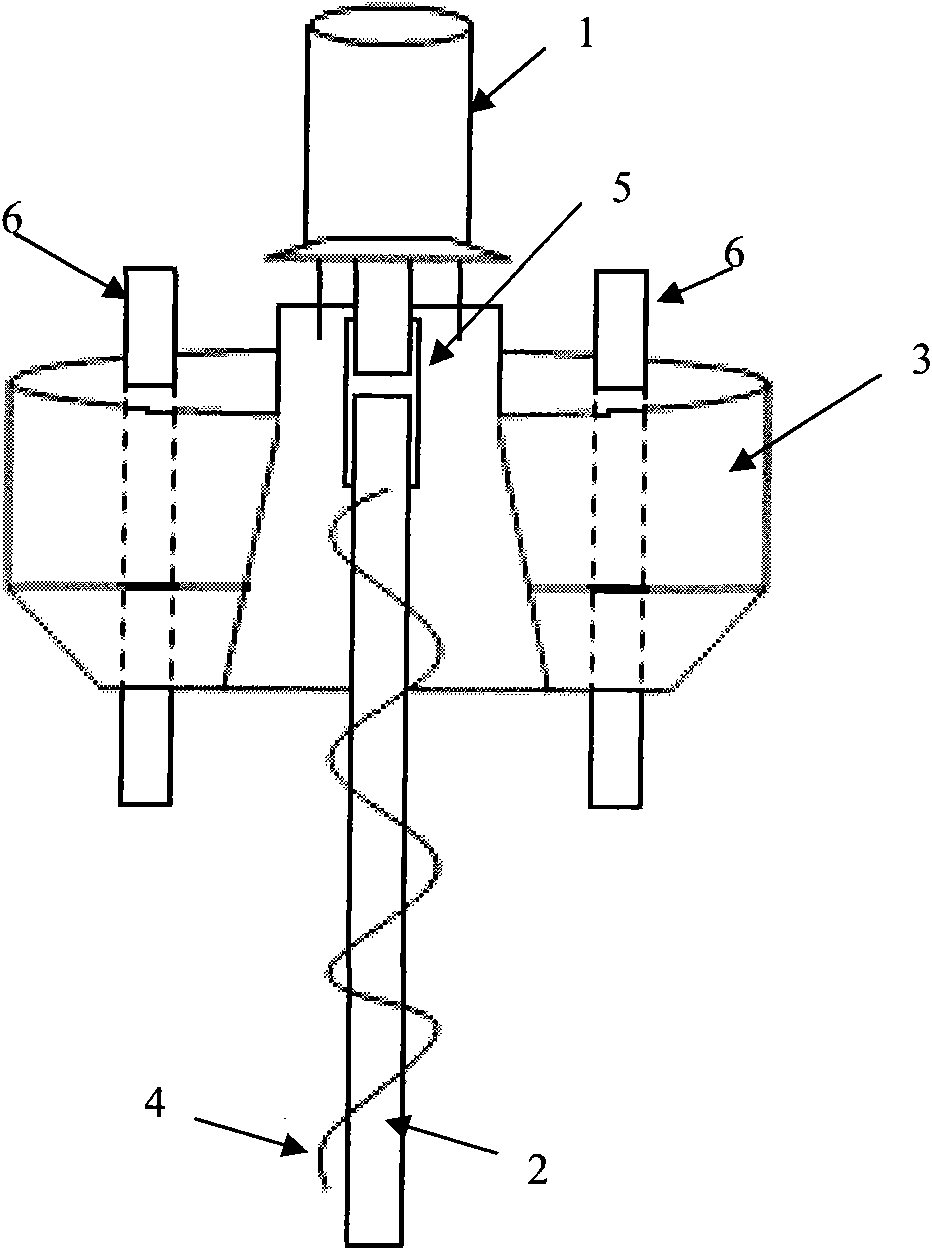

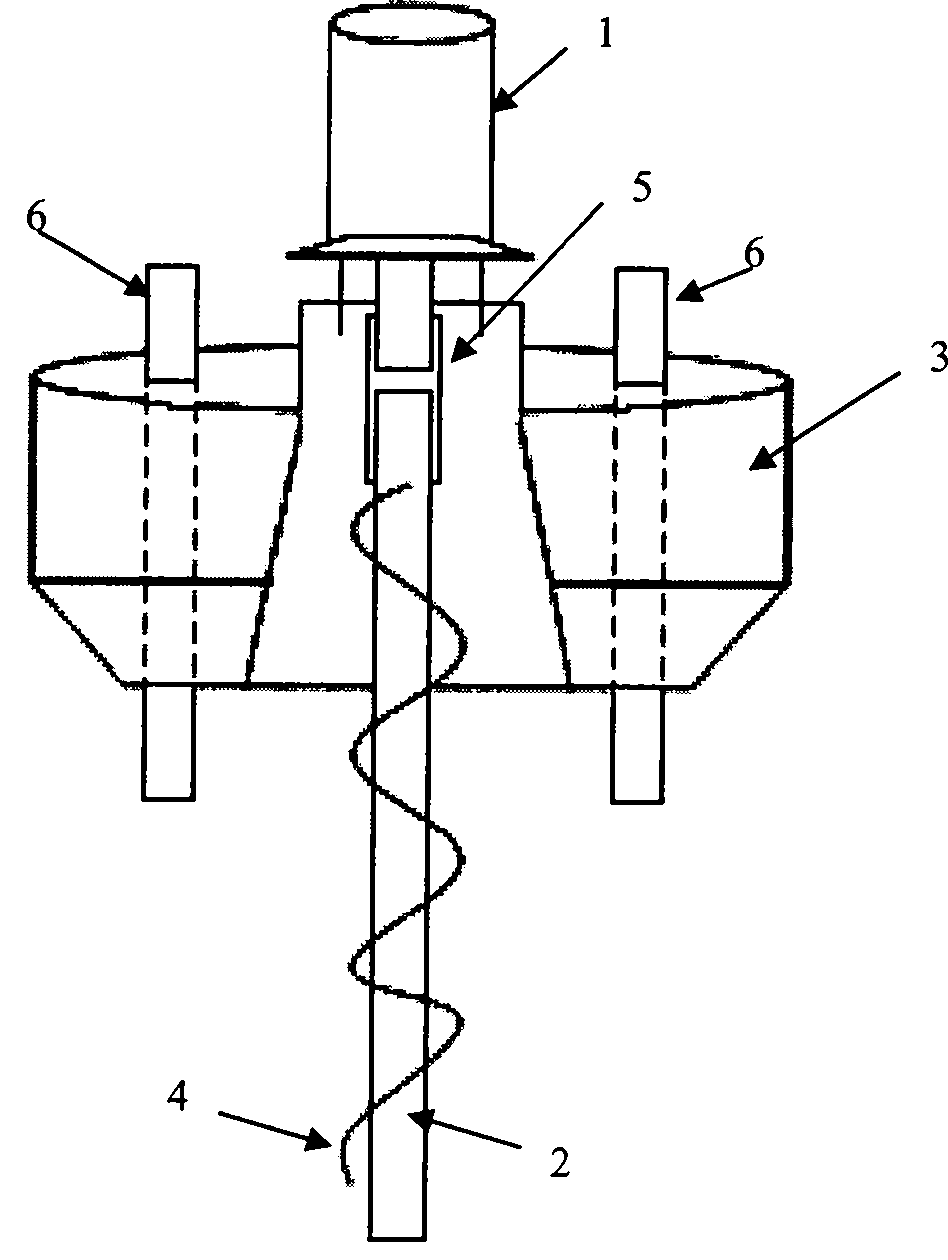

[0008] With reference to the accompanying drawings of the description, the automatic walking grain turning machine of the present invention is described in detail below.

[0009] The automatic walking grain turning machine of the present invention is mainly composed of 1 motor, 2 augers, 3 casings and the like. Motor power 2.2-4.5kw, speed 250-750RPM, box height 0.2m, auger shaft (screw) diameter D50-100mm, screw diameter (4) D200-240mm, screw length 1-5m, automatic walking grain turning machine The total weight is 38~50kg.

[0010] The motor and the auger are connected through a 5-coupling, and the motor and the box are connected through bearings. The bearing plays the role of fixing the motor shaft to avoid the shaking of the motor shaft and make the motor run stably.

[0011] First, the operator combines the appropriate length of the auger according to the thickness of the grain layer, places the grain turning machine above the grain layer and starts to turn the grain upw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com