Preparation method of lignocellulose nanofibers

A technology of lignocellulose and nanofibers, which is applied in fiber raw material processing, textiles and papermaking, etc., can solve the problems of harsh preparation process conditions, poor interface compatibility, and poor product quality, and achieve uniform particle size distribution, interfacial phase Good capacity and improved dispersion stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

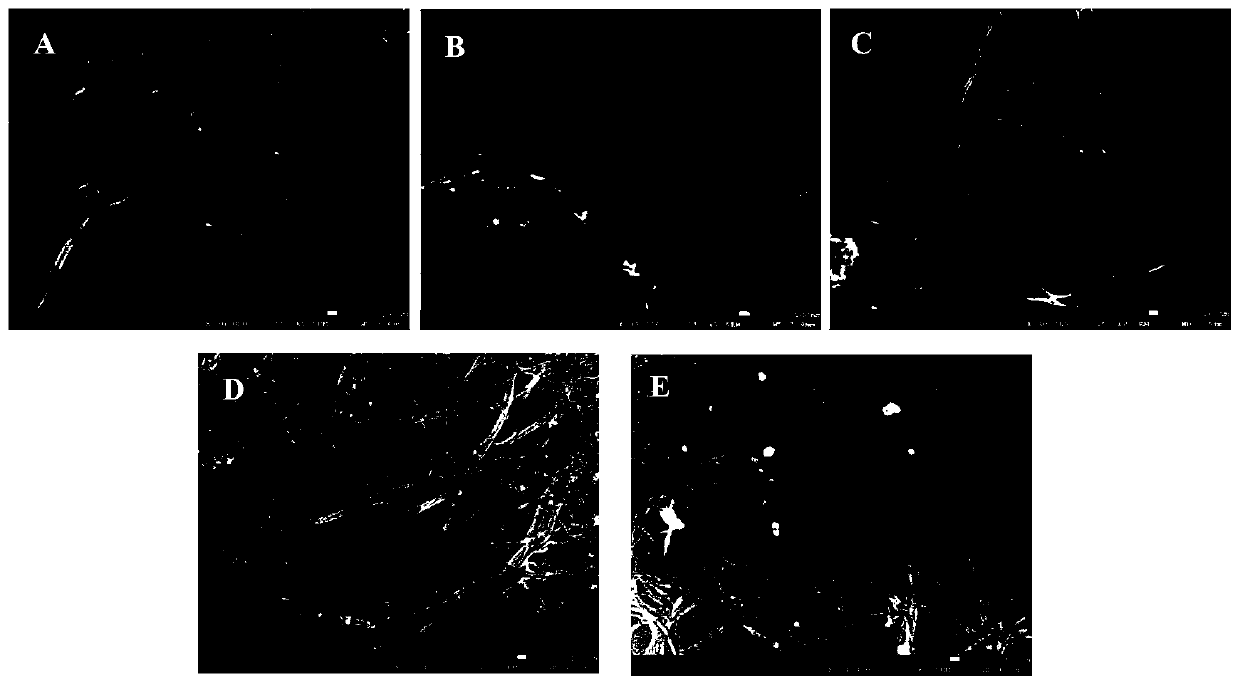

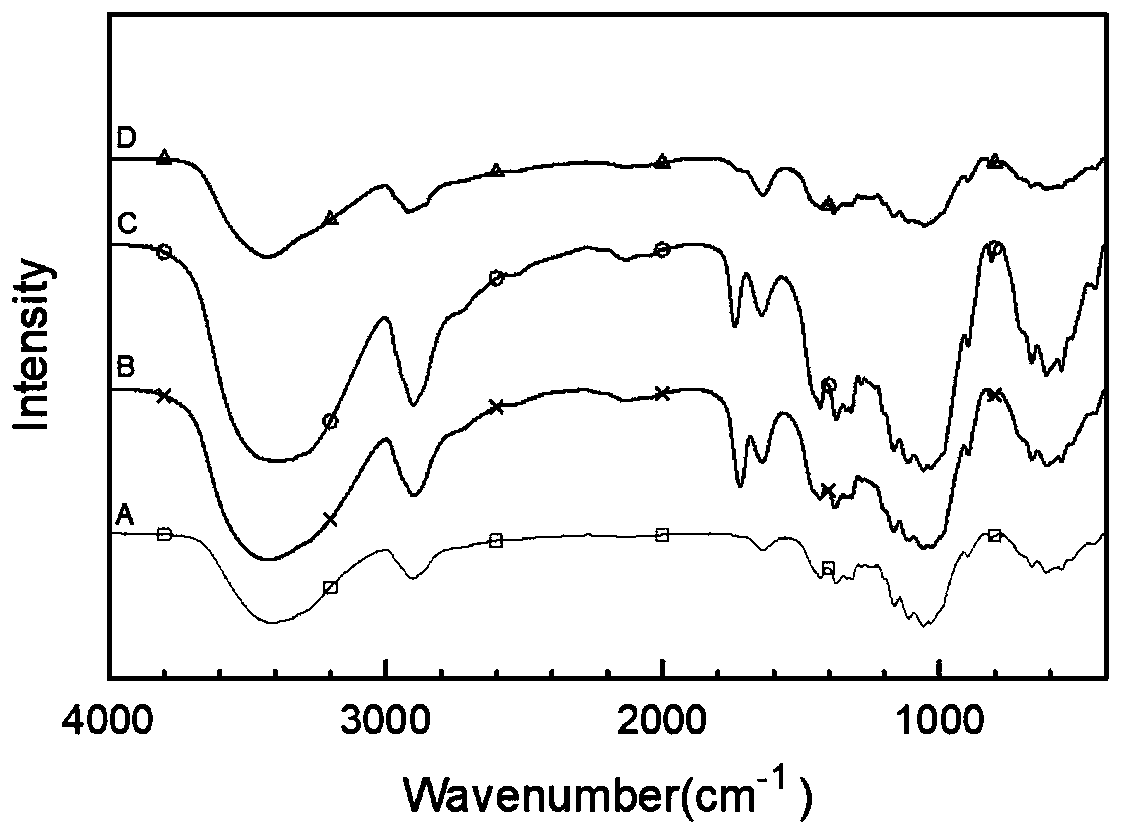

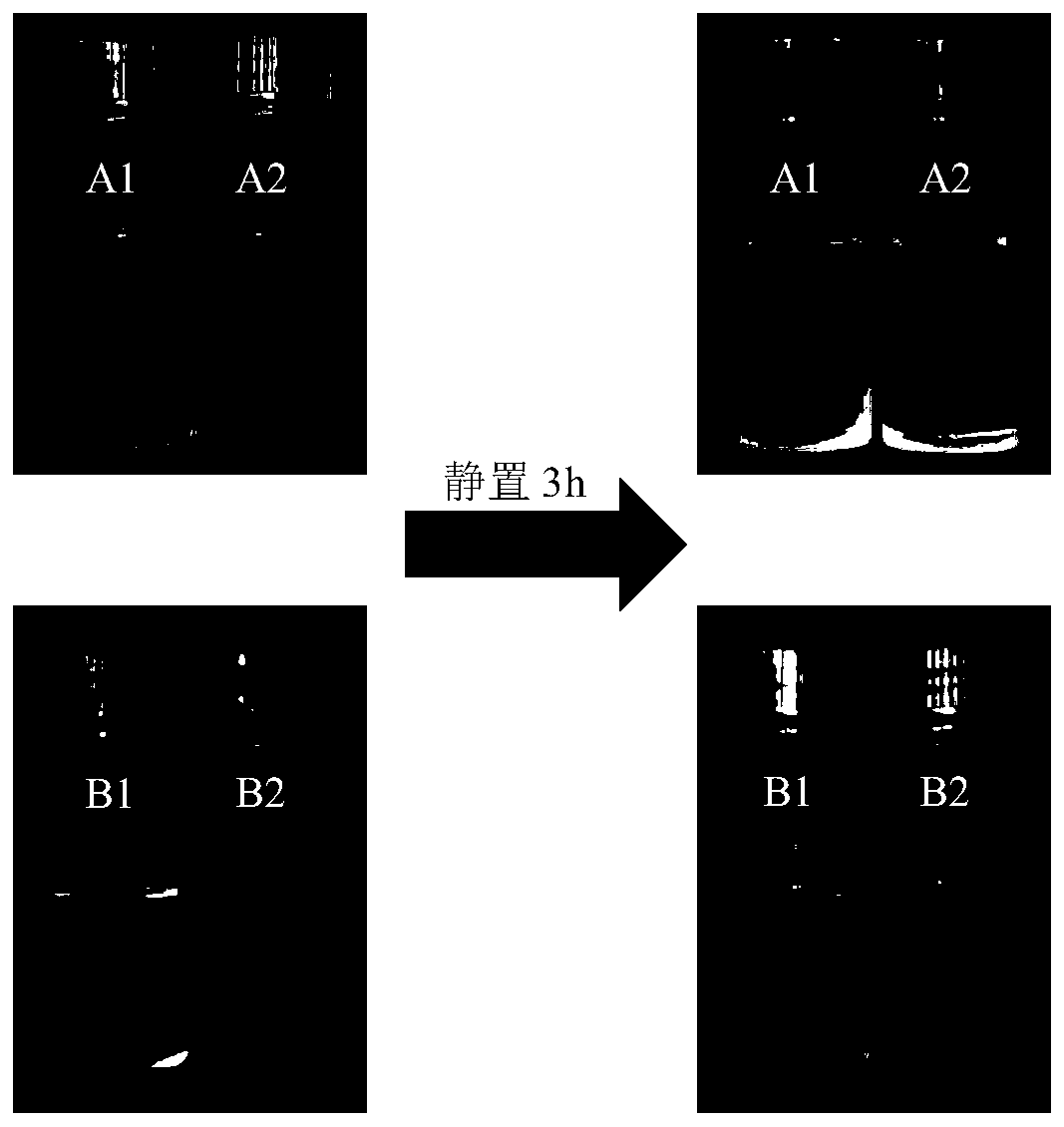

Embodiment 1

[0022] Mix the hydrogen bond acceptor choline chloride with the hydrogen bond donor lactic acid at a molar ratio of 1:9, and stir mechanically at room temperature until a uniform and stable deep eutectic solvent is obtained; take bleached hardwood pulp as the lignocellulose raw material and pass it through a deflagging machine Dissolved into cotton wool, mixed uniformly with the deep eutectic solvent at a mass ratio of 1:8, and heat-treated at 85°C for 3h; the mixture of lignocellulose and deep eutectic solvent after the swelling reaction was completed was added to the colloid mill for grinding for 40min, Obtain the deep eutectic solvent dispersion liquid of surface esterified lignocellulose nanofiber; Dispersion liquid is obtained the lignocellulose nanofiber of surface esterification (as figure 1 Shown in A), the length of the lignocellulose nanofibers is 7-12um, the width is 60-100nm, and the yield of the prepared lignocellulose nanofibers is 80-90%.

[0023] The above-ment...

Embodiment 2

[0025] The preparation of lignocellulose nanofibers, the method is the same as in Example 1, wherein, in Example 1, the hydrogen bond acceptor choline chloride in the deep eutectic solvent adopts any one of choline bromide, choline iodide or betaine substitute.

Embodiment 3

[0027] The preparation of lignocellulose nanofibers, the method is the same as in Example 1, wherein, in Example 1, the hydrogen bond donor lactic acid in the deep eutectic solvent adopts citric acid, maleic acid, oxalic acid, malonic acid, formic acid , malic acid, acetic acid any alternative.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com