Copper-doped Fe3O4 magnetic composite nanomaterial as well as preparation method and application thereof

A magnetic composite nanometer, copper-doped technology, applied in chemical instruments and methods, water/sludge/sewage treatment, metal/metal oxide/metal hydroxide catalysts, etc. It can achieve the effect of strong catalytic degradation ability at room temperature, simple raw materials, and favorable mass production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A copper-doped Fe 3 o 4 A preparation method for a magnetic composite nanomaterial, comprising the following steps:

[0035] Heat and stir 20mmol choline chloride and 40mmol urea at 50°C to prepare an ionic deep eutectic solvent; add 3mmol FeSO to the resulting ionic deep eutectic solvent 4 ·7H 2 O and 5.2mmolKOH, stir evenly to obtain a mixed solution, and continue to add 3.75mmolKOH and 0.15mmolCuCl to the resulting mixed solution 2 2H 2O, continue stirring evenly to obtain a reaction solution; place the obtained reaction solution in an oven at 110°C for 4 hours, anneal and cool, collect the obtained solid particles by magnetic separation, and finally wash and dry to obtain the final product.

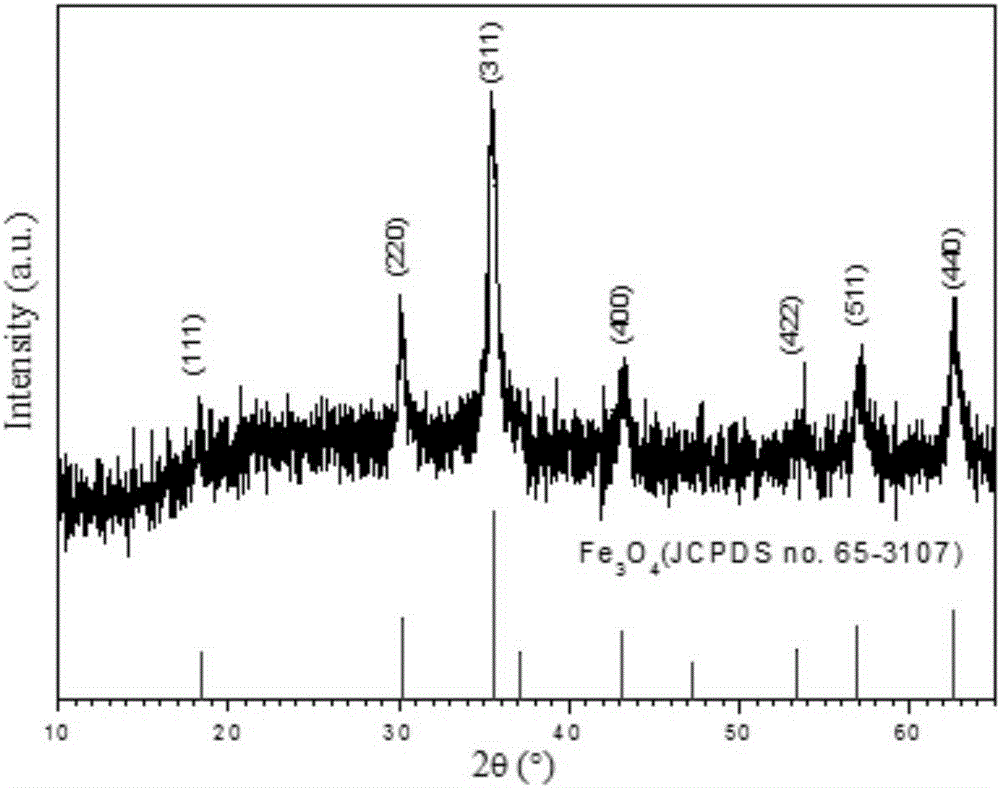

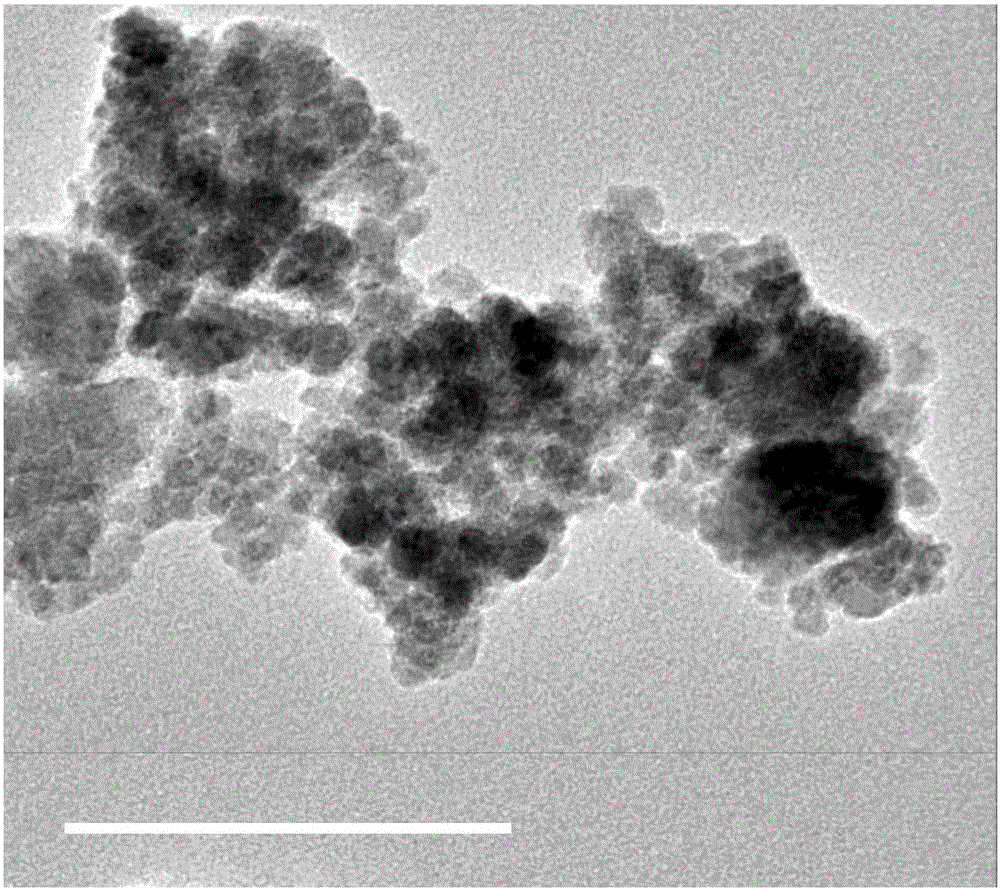

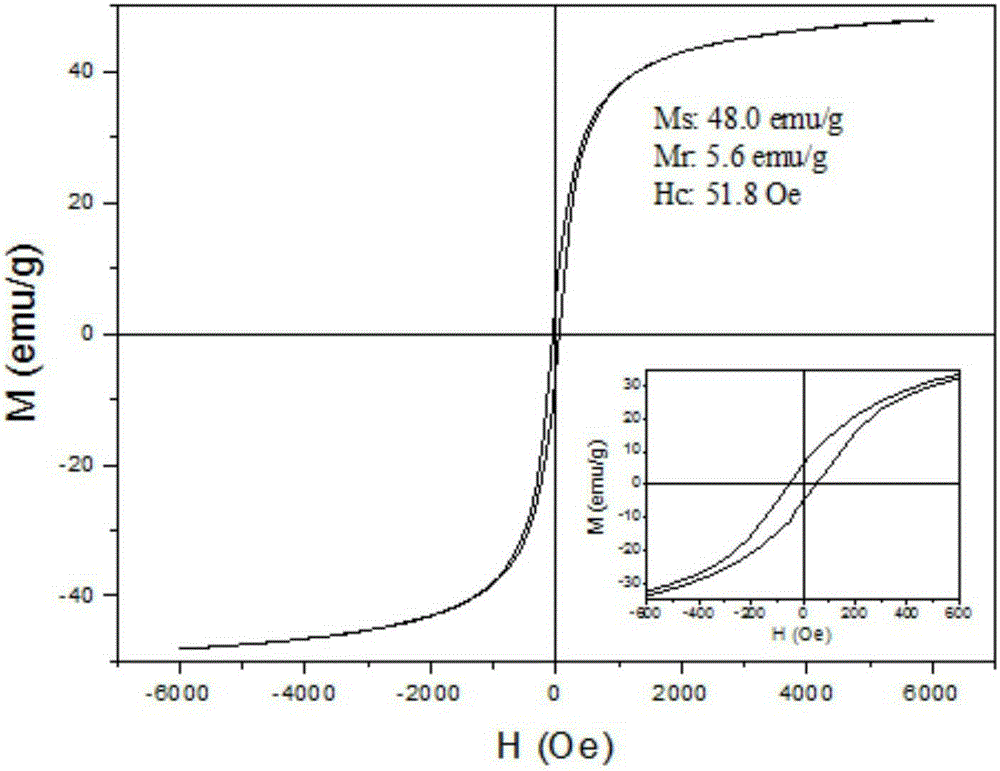

[0036] The X-ray diffraction analysis result of the product obtained in this embodiment is shown in figure 1 , figure 1 The characteristic peaks in the Fe 3 o 4 The standard collection of illustrative plates is consistent (JCPDSNo.65-3107), shows that the product partic...

Embodiment 2

[0046] A copper-doped Fe 3 o 4 A preparation method for a magnetic composite nanomaterial, comprising the following steps:

[0047] Heat and stir 20mmol choline chloride and 40mmol urea at a temperature of 50°C to obtain an ionic deep eutectic solvent; add 6mmol FeSO to the obtained ionic deep eutectic solvent 4 ·7H 2 O and 10.4mmolKOH, stir evenly to obtain a mixed solution, and continue to add 7.5mmolKOH and 0.15mmolCuCl to the resulting mixed solution 2 2H 2 O, continue to stir evenly to obtain a reaction solution; place the obtained reaction solution in an oven at 110°C for 4 hours, anneal and cool, and magnetically separate and collect the resulting solid particles, and finally wash and dry to obtain the copper-doped Fe 3 o 4 Magnetic composite nanomaterials.

Embodiment 3

[0049] A copper-doped Fe 3 o 4 A preparation method for a magnetic composite nanomaterial, comprising the following steps:

[0050] Heat and stir 20mmol choline chloride and 40mmol urea at a temperature of 50°C to obtain an ionic deep eutectic solvent; add 0.8mmol FeSO to the obtained ionic deep eutectic solvent 4 ·7H 2 O and 1mmolKOH, stir evenly to obtain a mixed solution, continue to add 1.4mmolKOH and 0.08mmolCuCl to the resulting mixed solution 2 2H 2 O, continue to stir evenly to obtain a reaction solution; place the obtained reaction solution in an oven at 110°C for 6 hours, anneal and cool, and magnetically separate and collect the resulting solid particles, and finally wash and dry to obtain the copper-doped Fe 3 o 4 Magnetic composite nanomaterials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Saturation magnetization | aaaaa | aaaaa |

| Remanence | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com