Preparation method of nano-nickel oxide for electrode material of supercapacitor, and nano-nickel oxide prepared by method

A technology of nano-nickel oxide and supercapacitor, which is applied in nanotechnology for materials and surface science, nickel oxide/nickel hydroxide, nanotechnology, etc., can solve the problems of time-consuming, etc., achieve short time-consuming and reduce production costs , the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Choline chloride and urea were stirred and mixed at a molar ratio of 1:2 at 75° C. to obtain a choline chloride-based deep eutectic solvent. 15.00g NiCl 2 ·6H 2 O was dissolved in 1 liter of choline chloride-based deep eutectic solvent, at this time the NiCl in the reaction solution 2 The concentration is 15g / L, and the magnetic stirring is uniform. At 130°C, quickly add 200ml of water to the above 1 liter of reaction solution. During the dropwise addition, the reaction solution was kept stirring at a high speed (greater than 750r / min), and reacted for 40 minutes. The precipitated product was separated by centrifugation, washed three times with methanol and once with deionized water, dried at 60 °C and annealed at 300 °C for 4 h to obtain the supercapacitor electrode material - flower-like nano-NiO.

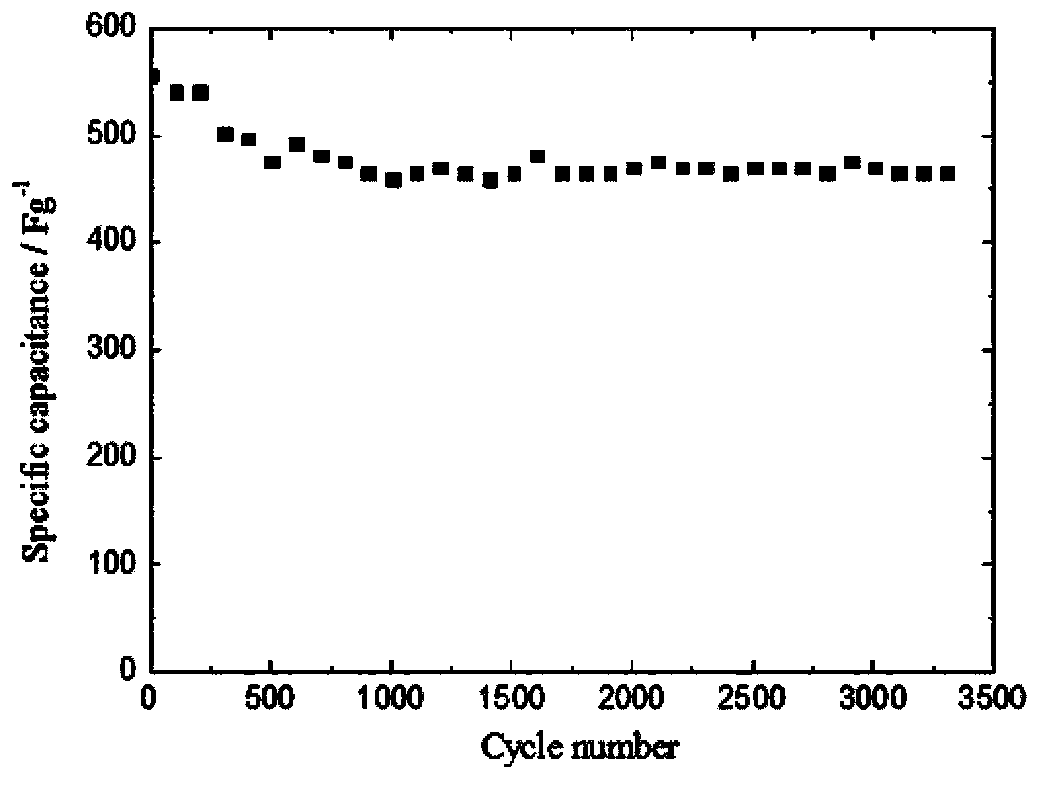

[0044] The scanning electron micrograph of the figure 1 It can be seen from the figure that the average size of flower-like nano-NiO is 100nm, and the size distributio...

Embodiment 2

[0046] Choline chloride and urea were stirred and mixed at 75° C. according to a molar ratio of 1:2 to obtain a choline chloride-based deep eutectic solvent. 20.00g NiCl 2 ·6H 2 O was dissolved in 1 liter of choline chloride-based deep eutectic solvent, at this time the NiCl in the reaction solution 2 2H 2 The concentration of O is 20g / L, and the magnetic stirring is uniform. At 140°C, quickly add 150ml of water (H 2 O), during the dropwise addition, the reaction solution was kept stirring at a high speed, and then reacted for 40min. The precipitated product was separated by centrifugation, then washed three times with methanol and once with deionized water, and finally dried at 60°C and annealed at 250°C for 4 hours to obtain flower-shaped nano-NiO with a grain size of 4-7nm and a BET specific surface area 78.5m 2 / g.

Embodiment 3

[0048] Choline chloride and urea were stirred and mixed at 75° C. according to a molar ratio of 1:2 to obtain a choline chloride-based deep eutectic solvent. 15.00g NiCl 2 ·6H 2 O was dissolved in 1 liter of choline chloride-based deep eutectic solvent, at this time the NiCl in the reaction solution 2 2H 2 The concentration of O is 15g / L, and the magnetic stirring is uniform. At 130°C, quickly add 200ml of water (H 2 O), during the dropwise addition, the reaction solution was kept stirring at a high speed, and then reacted for 40min. The precipitated product was separated by centrifugation, then washed three times with methanol and once with deionized water, and finally dried at 100°C and annealed at 350°C for 4 hours to obtain flower-shaped nano-NiO with a grain size of 5-10nm and a BET ratio of Surface area is 72.64m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com