Method for preparing zinc oxalate as zinc oxide powder precursor from middle/low-grade zinc oxide ore

A technology for zinc oxide ore and zinc oxide powder, which is applied in the field of hydrometallurgy, can solve the problems of high energy consumption, low concentration of zinc and great environmental harm, and achieves the effects of abundant raw material sources, simple preparation and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

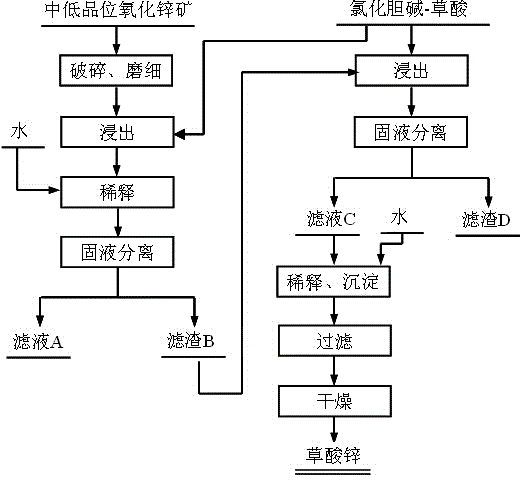

[0021] Such as figure 1 As shown, the method for preparing zinc oxide powder precursor zinc oxalate by using middle and low grade zinc oxide ore, its specific steps include as follows:

[0022] (1) choline chloride and oxalic acid are formulated into a deep eutectic solvent-based ionic liquid at a molar ratio of 1:1;

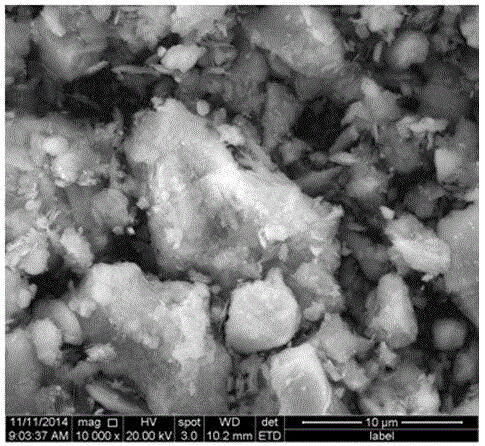

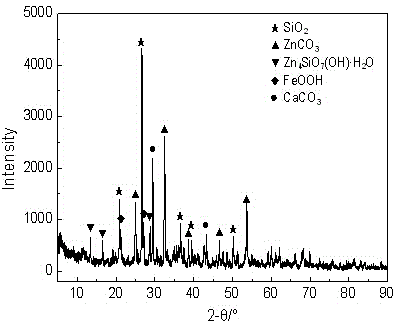

[0023] (2) Crush and grind the middle and low-grade zinc oxide ore until the particle size is less than 75 μm, and then add it to the deep eutectic solvent-type ionic liquid prepared in step (1) according to the liquid-solid ratio of 10:1 L / kg. Stir and leaching for 3 hours, add distilled water with a volume ratio of 1:4 to the leaching pulp, stir evenly and let it stand for 20 minutes, and obtain filtrate A and filter residue B rich in zinc oxalate through solid-liquid separation; The mass composition of zinc oxide ore includes: Zn13.82%, Si26.12%, Fe12.59%, Ca3.71%, Al2.60%, Mg0.41%, S0.65%. The form of zinc ore and hemimorphite exists, and the scanning elec...

Embodiment 2

[0026] Such as figure 1 As shown, the method for preparing zinc oxide powder precursor zinc oxalate by using middle and low grade zinc oxide ore, its specific steps include as follows:

[0027] (1) choline chloride and oxalic acid are formulated into a deep eutectic solvent-based ionic liquid at a molar ratio of 1:1;

[0028] (2) Crush and grind the middle and low-grade zinc oxide ore until the particle size is less than 120 μm, and then add it to the deep eutectic solvent-type ionic liquid prepared in step (1) according to the liquid-solid ratio of 10:1 L / kg. Stir and leaching for 3 hours, add distilled water with a volume ratio of 1:4 to the leaching pulp, stir evenly and let it stand for 20 minutes, and obtain filtrate A and filter residue B rich in zinc oxalate through solid-liquid separation; The mass composition of zinc oxide ore includes: Zn13.82%, Si26.12%, Fe12.59%, Ca3.71%, Al2.60%, Mg0.41%, S0.65%. The form of zinc ore and hemimorphite exists, and the scanning ele...

Embodiment 3

[0031] Such as figure 1 As shown, the method for preparing zinc oxide powder precursor zinc oxalate by using middle and low grade zinc oxide ore, its specific steps include as follows:

[0032] (1) choline chloride and oxalic acid are formulated into a deep eutectic solvent-based ionic liquid at a molar ratio of 1:1;

[0033](2) Crush and grind the middle and low-grade zinc oxide ore until the particle size is less than 180 μm, and then add it to the deep eutectic solvent-type ionic liquid prepared in step (1) according to the liquid-solid ratio of 10:1 L / kg. Stir and leaching for 3 hours, add distilled water with a volume ratio of 1:4 to the leaching pulp, stir evenly and let it stand for 20 minutes, and obtain filtrate A and filter residue B rich in zinc oxalate through solid-liquid separation; The mass composition of zinc oxide ore includes: Zn13.82%, Si26.12%, Fe12.59%, Ca3.71%, Al2.60%, Mg0.41%, S0.65%. The form of zinc ore and hemimorphite exists, and the scanning elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com