Environment-friendly electroplate liquid for copper base plating layer and application method thereof

An electroplating solution, an environmentally friendly technology, applied in coatings, electrolytic coatings, etc., can solve problems such as environmental hazards, strong corrosion and high toxicity of electroplating solutions, and achieve the effects of smooth surface, simplified composite electroplating process, and simple components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Choline chloride and ethylene glycol were stirred and mixed at 75° C. according to a molar ratio of 1:2 to obtain a choline chloride-based deep eutectic solvent. 30 g CuCl 2 2H 2 O is dissolved in 200ml choline chloride-based deep eutectic solvent to obtain an environmentally friendly electroplating solution for copper-based coatings. The electrolytic copper is used as the anode, the brass sheet is used as the cathode, the plating voltage is 0.6V, and the temperature is room temperature. The electroplating time is 1 hour. After the electroplating is completed, the coating is washed with methanol and water in sequence, and then dried.

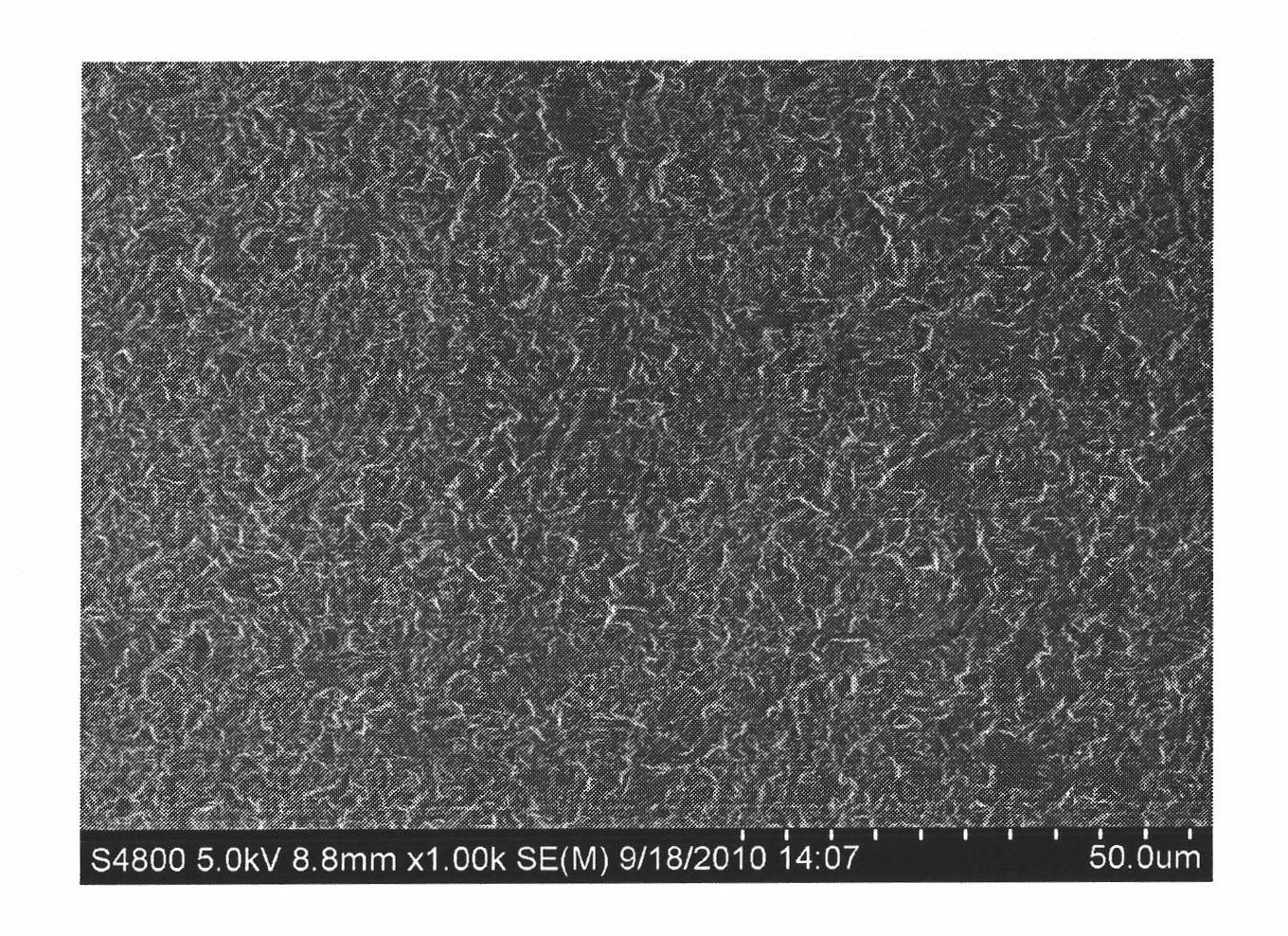

[0020] The copper coating obtained by this process is pink, with a smooth surface and a thickness of about 15 μm. The scanning electron microscope photo is as follows: figure 1 shown.

Embodiment 2

[0022] Choline chloride and urea were stirred and mixed at 75° C. according to a molar ratio of 1:2 to obtain a choline chloride-based deep eutectic solvent. 10 g CuCl 2 Dissolve in 200ml of choline chloride-based deep eutectic solvent to obtain an environmentally friendly electroplating solution for copper-based plating. The electrolytic copper is used as the anode, the brass sheet is used as the cathode, the plating voltage is 1V, and the temperature is 40°C. The electroplating time is 0.5 hours. After the electroplating is completed, the coating layer is washed with methanol and water in sequence, and dried.

[0023] The copper plating obtained by this process is rose red, with a smooth surface and a thickness of about 10 μm.

Embodiment 3

[0025] Choline chloride and ethylene glycol were stirred and mixed at 75° C. according to a molar ratio of 1:2 to obtain a choline chloride-based deep eutectic solvent. 30 g CuCl 2 2H 2 O was dissolved in 200ml of choline chloride-based deep eutectic solvent, and at the same time, 0.02g of carbon nanotubes were added to obtain an environmentally friendly electroplating solution for copper-based plating. The electrolytic copper is used as the anode, the brass sheet is used as the cathode, the plating voltage is 1.1V, and the temperature is room temperature. The electroplating time is 1 hour. After the electroplating is completed, the coating is washed with methanol and water in sequence, and then dried.

[0026] The copper plating obtained by this process is dark red, with a smooth surface and a thickness of about 12 μm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com