Hydrogen sulfide liquid-phase oxidation removing method taking deep-eutectic solvent as medium

A technology of deep eutectic solvent and liquid phase oxidation, which is applied in chemical instruments and methods, separation methods, preparation/purification of sulfur, etc. It can solve the problems of volatile substances discharged into the atmosphere, organic amines are easy to degrade, and desulfurization efficiency is reduced. , to achieve excellent solubility, no VOCs emissions, and low operating temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

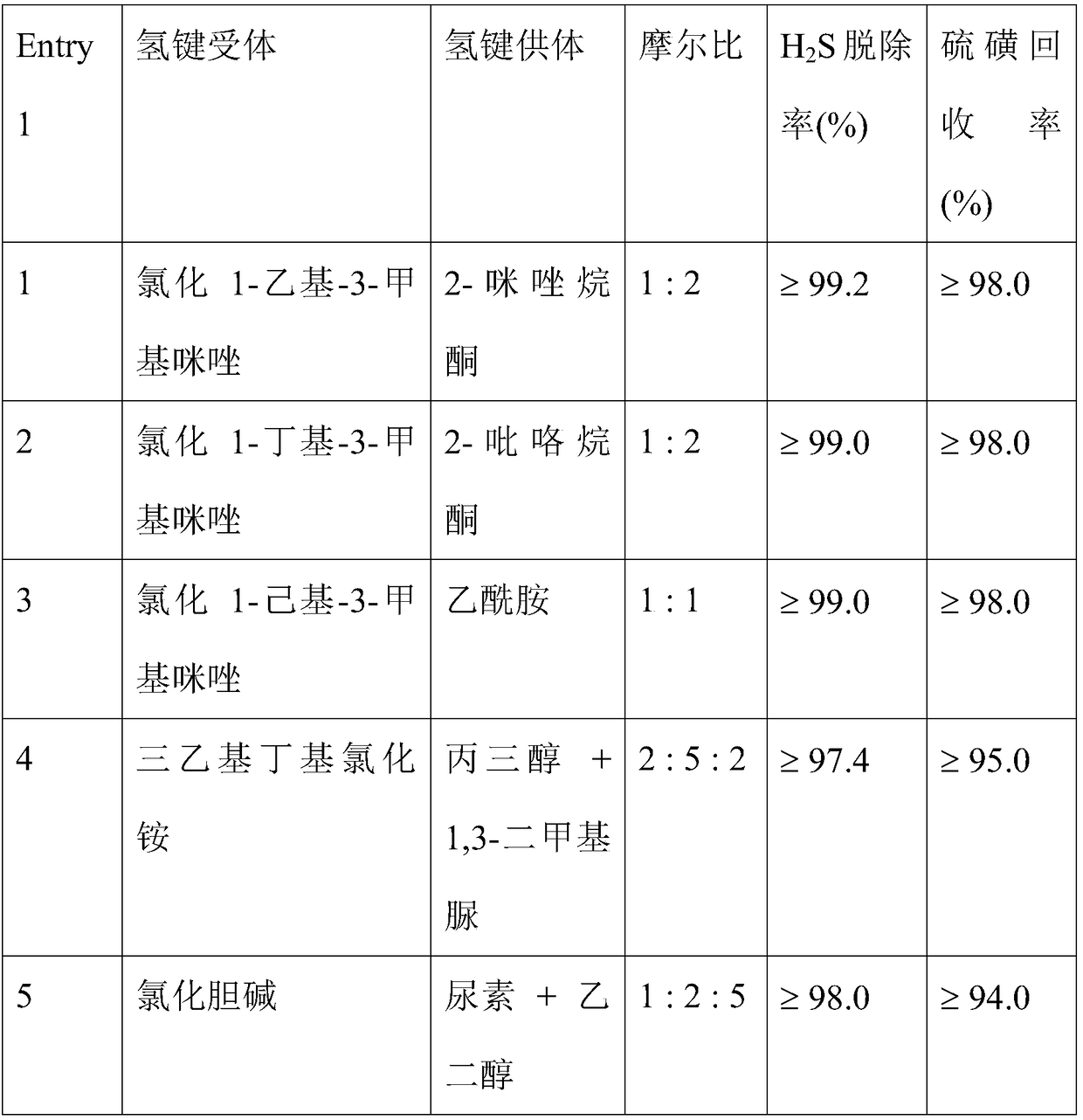

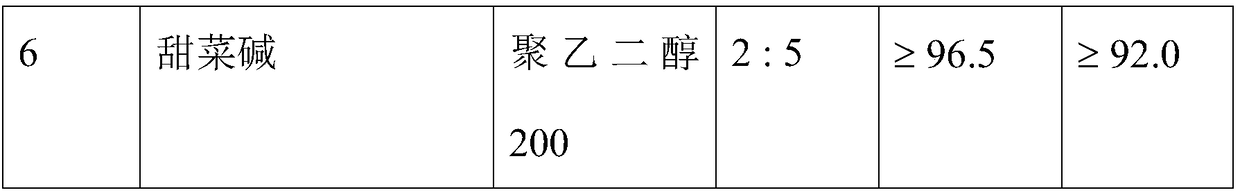

[0025] Example 1: Take the preparation of 1-ethyl-3-methylimidazol-2-imidazolidinone (molar ratio 1:2) as an example in the case of deep eutectic solvent chlorination, which is prepared by hydrogen bond donor 2-imidazolidine Ketone and hydrogen bond acceptor 1-ethyl-3-methylimidazolium chloride are mixed at a molar ratio of 1:2, stirred at 80°C until they eutectic, and the liquid obtained after cooling to room temperature is a deep eutectic solvent . The preparation method of the deep eutectic solvent used in the following examples is similar.

Embodiment 2

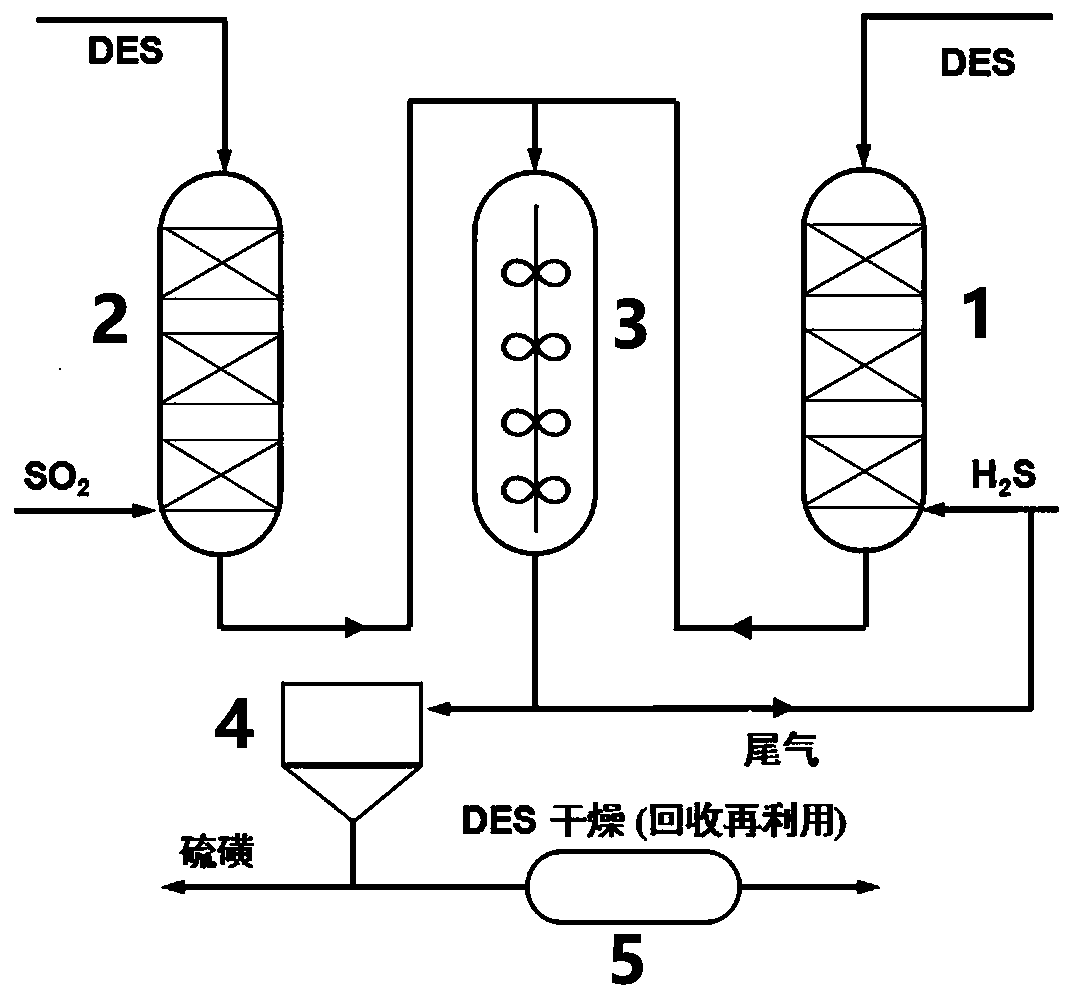

[0026] Embodiment 2: The hydrogen sulfide liquid-phase oxidation removal method using deep eutectic solvent as the medium, its method schematic diagram is shown in the appendix figure 1 , the H 2 Natural gas with a volume fraction of S of 0.8% from H 2 S is input from the bottom of absorption tower 1, and the deep eutectic solvent chlorinated 1-ethyl-3-methylimidazol-2-imidazolidinone (molar ratio 1:2) is input from the top of absorption tower 1. h 2 The operating temperature of S absorption tower 1 is room temperature, the operating pressure is 1.0MPa, and the operating liquid-gas ratio is 10Kg / Nm 3 . Will SO 2 The volume fraction of 0.2% coal combustion flue gas from SO 2 The bottom of the absorption tower 2 is input, and the deep eutectic solvent chlorinated 1-ethyl-3-methylimidazol-2-imidazolidinone (molar ratio 1:2) is input from the top of the absorption tower 2. SO 2 The operating temperature of the absorption tower 2 is room temperature, the operating pressure i...

Embodiment 3

[0027] Embodiment 3: its technique is similar to embodiment 2, see attached figure 1 , the H 2 S volume fraction of 3% coke oven gas from H 2 S is input from the bottom of absorption tower 1, and the deep eutectic solvent chlorinated 1-butyl-3-methylimidazol-2-pyrrolidone (molar ratio 1:2) is input from the top of absorption tower 1. h 2 The operating temperature of S absorption tower 1 is room temperature, the operating pressure is 1.0MPa, and the operating liquid-gas ratio is 8Kg / Nm 3 . Will SO 2 The volume fraction of 0.2% coal combustion flue gas from SO 2 The bottom of the absorption tower 2 is input, and the low co-solvent chloride 1-butyl-3-methylimidazol-2-pyrrolidone (molar ratio 1:2) is input from the top of the absorption tower 1. SO 2 The operating temperature of the absorption tower 2 is room temperature, the operating pressure is 0.1MPa, and the operating liquid-gas ratio is 40Kg / Nm 3 . The packing used in absorption towers 1 and 2 is mellapak250Y. H 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com