Film-expanding grain-eliminating method of wafer and wafer production method

A technology of wafers and grains, which is applied in the manufacture of electrical components, electrical solid devices, semiconductor/solid devices, etc., can solve problems such as low packaging efficiency, chipping of adjacent grains, and affecting the normal progress of the process, so as to improve The effect of packaging efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

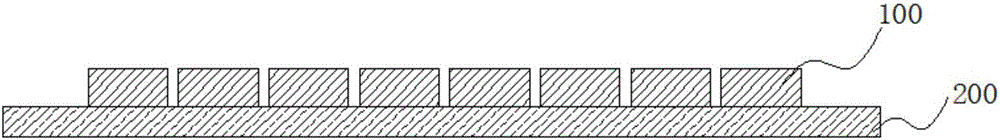

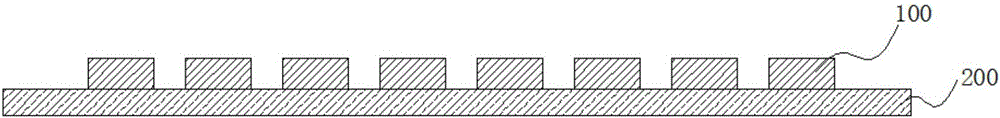

[0065] figure 1 A schematic diagram of the cross-sectional structure of the wafer before film expansion provided in Embodiment 1 of the present invention; figure 2 for figure 1 The schematic diagram of the cross-sectional structure of the wafer after film expansion is shown; figure 1 with figure 2 As shown, the embodiment of the present invention provides a wafer film expansion and particle extraction process, including the following steps:

[0066] (a) providing a wafer, the wafer is cut into a plurality of crystal grains 100, the multiple crystal grains 100 are adhered to the base film 200, the distance between the crystal grains 100 is 200 μm, and the base film 200 is fixed on the fixing ring, And the crystal grain 100 has passed the electrical performance test, and the unqualified grain is marked as black;

[0067] (b) Heat the stage of the film expander to 50°C, put the bottom film 200 with the crystal grains 100 attached on the stage of the film expander, fix the b...

Embodiment 2

[0074] The embodiment of the present invention provides a wafer production method. The unqualified crystal grains are removed by adopting the film expansion method provided by the embodiment of the present invention, so that there is no need to separate the grains during the subsequent packaging process. It only needs to be packaged directly, which effectively reduces the operation steps of the packaging process and improves the packaging efficiency.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com