Method for recycling and regenerating lithium cobalt oxide from waste lithium ion batteries

A technology for lithium-ion batteries and regenerated lithium cobalt oxide, which is applied in the field of non-ferrous metal metallurgy, can solve problems such as high heat treatment temperature, large equipment corrosion, and poor performance of positive electrode materials, and achieve high metal recovery rate, low requirements for recovery process conditions, and The effect of low leaching temperature requirement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

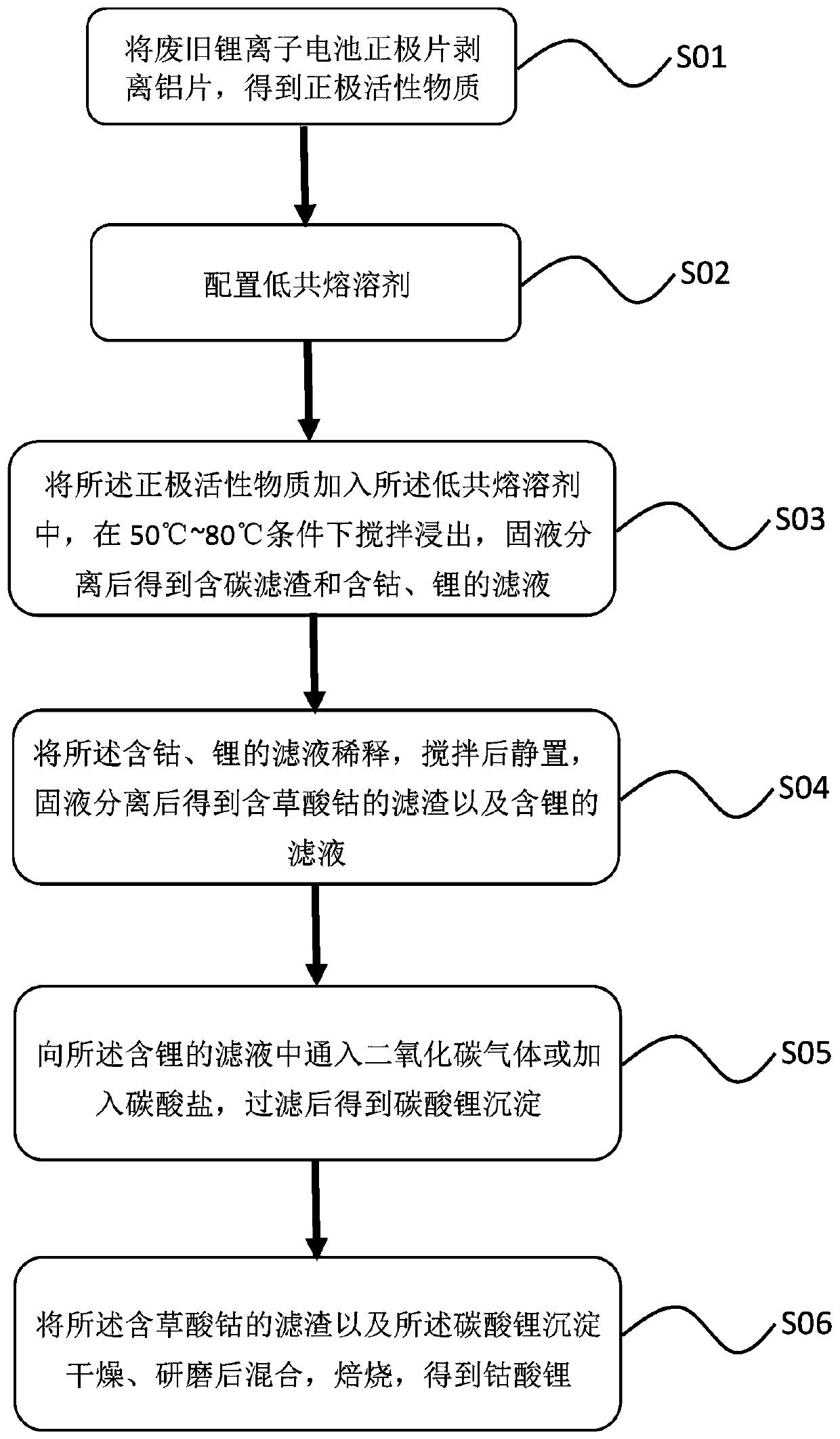

[0023] The invention provides a method for recovering and regenerating lithium cobalt oxide from waste lithium ion batteries. In an exemplary embodiment of the method for recovering and regenerating lithium cobaltate in the waste lithium-ion battery of the present invention, as figure 1 Shown, described preparation method comprises:

[0024] S01, peeling off the aluminum sheet from the positive electrode sheet of the waste lithium-ion battery to obtain the positive electrode active material;

[0025] S02, preparation of deep eutectic solvent;

[0026] S03, adding the positive electrode active material into the deep eutectic solvent, stirring and leaching at 50°C to 80°C, and obtaining carbon-containing filter residue and filtrate containing cobalt and lithium after solid-liquid separation;

[0027] S04, diluting the filtrate containing cobalt and lithium, stirring and standing, and obtaining a filter residue containing cobalt oxalate and a filtrate containing lithium after s...

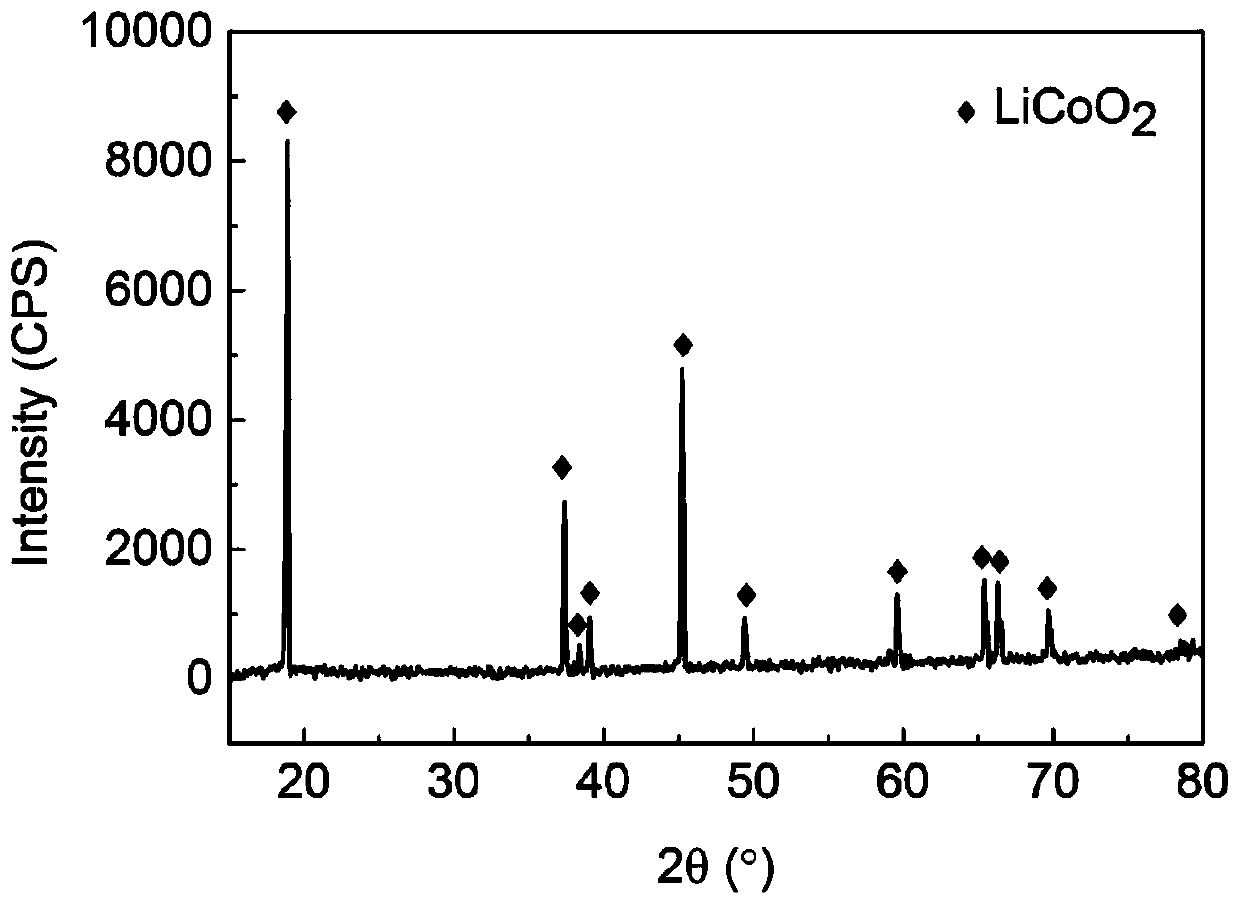

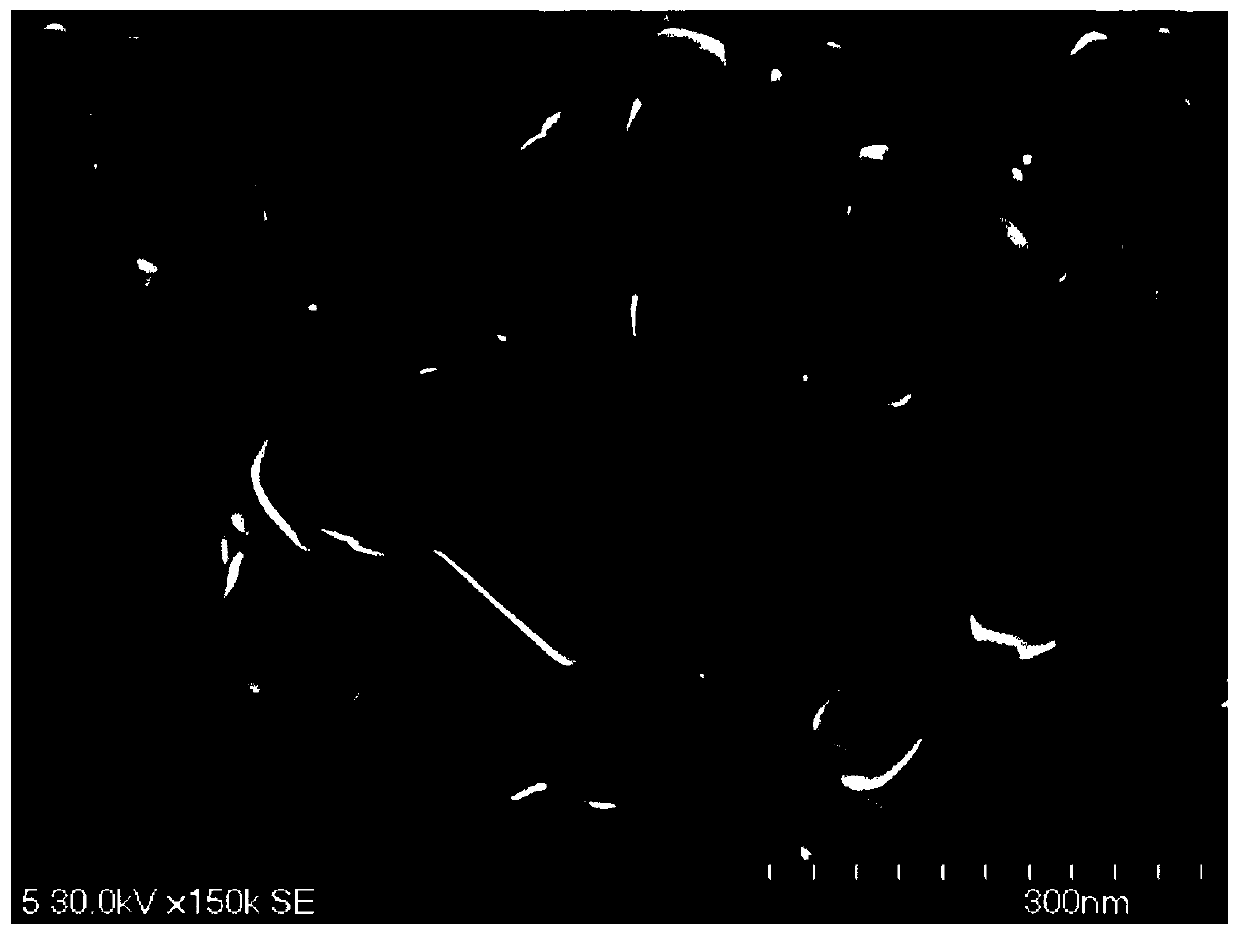

example 1

[0042] (1) Fully discharge the waste lithium-ion battery, disassemble it to obtain the waste positive electrode sheet, then place it in a high-temperature furnace, heat-treat it at a temperature of 550°C for 1 hour, peel off the aluminum sheet, and obtain the positive electrode active material, wherein the positive electrode active material Lithium cobaltate.

[0043] (2) Choline chloride and oxalic acid are formulated into a choline chloride-oxalic acid deep eutectic solvent according to a molar ratio of 1:1.

[0044] (3) Add the lithium cobaltate positive electrode active material obtained in step (1) to the deep eutectic solvent prepared in step (2), stir and leach for 5 hours at 50°C, and separate solid and liquid to obtain carbon filter residue and Cobalt, lithium metal filtrate.

[0045] (4) Add distilled water to the filtrate obtained in step (3) to dilute, stir evenly and let stand for 20min, obtain cobalt oxalate filter residue A and lithium-containing solution B thr...

example 2

[0049] (1) Fully discharge the waste lithium-ion battery, disassemble it to obtain the waste positive electrode sheet, then place it in a high-temperature furnace for heat treatment at a temperature of 550° C. for 1 hour, peel off the aluminum sheet, and obtain the positive electrode active material, wherein the positive electrode active material is Lithium manganese cobaltate.

[0050] (2) Choline chloride and oxalic acid are formulated into a choline chloride-oxalic acid deep eutectic solvent according to a molar ratio of 1:1.

[0051] (3) adding the lithium manganese cobaltate positive electrode active material obtained in step (1) to the deep eutectic solvent prepared in step (2), stirring and leaching for 2 hours at 80° C., and solid-liquid separation to obtain carbon filter residue and Filtrate containing cobalt, lithium and other metals.

[0052] (4) Add distilled water to the filtrate obtained in step (3) to dilute, stir evenly and let stand for 10min, obtain mixture ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com