A kind of environment-friendly biocompatible porous film and preparation method thereof

A biocompatible, porous membrane technology, applied in the field of membrane materials, can solve the problems of poor recyclability, reduced performance, material waste, etc., and achieve the effects of high recyclability, stable performance and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

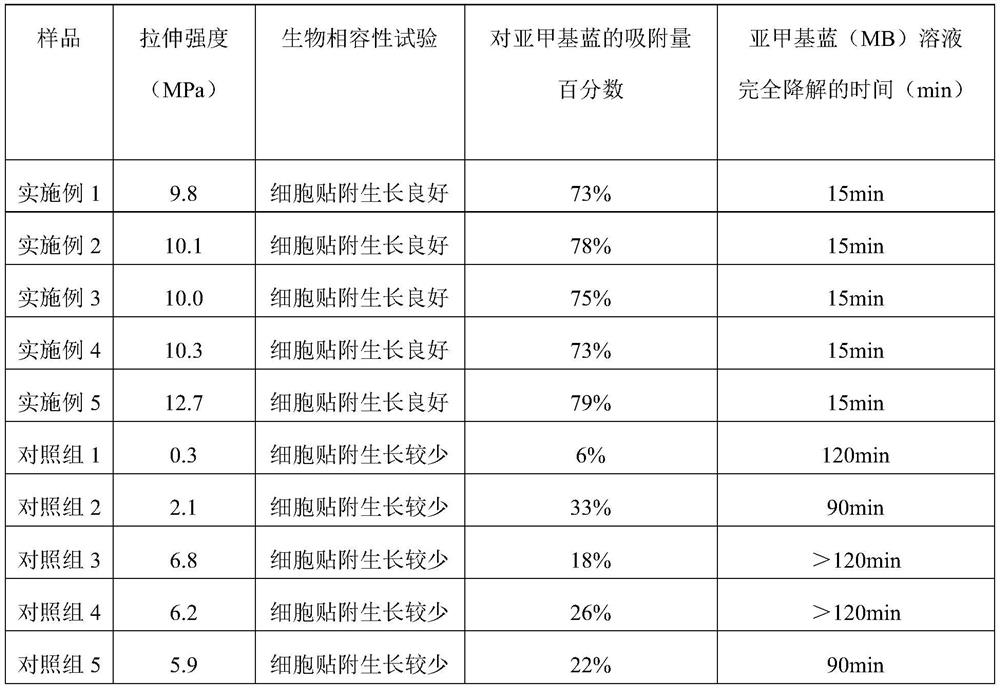

Examples

Embodiment 1

[0026] Prepare an environmentally friendly biocompatible porous membrane, comprising the following steps:

[0027] (1) Weigh 80 parts of polylactic acid, 10 parts of acrylic acid, 2 parts of dibenzoyl peroxide, 50 parts of titanium dioxide powder, 10 parts of tourmaline powder, 5 parts of tricalcium phosphate, porogen chlorination Potassium 20 parts. The molecular weight of polylactic acid is 50,000; the particle size of tricalcium phosphate is ultrafine tricalcium phosphate of 2 to 3 μm; the particle size of tourmaline powder is 50nm; the particle size of titanium dioxide powder is 5nm.

[0028] (2) Add the polylactic acid weighed in step (1) into 240 parts of organic solvent tetrahydrofuran, and at the same time pass through nitrogen gas and stir, then heat to 60°C and reflux for 2 hours to dissolve, and obtain solution I.

[0029] (3) Add the acrylic acid and dibenzoyl peroxide weighed in the step (1) to the solution I prepared in the step (2) at the same time, and carry o...

Embodiment 2

[0033] Prepare an environmentally friendly biocompatible porous membrane, comprising the following steps:

[0034] (1) Weigh 100 parts of polylactic acid, 50 parts of acrylic acid, 10 parts of dibenzoyl peroxide, 100 parts of titanium dioxide powder, 30 parts of tourmaline powder, 20 parts of tricalcium phosphate, and 50 parts of porogen sucrose according to the required parts by weight. share. The molecular weight of polylactic acid is 200,000; the particle size of tricalcium phosphate is ultrafine tricalcium phosphate of 2 to 3 μm; the particle size of tourmaline powder is 2000nm; the particle size of titanium dioxide powder is 100nm.

[0035] (2) Add the polylactic acid weighed in step (1) into 200 parts of organic solvent dichloromethane, and at the same time pass in nitrogen gas and stir, and then heat to 80° C. and reflux for 6 hours to dissolve to obtain solution I.

[0036] (3) Add the acrylic acid and dibenzoyl peroxide weighed in the step (1) to the solution I prepa...

Embodiment 3

[0040] Prepare an environmentally friendly biocompatible porous membrane, comprising the following steps:

[0041] (1) Weigh 85 parts of polylactic acid, 20 parts of acrylic acid, 4 parts of dibenzoyl peroxide, 60 parts of titanium dioxide powder, 12 parts of tourmaline powder, 12 parts of tricalcium phosphate, and porogen alginic acid according to the required parts by weight. Sodium 25 parts. The molecular weight of polylactic acid is 80,000; the particle size of tricalcium phosphate is ultrafine tricalcium phosphate of 2-3 μm; the particle size of tourmaline powder is 100nm; the particle size of titanium dioxide powder is 30nm.

[0042](2) Add the polylactic acid weighed in step (1) into 170 parts of organic solvent tetrahydrofuran, and at the same time pass through nitrogen and stir, and then heat to 65 ° C and reflux for 3 hours to dissolve to obtain solution I.

[0043] (3) Add the acrylic acid and dibenzoyl peroxide weighed in the step (1) to the solution I prepared in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com