Preparation method of large-grained iodide perovskite thin film

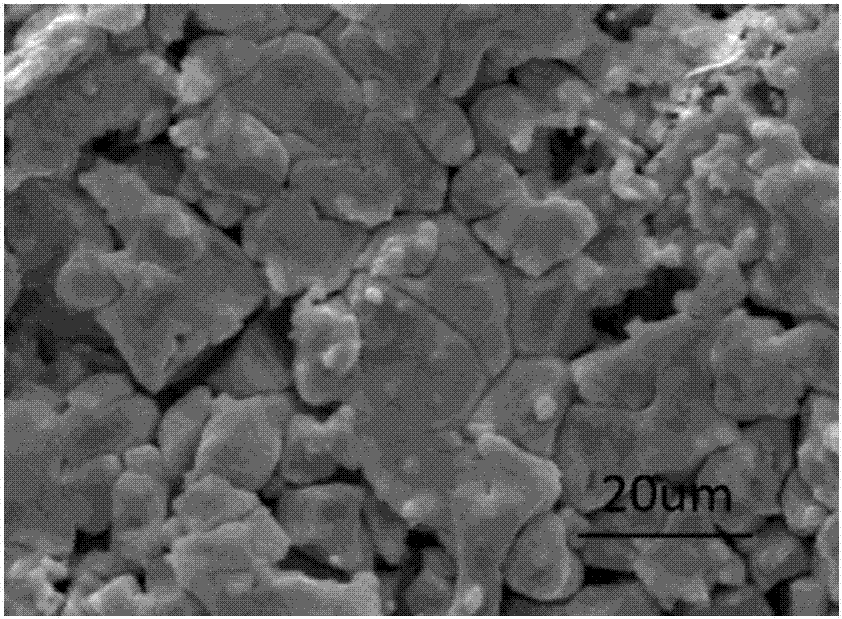

An iodide and perovskite technology is applied in the field of preparation of large-grain iodide perovskite thin films, which can solve the problems of small grain size and poor grain uniformity of perovskite thin films, and achieve large grain size. , The film thickness is easy to control, and the grain size uniformity is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

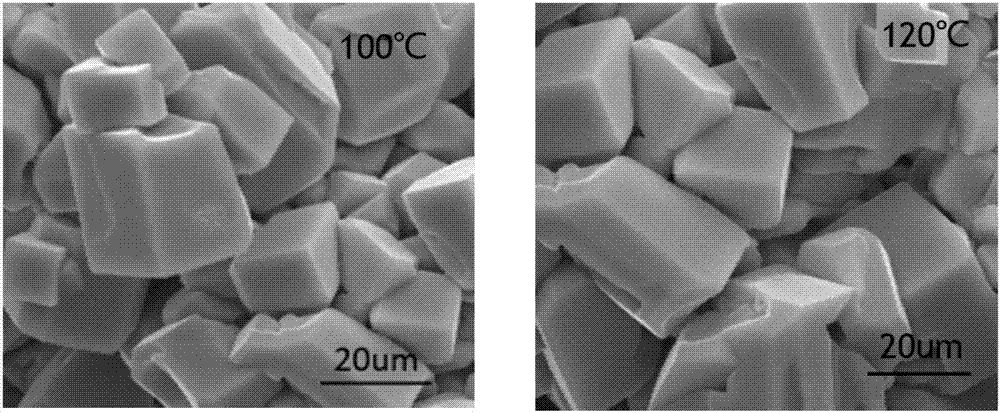

[0023] (1) Change CH 3 NH 3 I and PbI 2 After mixing in equal molar amounts, methanol was added, and the reaction was sonicated for 30 minutes to obtain yellow methylamine lead iodide precipitate. Remove the supernatant, heat the yellow precipitate at 100-120°C to remove excess methanol, and grind the dried powder under nitrogen protection to obtain methylamine lead iodide perovskite particles. Disperse the perovskite particles in the pine In oleyl alcohol, a precursor solution with a concentration of 1 mol / L is obtained.

[0024] (2) Spin-coating the dense layer and the porous layer on the cleaned FTO glass sheet surface respectively. The spin-coating conditions are low speed 1000rpm for 10s, then high speed 5000rpm for 40s, then annealing treatment, the treatment temperature is 100℃, and the time is 1h .

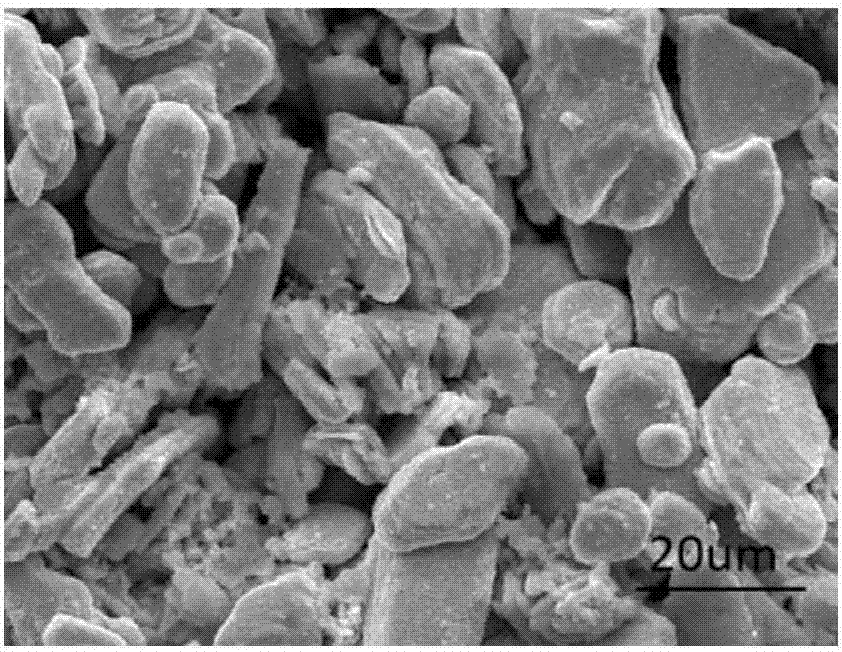

[0025] (3) The precursor solution was spin-coated on the FTO glass base layer under the conditions of low-speed 1000rpm for 10s, high-speed 6000rmp for 35s, and then annealed ...

Embodiment 2

[0027] (1) Change CH 3 NH 3 I and PbI 2 After mixing in equal molar amounts, methanol was added, and the reaction was sonicated for 30 minutes to obtain yellow methylamine lead iodide precipitate. Remove the supernatant, heat the yellow precipitate at 100-120°C to remove excess methanol, and grind the dried powder under nitrogen protection to obtain methylamine lead iodide perovskite particles. Disperse the perovskite particles in the pine In oleyl alcohol, a precursor solution with a concentration of 1 mol / L is obtained.

[0028] (2) Spin-coating the dense layer and the porous layer on the cleaned FTO glass sheet surface respectively. The spin-coating conditions are low speed 1000rpm for 10s, then high speed 5000rpm for 40s, then annealing treatment at 100°C for 1h.

[0029] (3) Spin-coating the precursor solution onto the FTO glass base layer under the conditions of low-speed 1000rpm for 10s, high-speed 6000rmp for 35s, and then annealed at 120℃ to remove excess solvent to obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com