Short technological process of preparing metal grains

A metal particle and short-process technology, which is applied in the field of short-process preparation of metal tin particles, can solve the problems of pollution of finished metal particles, low yield of metal particles, high investment in equipment construction, and achieve no slag inclusion size, simple equipment, The effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

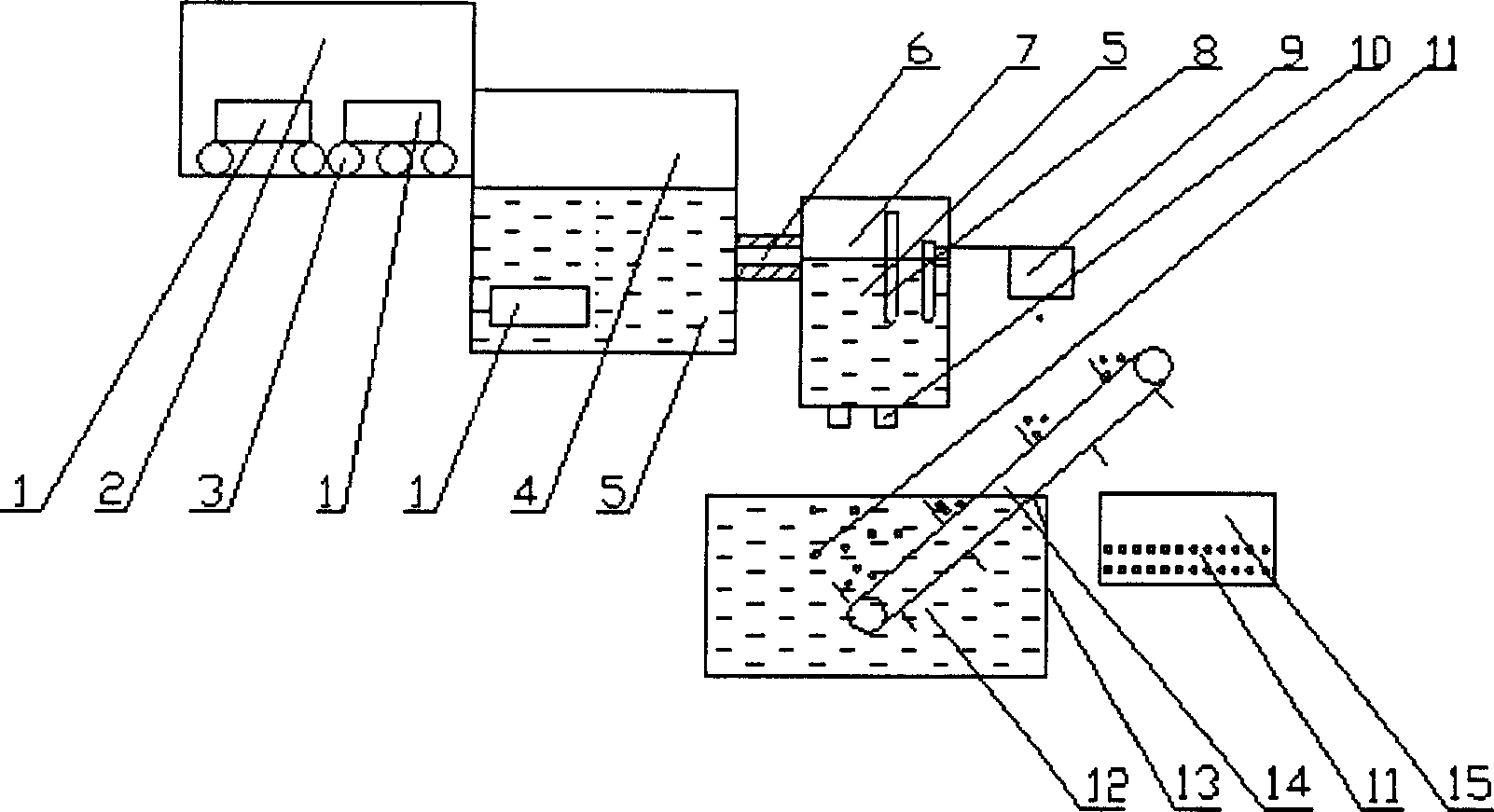

[0033] Firstly, the metal zinc ingot 1 is placed on the roller table 3 of the preheating chamber 2 for preheating treatment. After the preheating treatment, the temperature of the metal zinc ingot 1 reaches 118° C., and the zinc ingot is preheated by an electric furnace. After the zinc ingot is preheated, it directly enters the melting furnace 4. The melting furnace 4 uses resistance heating, and the temperature in the melting furnace is controlled at 22° C. above the melting point of the metal. After the zinc ingot is melted into molten zinc 5, the molten metal 5 is transported to the holding furnace 7 by using a Φ120mm ceramic tube 6, and the ceramic tube 6 is made of Si 3 N 4 Add 22% ZrO to the ceramic 2 and 14% columnar β-Si 3 N 4 phase and then sintered. The holding furnace 7 uses a ceramic inner heating sleeve 8 for heating, uses a thermocouple with an accuracy greater than 1.5°C to measure the temperature of the molten metal in the holding furnace 7, and uses a temp...

Embodiment 2

[0035] Firstly, the metal tin ingot 1 is placed on the roller table 3 of the preheating chamber 2 for preheating treatment. After the preheating treatment, the temperature of the metal tin ingot 1 reaches 107° C., and the tin ingot is preheated by an electric furnace. After the tin ingot is preheated, it directly enters the melting furnace 4. The melting furnace 4 uses resistance heating, and the temperature in the melting furnace is controlled at 18° C. above the melting point of the metal. After the tin ingot is melted into molten tin 5, the molten metal 5 is transported to the holding furnace 7 by using a Φ100mm ceramic tube 6, and the ceramic tube 6 is made of Si 3 N 4 Add 19% ZrO to the ceramic 2 and 15% columnar β-Si 3 N 4 phase and then sintered. A ceramic heating sleeve 8 is used for heating in the holding furnace 7, and a thermocouple with an accuracy greater than 1.5°C is used to measure the temperature of the molten metal 5 in the holding furnace 7, and a temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com