Circular inflation modified atmosphere grain storage device and method using device

A system device and air-conditioning technology, which is applied in the ring-filled air-conditioning grain storage system device and the field of ring-filling air-conditioning grain storage, can solve the problems of high energy consumption, ineffective effect, and low efficiency, and achieve obvious insecticidal effect, The effect of saving nitrogen filling time and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

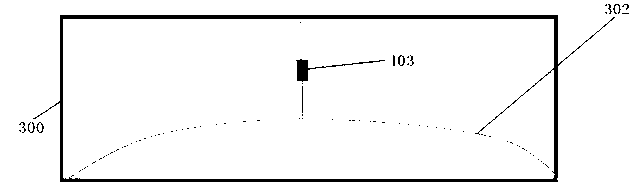

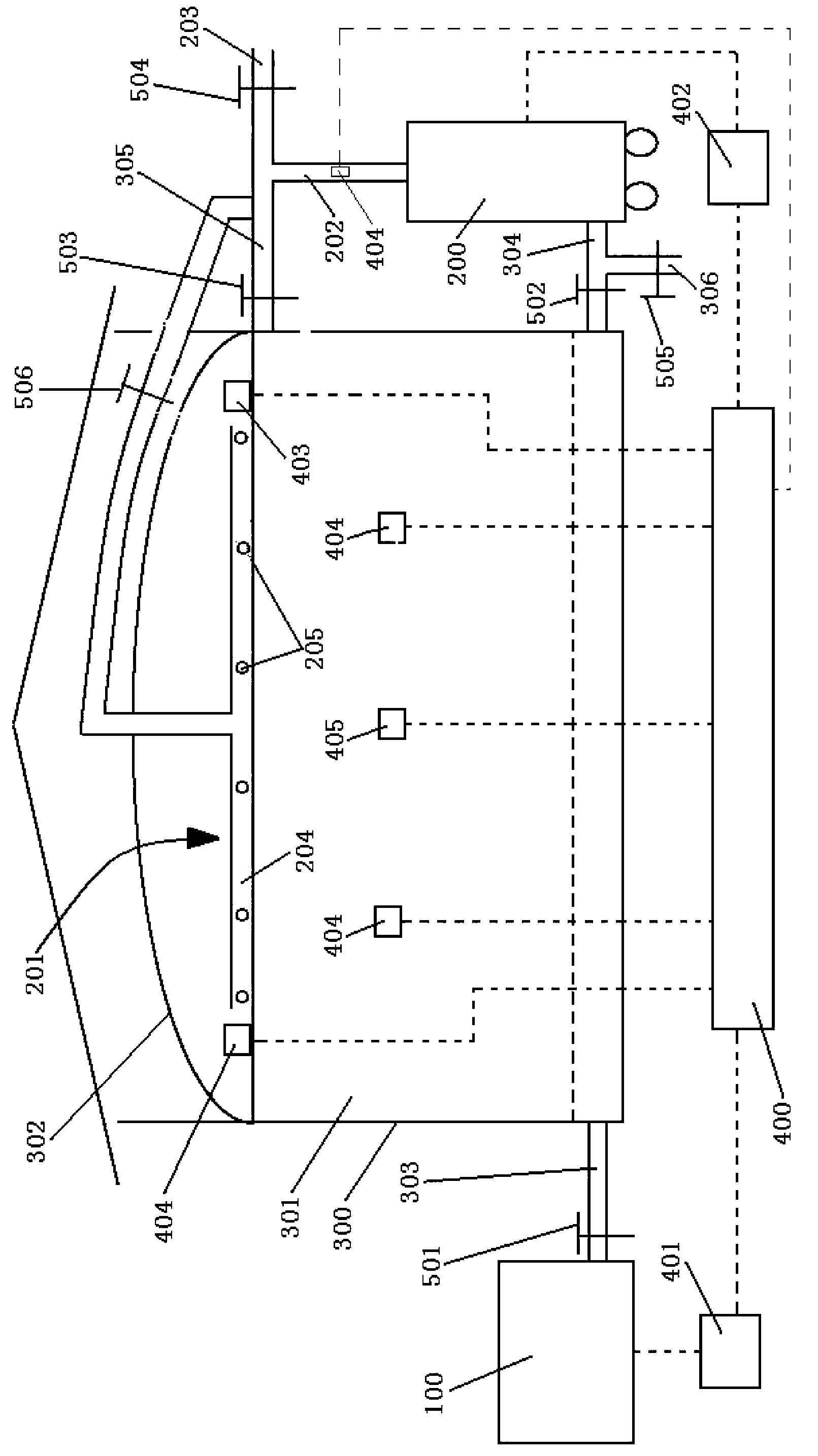

[0047] see figure 1 As shown, a ring-filled atmosphere-controlled grain storage system device of the present invention includes a nitrogen-filling system, a nitrogen-making circulation system, a granary system and an automatic control system;

[0048] see figure 1 As shown, the nitrogen filling system includes a nitrogen filling and nitrogen making unit 100; the nitrogen outlet end of the nitrogen filling and nitrogen making unit 100 is connected to the inlet of the grain storage ventilation duct of the granary through a nitrogen filling pipeline 303, and the nitrogen filling pipeline 303 is provided with an intake valve 501; the main function of the nitrogen filling system is to fill the closed granary with nitrogen;

[0049] see figure 1 As shown, the circulation system includes a nitrogen-making circulation unit 200 and a circulation pipeline; the circulation pipeline includes a suction pipeline 201 in the granary, a circulation main pipe 202 and a branch pipe 203 outside...

Embodiment 2

[0061] see Figure 5 As shown, embodiment 1 is repeated, the only difference is that the pressure sensor 403 is a rangefinder, and the rangefinder is arranged between the grain surface film airbag 302 and the top of the granary. The working principle is: use the distance between the top of the airbag 302 and the top of the granary to reflect the change of the pressure in the airbag; the distance meter is installed on the top of the granary to measure the distance between the highest part of the airbag and the top of the granary at any time. When the distance reaches the set value, It can be transmitted to the computer, analyze the situation, release information, and control the nitrogen-filling and nitrogen-generating unit and the nitrogen-generating circulation unit to implement the ring-filling and oxygen-reducing operation.

Embodiment 3

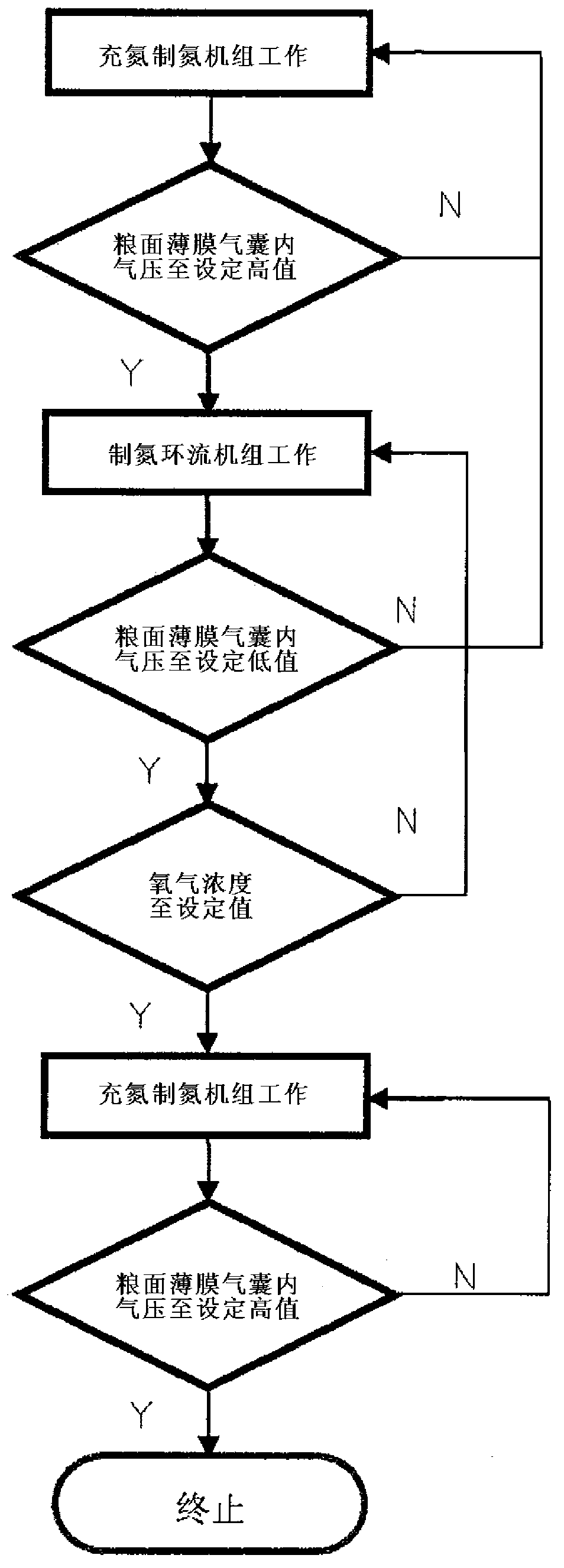

[0063] A method of using the ring-filled modified atmosphere grain storage system device of the above-mentioned embodiment 1 to carry out a method for ring-filled modified atmosphere grain storage, comprising the following steps:

[0064] 1) Start the nitrogen-filling and nitrogen-generating unit 100 through the nitrogen-filling and nitrogen-generating unit control module 401 of the automatic control system. At this time, valves 501, 503 and 504 are opened, valves 502 and 505 are closed, and the nitrogen gas of the nitrogen-charging and nitrogen-generating unit 100 enters the grain The grain storage ventilation duct in the pile fills the space between the grain surface film airbag 302 and the surface of the grain pile 301 with nitrogen to reduce oxygen; fill the nitrogen until the nitrogen concentration in the air outlet pipe 305 is ≥ 85% by volume, and then close the nitrogen-filling and nitrogen-generating unit 100; preferably, the pressure in the grain surface film airbag 30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com